Medium-thick ore body V-shaped top pillar sublevel rock drilling stage open stoping subsequent filling mining method

A filling mining method and thick ore body technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of increased ore loss and dilution rate, caving, and caving in the process of two-step stope mining, and achieve The process is simple, the connection rate is high, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the various embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them; based on the embodiments of the present invention, All other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

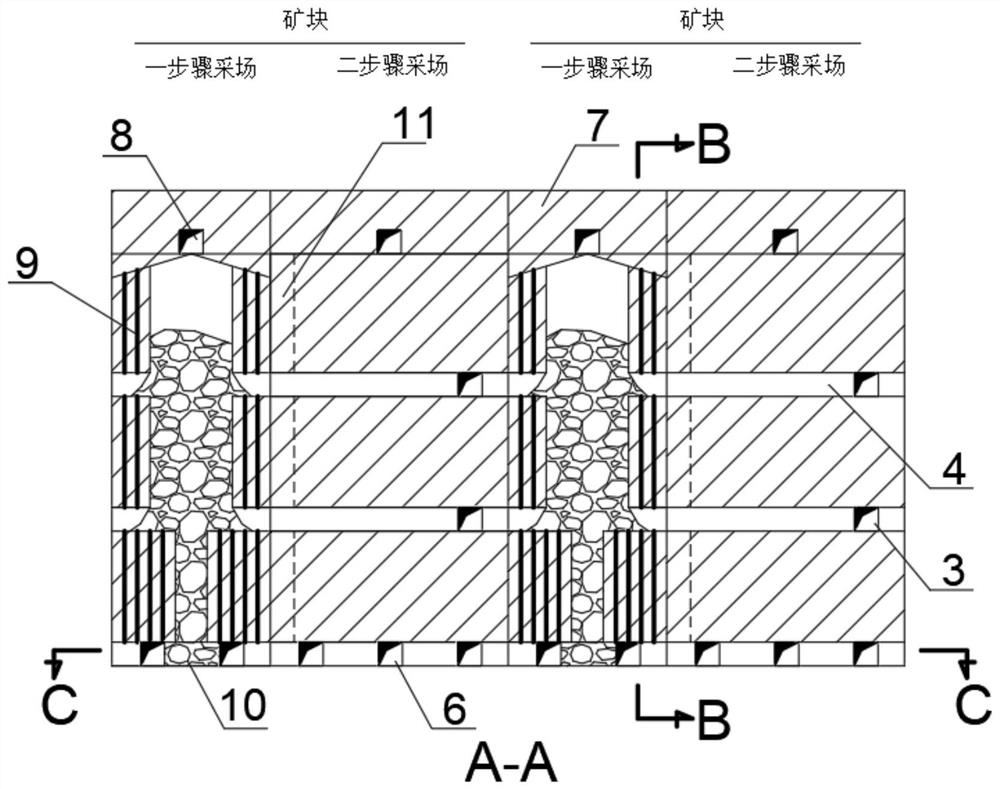

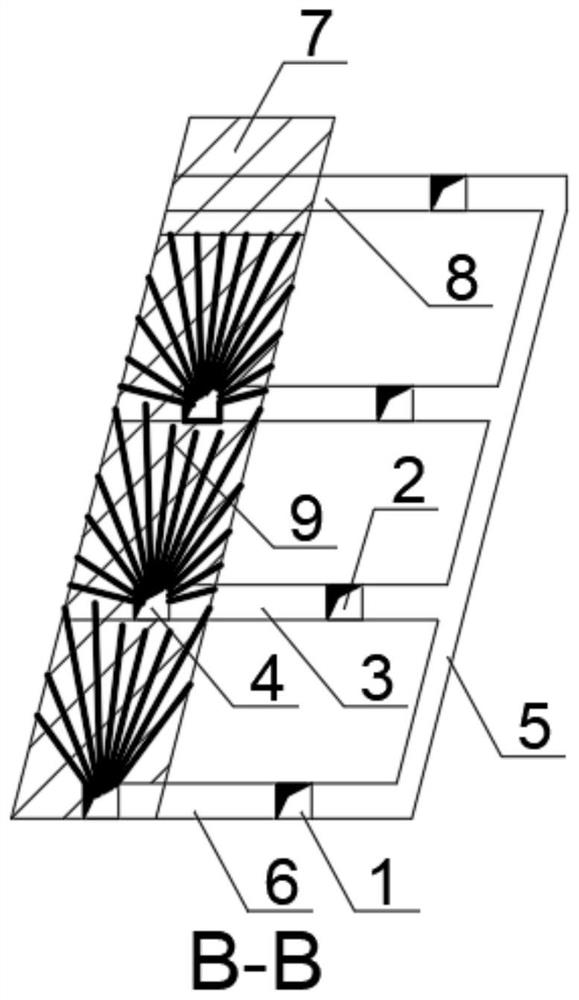

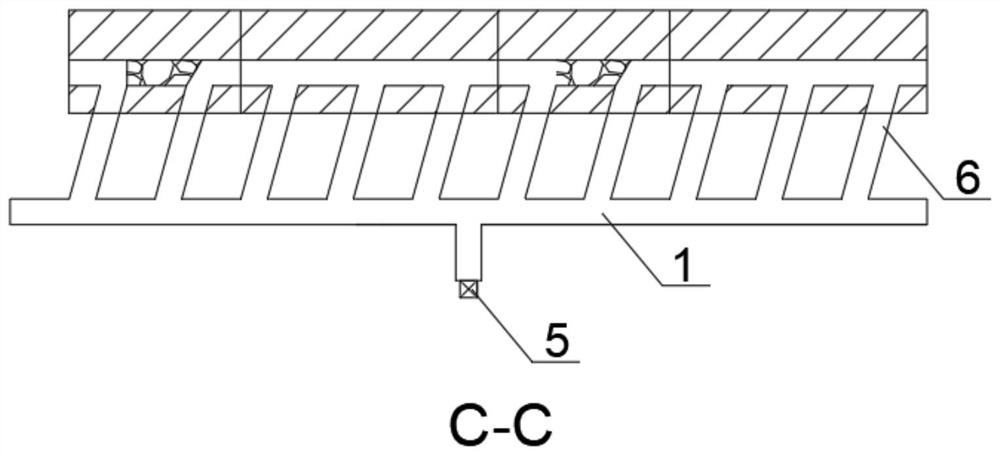

[0024] Such as Figure 1-Figure 3 As shown in the present invention, a V-shaped top pillar of medium-thick ore body provided by the present invention is drilled in stages and then filled. The mining blocks are arranged along the direction of the ore body, and the ore blocks are divided into a one-step stope and a two-step stope. , the length of the first-step stope along the strike is 15-20m, the length of the second-step stope along the strike is 30-50m, and the segment height is 12-25m....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap