Intelligent automatic detection equipment for pulling sheet at air outlet of automobile air conditioner

An automobile air-conditioning and automatic detection technology, applied in measuring devices, instruments, sorting, etc., can solve problems such as low intelligence and waste of human resources, improve the accuracy of results, avoid invalid detection, and avoid waste of human resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

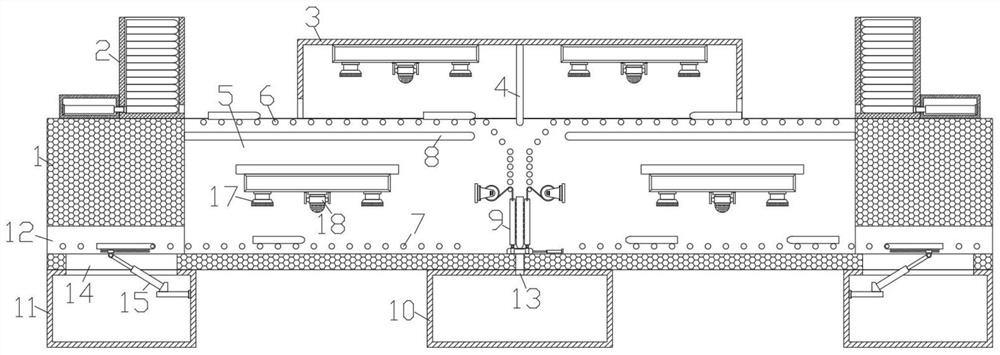

[0042] See Figure 9 As shown, the separator 4 divides the internal space of the detecting case 3 into two detection regions, the area located on the left side of the separator 4 is the detection region A, located on the right side of the separator 4 is the detection area B, weighing detection The mechanism 9 divides the conveying groove 5 into two detection regions, the area located on the left side of the weighing detecting mechanism 9 is the detection region C, the area located on the right side of the weighing detecting mechanism 9 is the detection area D;

[0043] When the kick is delivered on the left side, the first detecting mechanism performs surface detection on the detecting region A, and the camera 17 of the first detecting mechanism performs image capturing and shooting. The image is transmitted to the surface detection module for detection analysis. If the detection result is a surface qualified, the kick is entered into two rotating clamps between the two rotating cl...

Embodiment 2

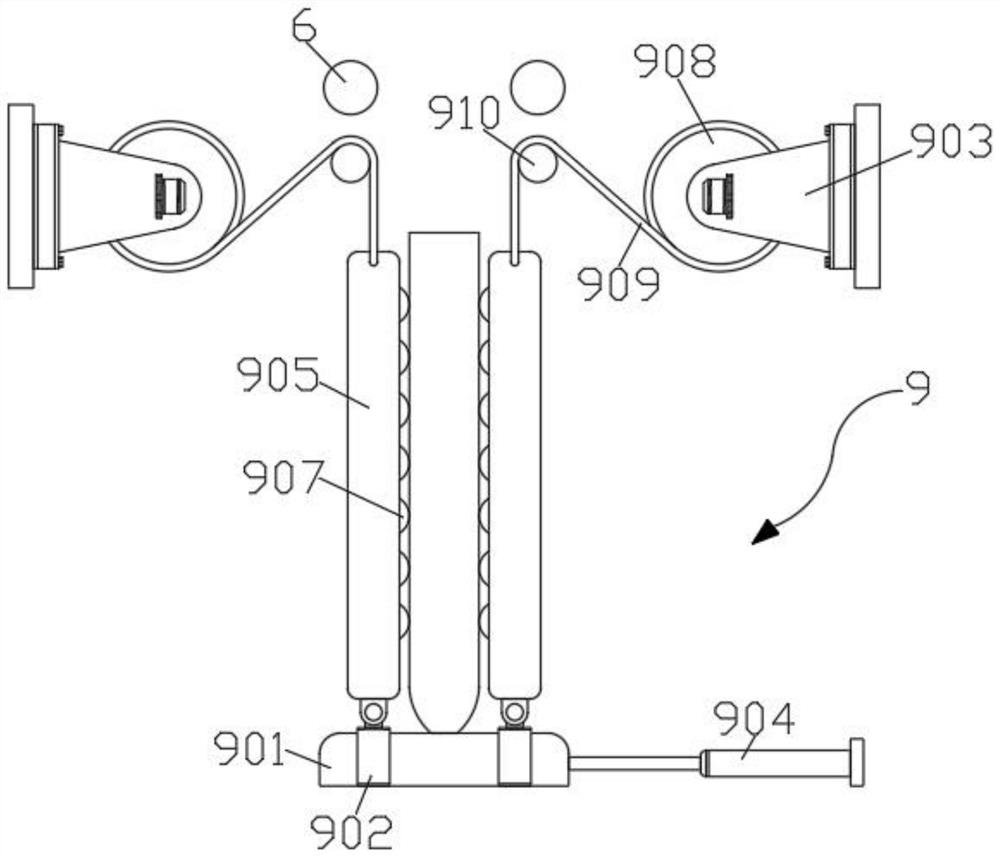

[0049] See Figure 10 As shown, the inner side wall of the conveying groove 5 is provided with a processor, the processor communication is connected to the surface detection module, the weight detection module, the storage module, and the controller, the output terminal of the controller and the second electric push rod 904, the third electric push rod. 1502, drive motor, and an input of the drive motor;

[0050] The specific process of surface detection analysis of the surface detection module on the tick includes the following steps:

[0051] Step S1: Magnify the image captured by the camera 17 to a pixel image, labeled the resulting pixel image as a contrast image, and the pixel mark of the contrast image is I, I = 1, 2, ..., N, the contrast image The image processing obtains the gradation value of the pixel gray value of the image and is marked as HDI;

[0052] Step S2: After acquiring the grayscale threshold HDmax by the storage module, the HDI is compared to the grayscale thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com