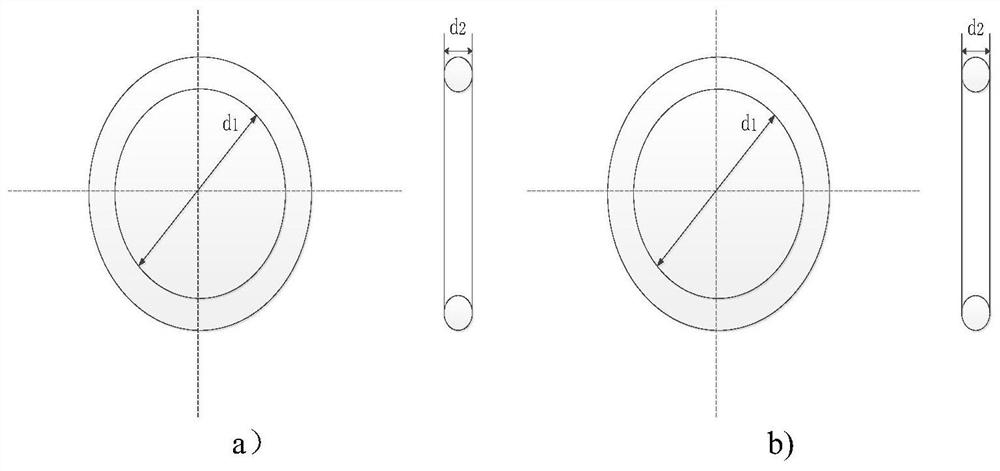

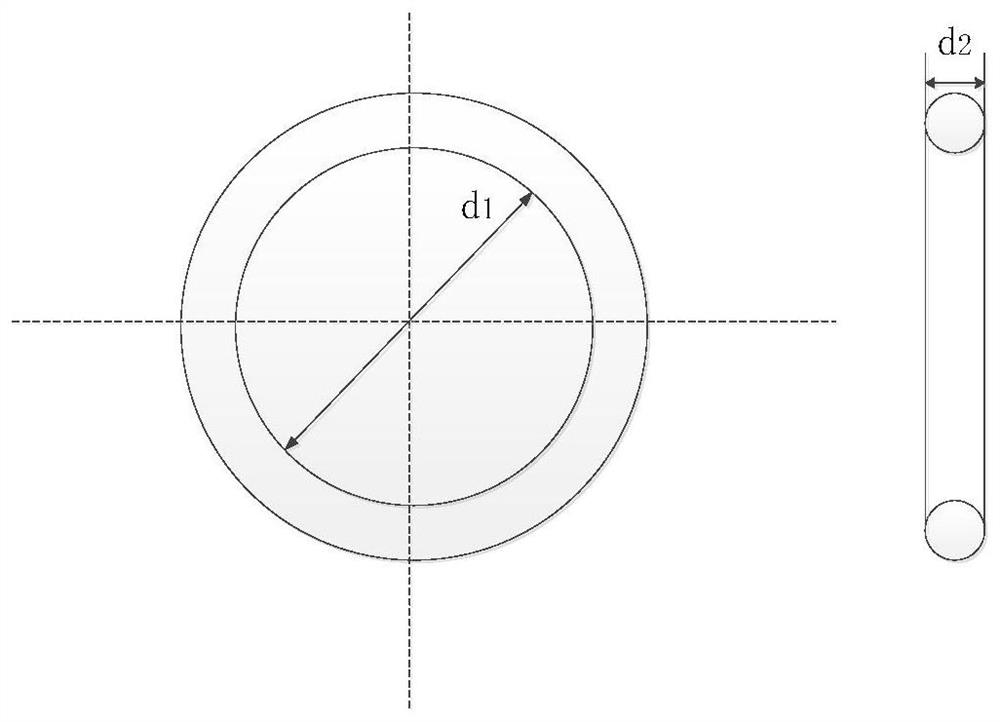

O-shaped sealing ring size measurement method based on monocular vision

An O-ring and visual measurement technology, applied in the field of visual measurement, can solve problems such as limitations, easy introduction of errors, and increase in the complexity of the calibration algorithm, achieving the effect of obvious contrast and simple re-calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0038] The O-ring size measurement method based on monocular vision provided by the present invention, such as Figure 4 As shown, it specifically includes the following steps:

[0039] Step 1. Use a 6-megapixel baslerUSB industrial camera, an industrial lens, a Win7 computer, and a ring LED light source to build a visual measurement system for sealing rings, and calibrate the visual measurement system;

[0040] Step 2, collecting the image information of the O-ring, and preprocessing the image information to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com