Bolt tightening method

A bolt, rotary tightening technology, applied in non-electric variable control, instrument, torque/mechanical power control and other directions, can solve the problems of preload deviation, friction coefficient cannot be well controlled, etc., to achieve control, The effect of good control and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Before explaining the technical solution of the present invention, several basic concepts in this field are described.

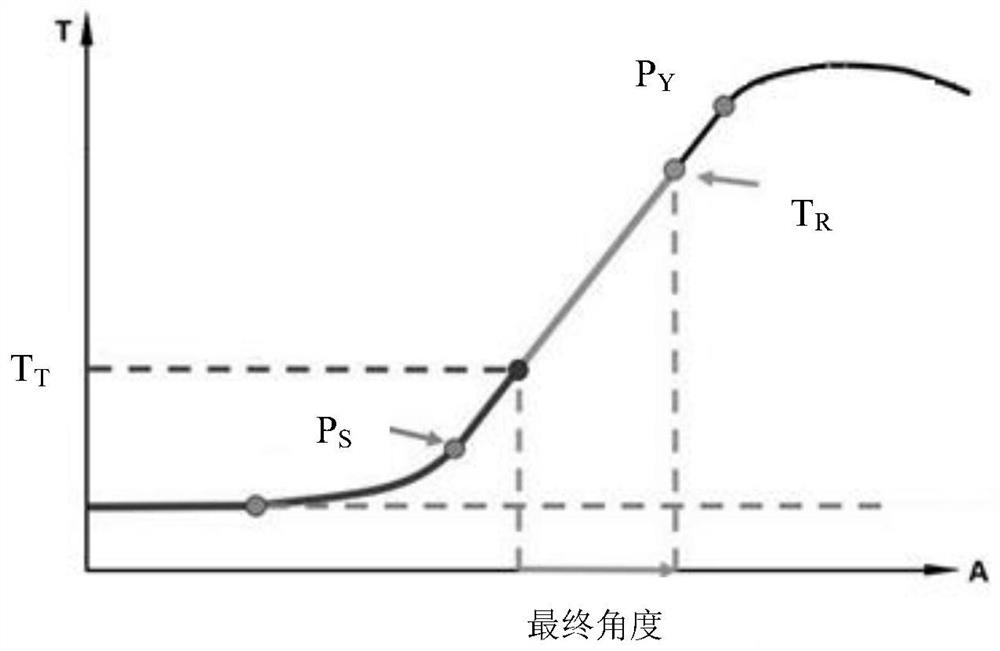

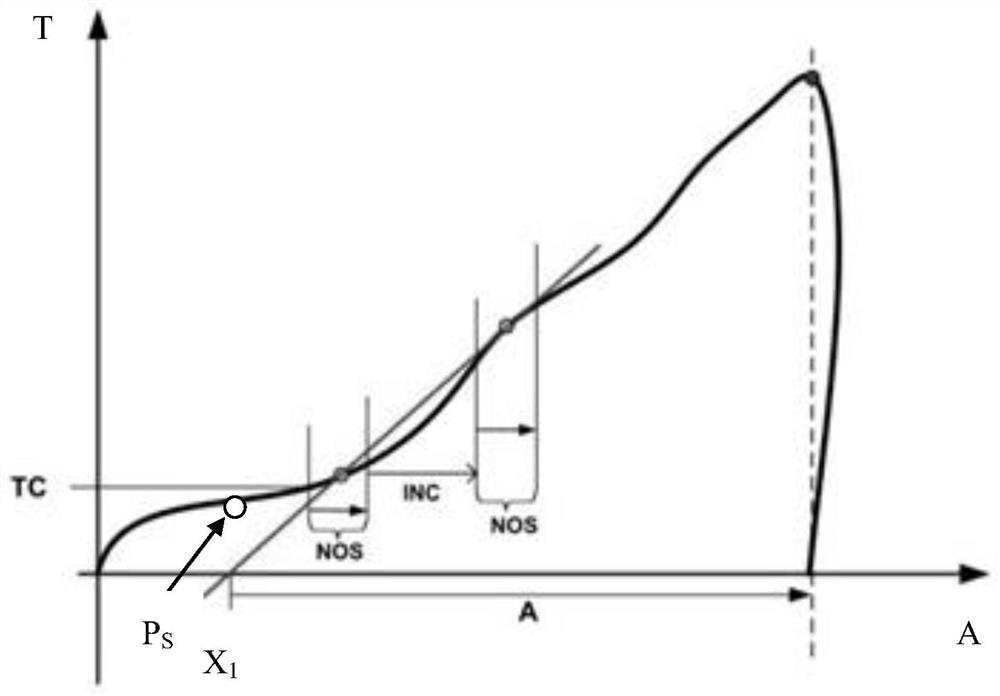

[0031] The torque tightening method and the torque + angle method are the most widely used in the manufacturing process of automobile engines. Compared with the torque tightening method, the torque + angle method reduces the influence of friction on the preload and can obtain a more stable axial force. However, whether it is the torque tightening method or the torque + angle method, all or part of the tightening process is controlled by torque in the control process, that is, there is a threshold torque (Threshold Torque) T T .

[0032] For details, please refer to figure 1 , which is a schematic diagram of the torque + angle method bolt tightening curve. Threshold torque T T Need to fall within the elastic clamping (Elastic Clamping) range, greater than the bonding point P S Torque at (Snug Point). Threshold torque T T Previously known as the "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com