Machining equipment of aluminum alloy extrusion parts and machining technology of aluminum alloy extrusion parts

A processing equipment, aluminum alloy technology, applied in the field of aluminum alloys, can solve the problems of reducing the surface temperature of aluminum alloys, poor stability of aluminum alloys, affecting processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

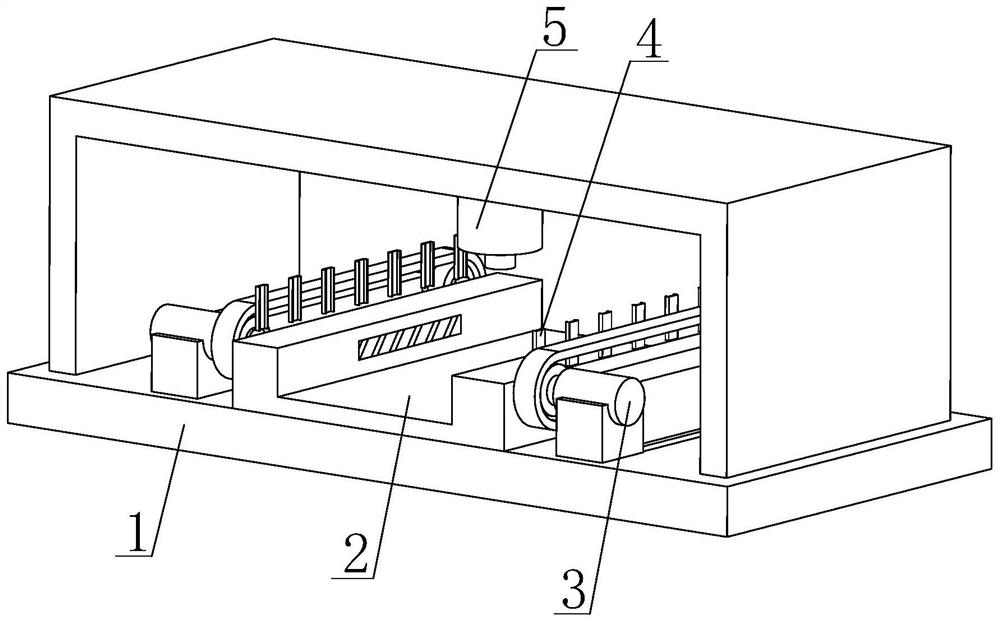

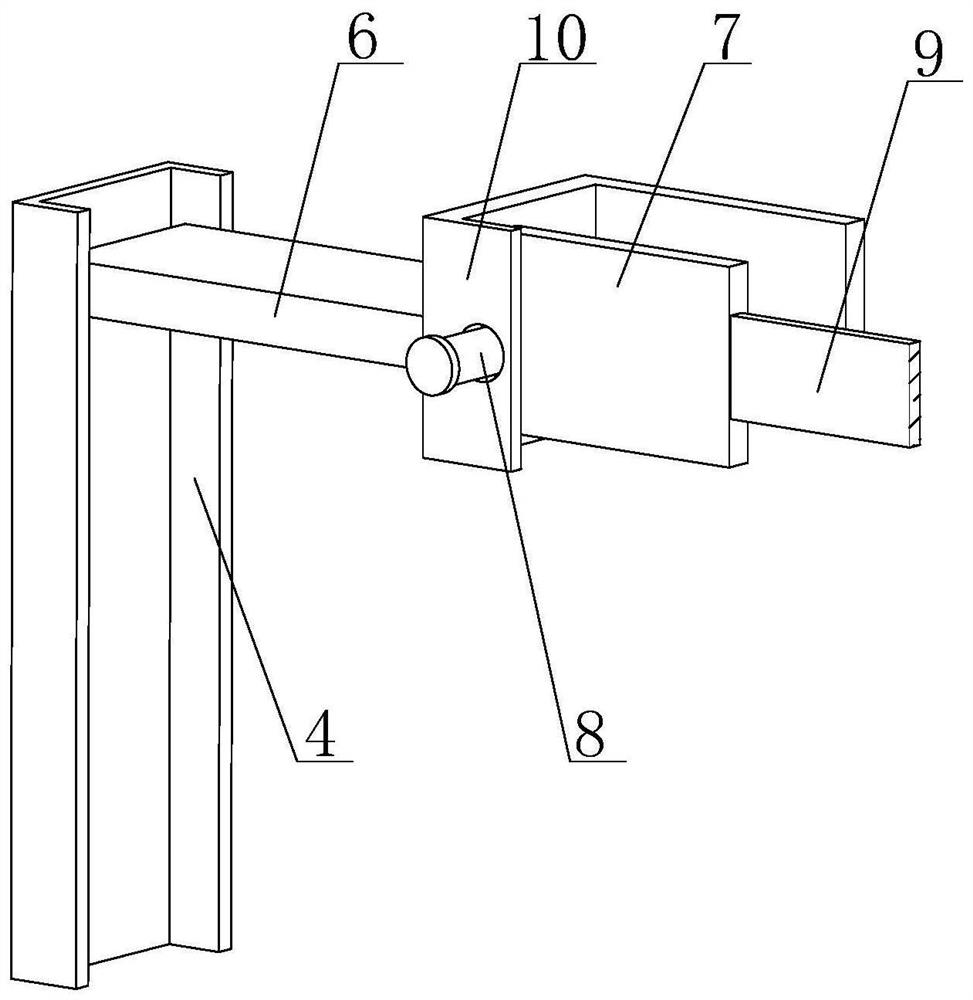

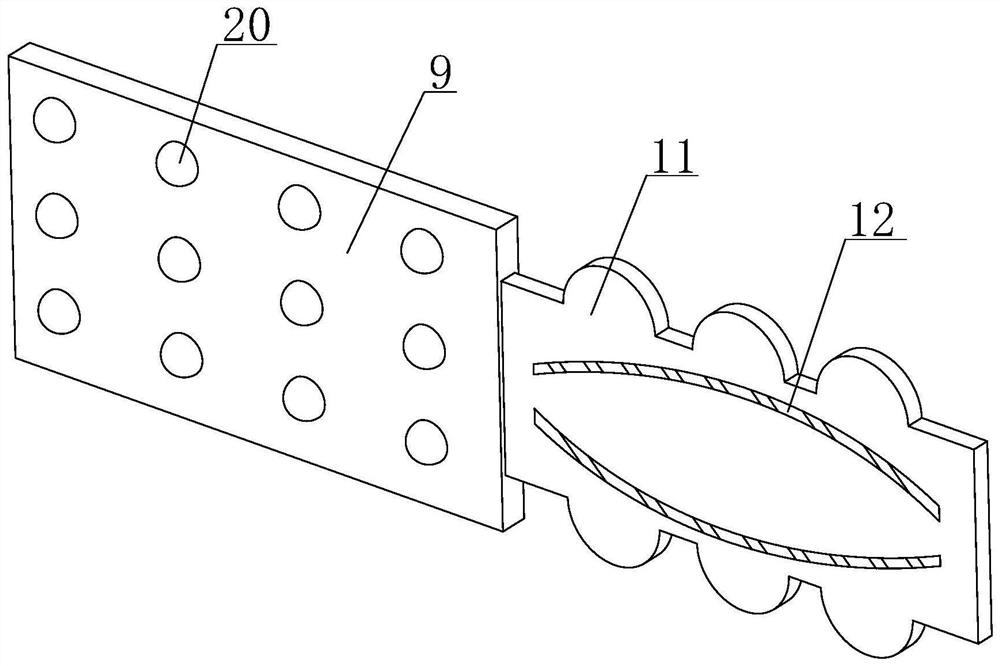

[0035] Such as Figure 1-6 As shown, in the first aspect, the present invention provides a processing equipment for aluminum alloy extruded parts, including an equipment processing bearing body 1, a processing table 2, a driving chamber 3 and a stamping power chamber 5, and the processing table 2 is fixedly installed on the equipment processing bearing On the top of the main body 1, the driving end of the driving chamber 3 is meshed with a gear belt, and the outer wall of the gear belt is threadedly connected with a mounting piece 4. The driving chamber 3 can drive the rotation of the gear belt, and then can drive the mounting piece 4 to move horizontally. The upper part of the processing table 2 is provided with a stamping power chamber 5, and the right side of the mounting part 4 is slidably connected with a side slider 6, and the right end of the side slider 6 is fixedly installed with a concave force bearing block 10, and the concave force bearing The right side of the for...

Embodiment 2

[0039] Such as Figure 1-6As shown, in the second aspect, the present invention provides a processing technology for aluminum alloy extrusions, including the processing equipment described in any one of the above-mentioned first aspects, including the following steps:

[0040] Step 1: First put the aluminum alloy on the back side of the bonding plate 9, at this time, turn the pre-tightening rod 8 to drive the contact plate 7 and the bonding plate 9 to move, so that the aluminum alloy moves together with the bonding plate 9, and finally the aluminum alloy passes through The fitting plate 9 is squeezed and fixed on the concave force bearing block 10;

[0041] Step 2: Secondly, the power provided by the drive chamber 3 drives the gear belt to rotate, and at the same time drives the aluminum alloy to move to the bottom of the stamping power chamber 5;

[0042] Step 3: At this point, the stamping power chamber 5 can be started, and the aluminum alloy can be extruded by the power g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com