Drilling installation; Handling system, method for independent operations.

A handling system and drilling technology, which is applied to drilling equipment, supporting devices, drilling pipes, etc., and can solve problems such as high cost rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

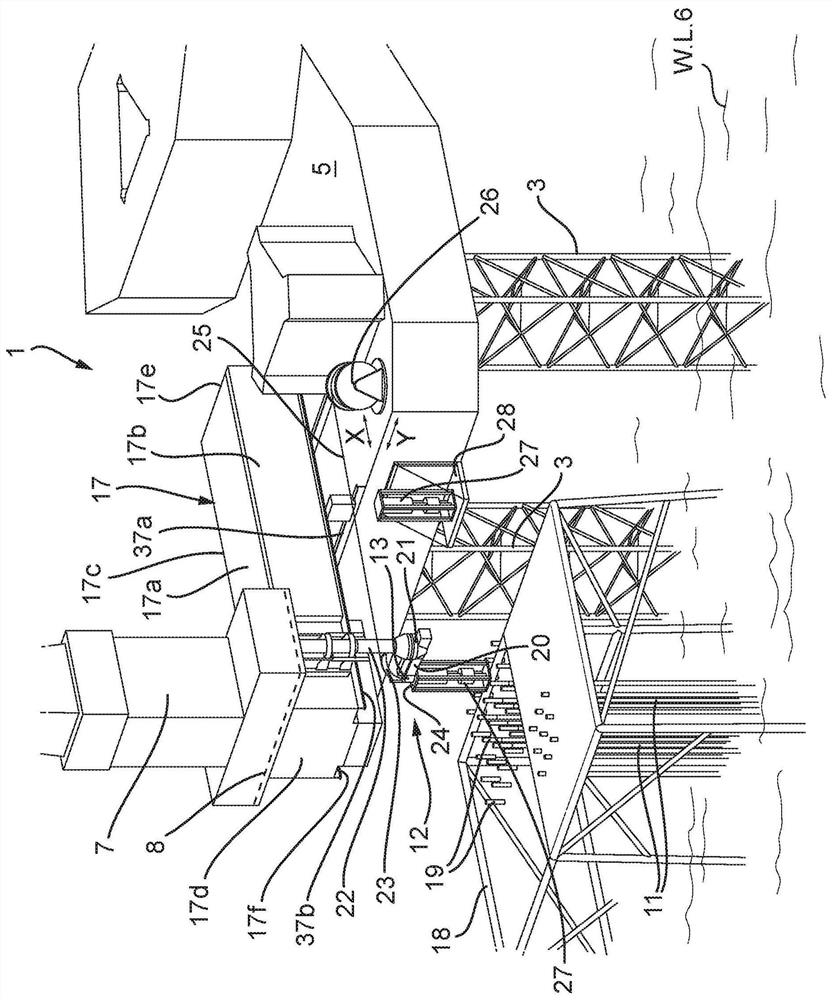

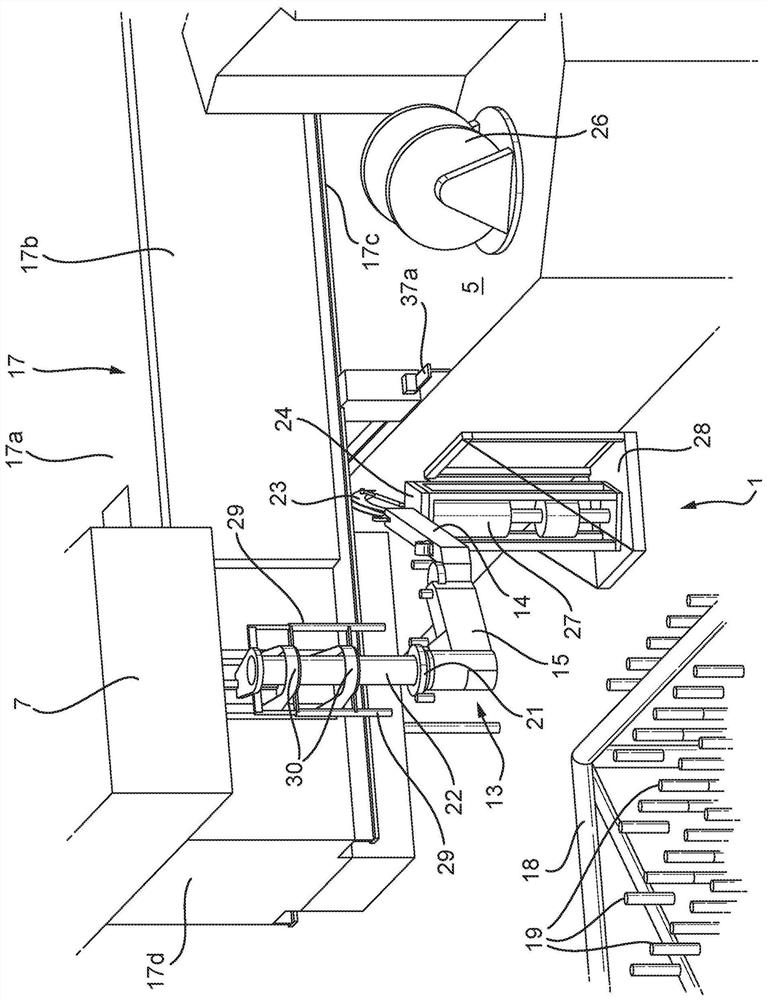

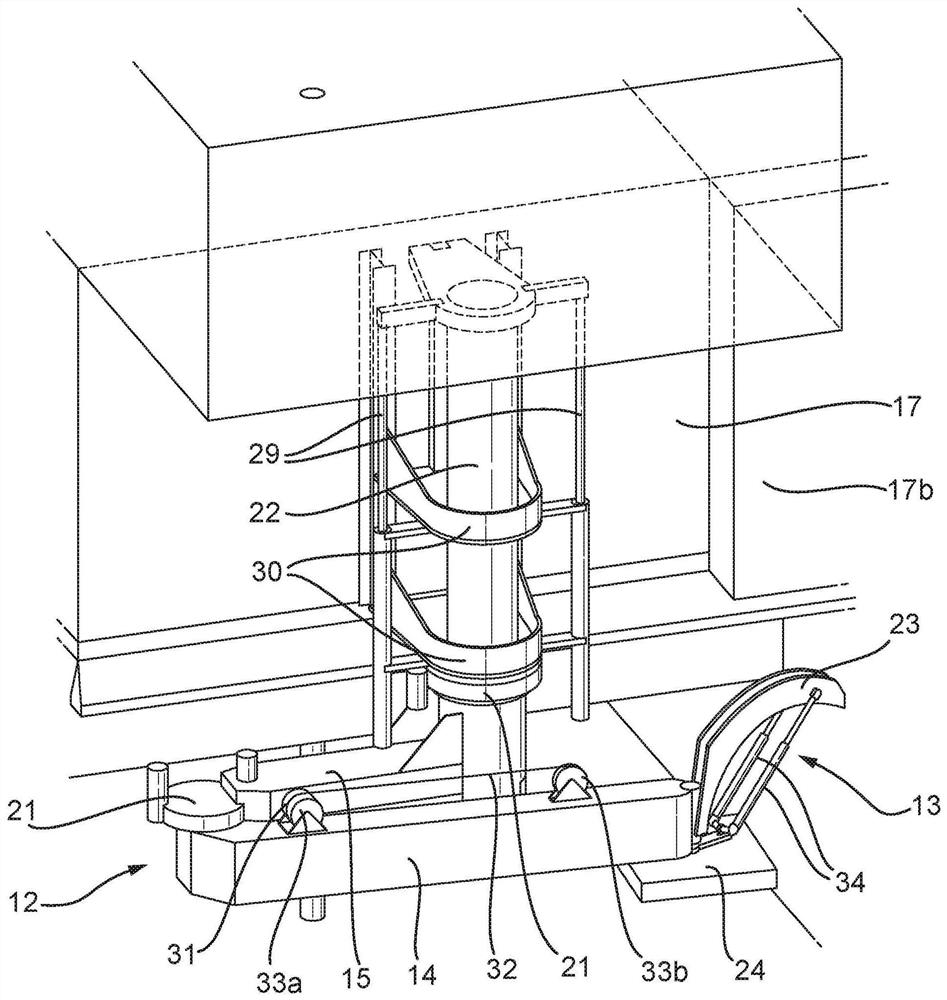

[0067] figure 1 A schematic perspective view of the drilling device 1 is shown. Here, the drilling device 1 is implemented as a jack-up platform. Such drilling rigs 1 are usually placed temporarily at offshore locations next to well platforms 18 producing oil and / or gas fields. The drilling device 1 may be used for drilling wells when exploring oil and / or gas fields, and may be used for well maintenance or repair and / or for well intervention during well production.

[0068] figure 1 A schematic perspective view of a drilling arrangement 1 comprising a cantilever beam 17 is shown. Here, the mast 7 is positioned above the cantilever beam 17 . The drill floor 8 is located at the upper side 17 a of the outrigger beam 17 . The cantilever beam 17 also has a lateral side 17b, a lateral side 17c, a rear side 17d, a front side 17e and a bottom side 17f.

[0069] A moon pool 10 (not visible in the figure) is provided through the opening of the cantilever beam 17 through which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com