Storage type quick counterweight system for whole package of cone yarns and using method of storage type quick counterweight system

A bobbin and counterweight technology, which is applied in the field of storage-type rapid counterweight system, can solve the problems that the counterweight process is not connected with the packaging process, cannot supply the bobbin in time, increases labor costs, etc., and achieves saving counterweight time, The effect of high degree of automation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

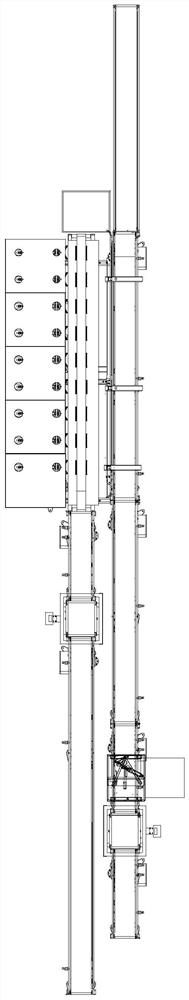

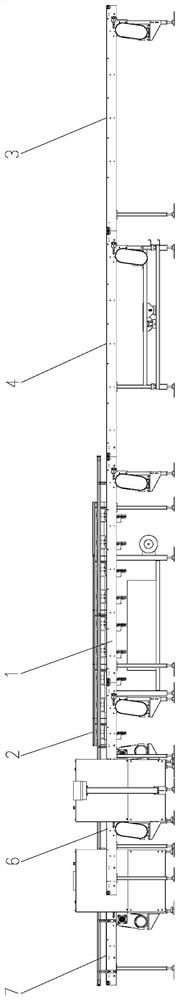

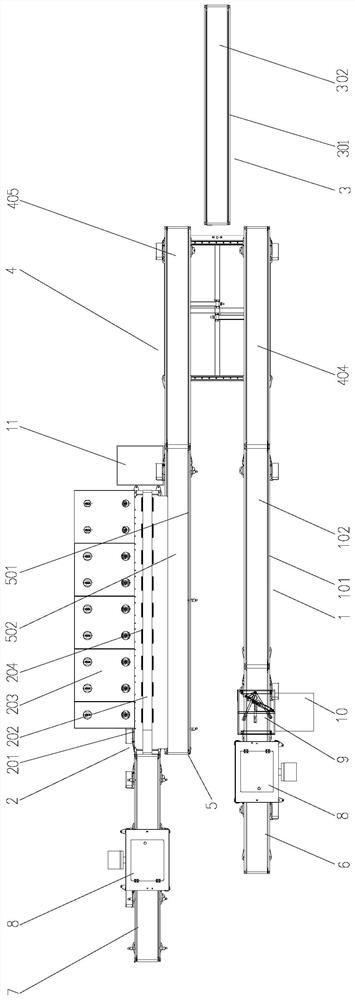

[0039] refer to figure 2 and image 3 , a storage-type rapid counterweight system for package packaging of packaged yarns provided in this embodiment, comprising a main package yarn conveying device 1, a counterweight packaged yarn conveying device 2, a packaged package conveying device 3, and a temporary package of package yarns Device 4, counterweight bobbin auxiliary conveying device 5 and control system, the main bobbin conveying device 1 and the counterweight bobbin conveying device 2 are arranged side by side, and the counterweight bobbin auxiliary conveying device 5 is arranged near the counterweight bobbin conveying device 2 On one side of the main package yarn delivery device 1, the package yarn temporary storage device 4 is arranged between the main package yarn delivery device 1, the counterweight package yarn auxiliary delivery device 5 and the package yarn packaging delivery device 3, and the package yarn temporary storage device 4 And the bobbin conveying direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com