Pressure detection device and method based on polymer optical fiber junction sensor

A detection device and detection method technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as shortage, and achieve the effects of stable performance, good flexibility, and rich application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

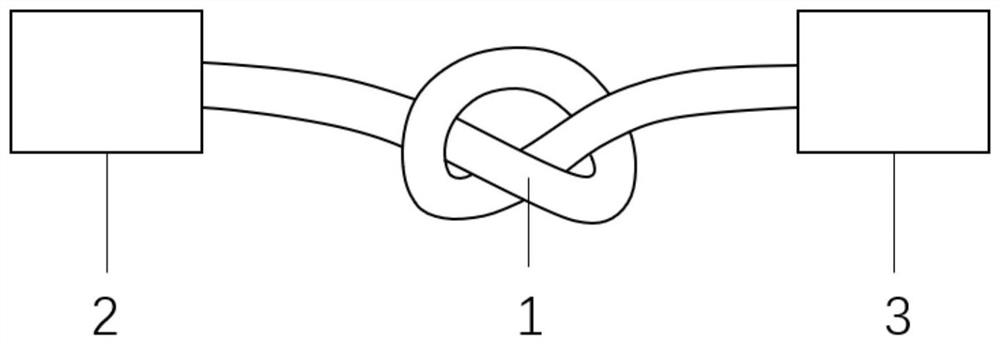

[0032] Such as figure 1 As shown, the device includes a knotted polymer optical fiber arranged at the desired pressure detection position, the polymer optical fiber has a core and a cladding, the polymer optical fiber is knotted, and the optical fiber overlap formed at the knot is a fiber knot. The optical fiber overlap is tested by applying pressure.

[0033] In a specific implementation, the polymer optical fiber is knotted into a half-knot, and the knotted position of the polymer optical fiber is located in the middle of the polymer optical fiber.

[0034] In a specific implementation, a light source and a detector are also included, and the two ends of the polymer optical fiber are respectively connected to the light source and the detector. The polymer optical fiber is buried in the flexible polymer, and the flexible polymer is pressed to drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com