Automatic die bonder for semiconductor chip processing

A technology of semiconductor and die bonding machine, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of cumbersome operation and uneven dispensing, and achieve the effect of ensuring quality, easy operation and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

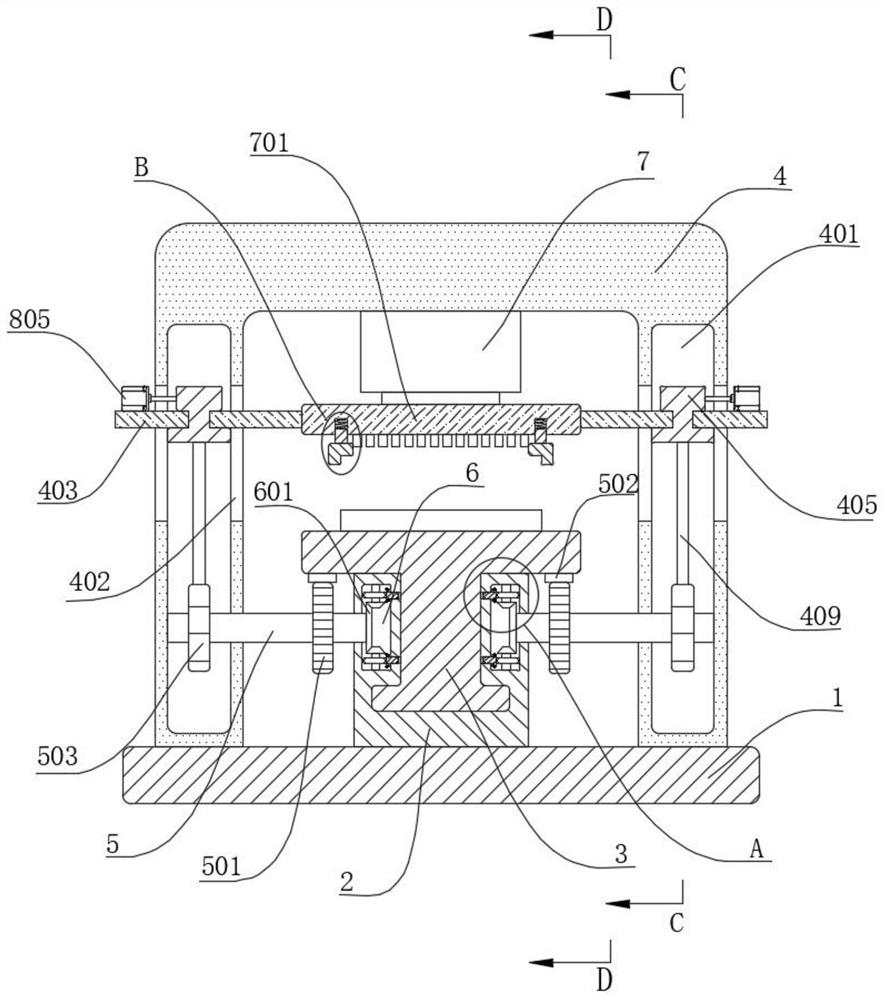

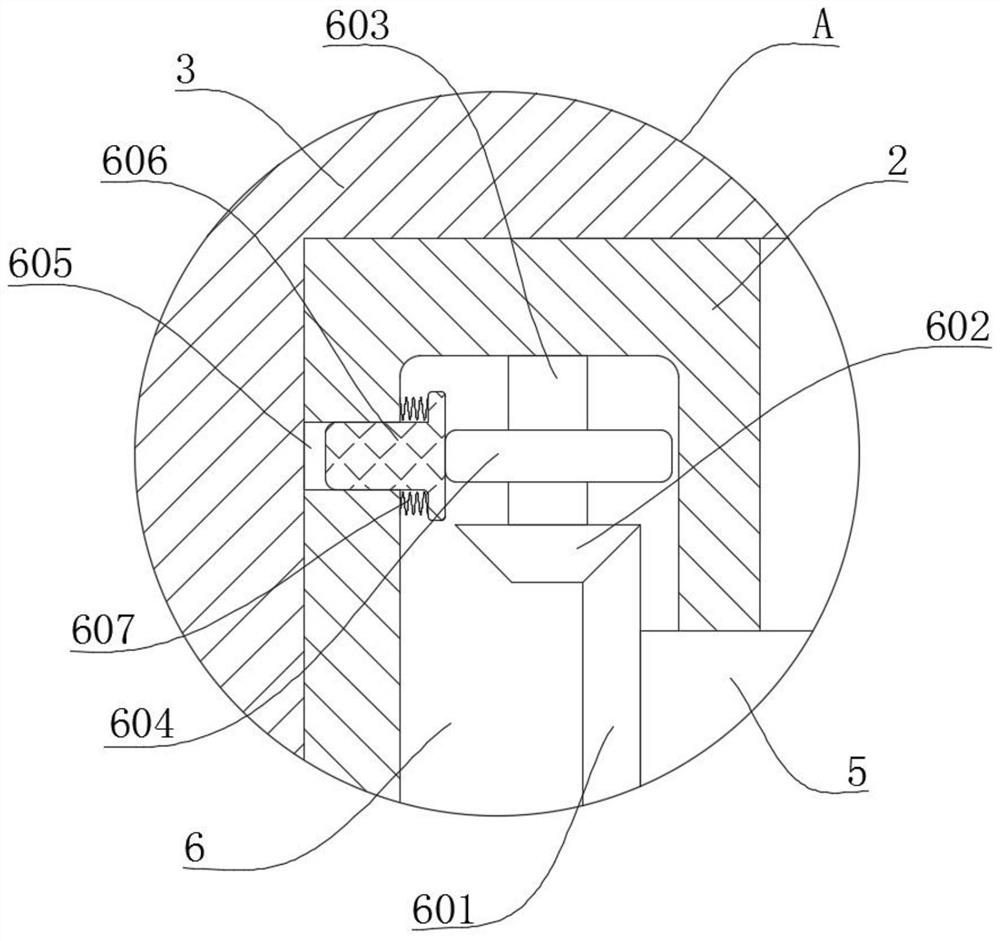

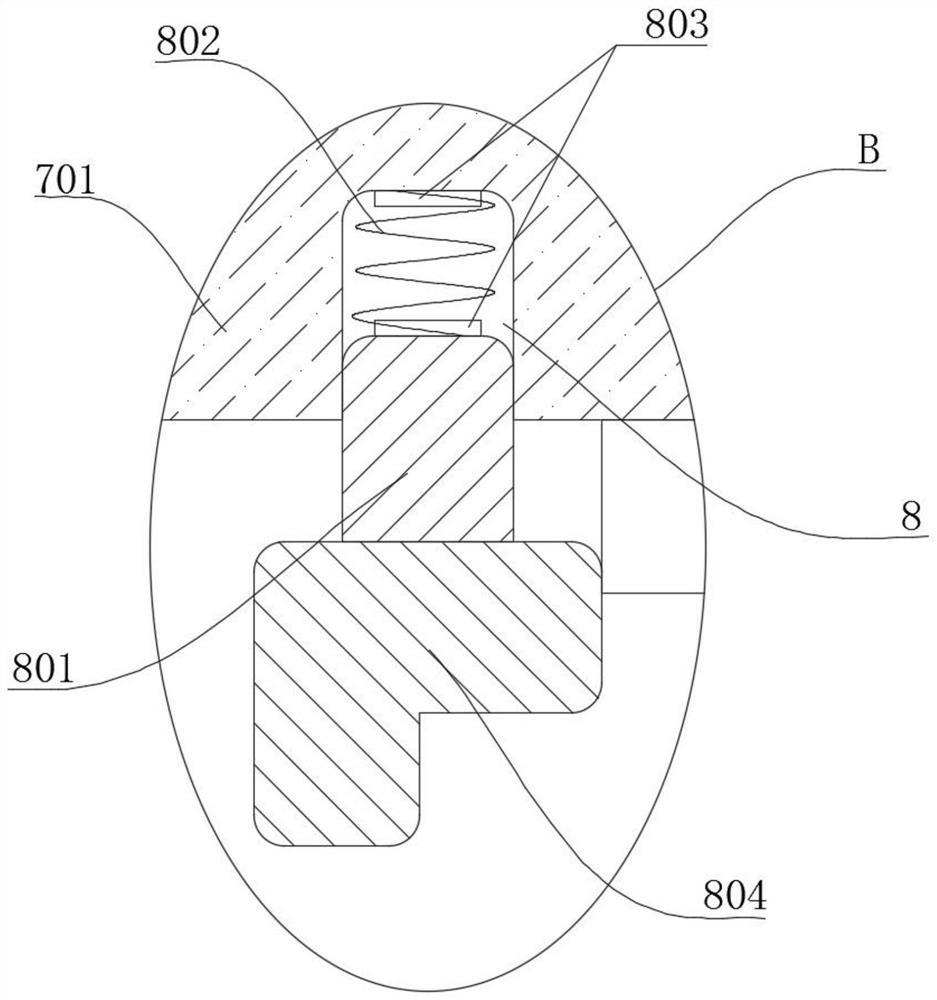

[0028] refer to Figure 1-8 , an automatic die bonding machine for semiconductor chip processing, including a base 1, the upper surface of the base 1 is fixedly connected with a slide rail 2, and the slide rail 2 is slidably connected with a sliding seat 3, such as figure 1 As shown, the cross-section of the sliding seat 3 is I-shaped, and the upper surface of the sliding seat 3 is provided with a chip tray, a processing tray, and a tin plastic tray, and its setting direction is as follows: figure 1 Arranged from right to left, the upper surface of base 1 is fixedly connected with U-shaped beam 4, the lower surface of U-shaped beam 4 is fixedly connected with electric push rod 7, the lower surface of the horizontal part of electric push rod 7 is fixedly connected with electric push rod 7, and the electric push rod 7 The output end of the rod 7 is fixedly connected with a vacuum block 701. A vacuum cavity is arranged in the vacuum block 701, and a vacuum suction head is provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap