A Compliant Control Method of Robot Joint Servo Motor

A robot joint and compliance control technology, which is applied in the direction of motor generator control, motor control, AC motor control, etc., can solve the problems of slow system adjustment time and overshoot, so as to solve the problem of overshoot, reduce dynamic adjustment time, Effect of Improving Dynamic Scaling Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

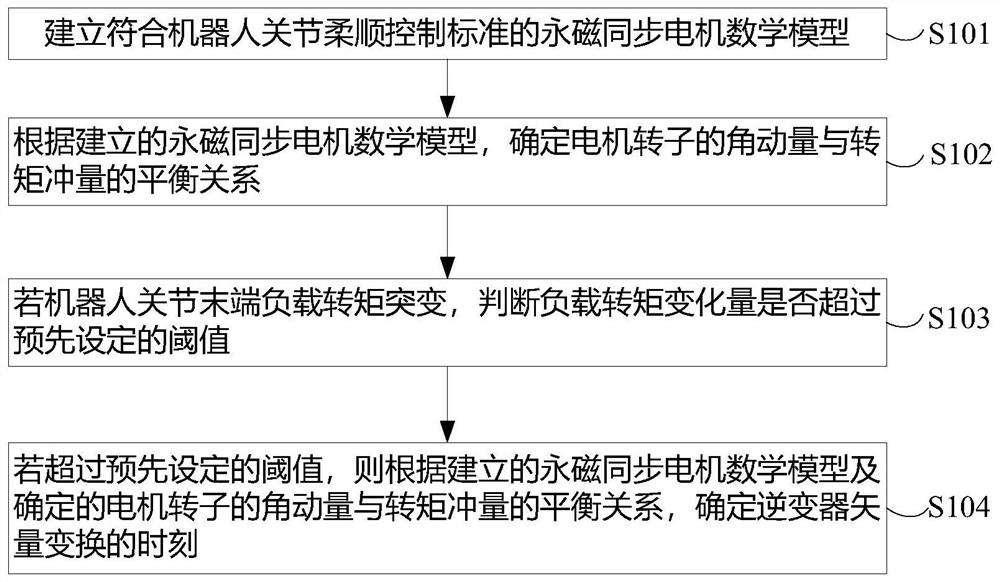

[0061] like figure 1 As shown, the embodiment of the present invention provides a robot joint servo motor compliance control method, the method includes:

[0062] S101, establishing a permanent magnet synchronous motor mathematical model that meets the robot joint compliance control standard;

[0063] S102, according to the established mathematical model of the permanent magnet synchronous motor, determine the balance relationship between the angular momentum of the motor rotor and the torque impulse;

[0064] S103, if the load torque at the end of the robot joint changes suddenly, determine whether the load torque variation exceeds a preset threshold;

[0065] S104, if the preset threshold value is exceeded, determine the time for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com