Preparation method and application of an in-situ carbon-coated binary transition metal oxide heterojunction bowl-shaped nanocomposite

A nanocomposite material and transition metal technology, applied in nanotechnology, nanotechnology, active material electrodes, etc., can solve problems such as poor rate performance and short battery cycle life, and achieve reduced band gap, high repeatability, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

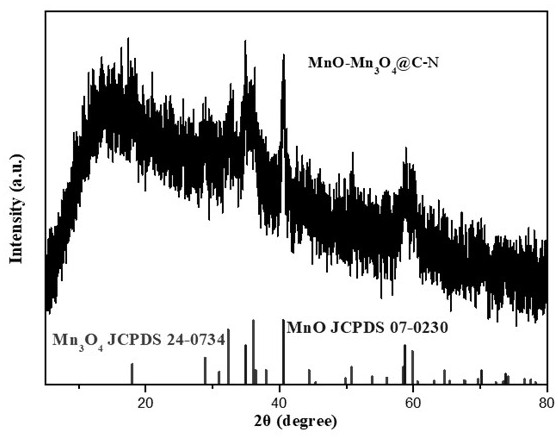

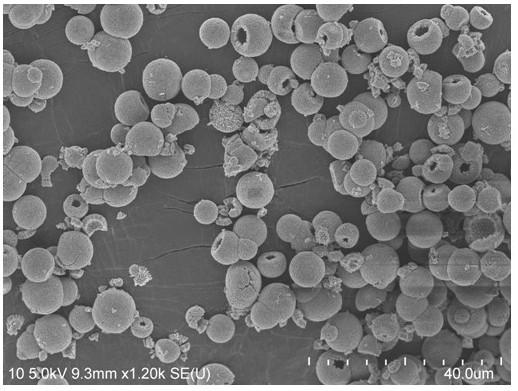

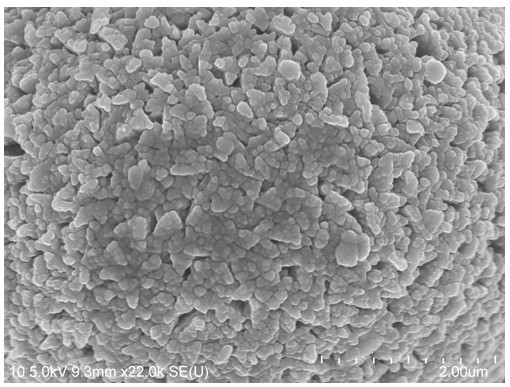

[0030] Preparation of MnO-Mn 3 o 4 @C-N nanocomposite material

[0031] Disperse 5.6g of polyvinylpyrrolidone in a mixed solution of 100mL of absolute ethanol and primary deionized water (volume ratio 2:1) and stir and mix evenly at 300rpm, then add 1.1g of manganese acetate tetrahydrate at the same speed And stir and mix uniformly to obtain a clear and transparent solution X; dissolve 2.0g of trimesic acid in a mixed solution of 100mL of absolute ethanol and primary deionized water (volume ratio 2:1) and stir and mix uniformly to obtain a solution Y, then at 300rpm Use BT100-2J peristaltic pump under the condition -1 The flow rate was added to the clear and transparent solution X obtained in step S1, and it was left to stand for several hours, and then the resulting precipitate was collected by centrifugation, and the resulting precipitate was washed with absolute ethanol several times to remove surfactants and residual ions, and then the resulting product was Dry in a vac...

Embodiment 2

[0033] Preparation of MnO-Mn 3 o 4 @C-N nanocomposite material

[0034] Disperse 6.1g of polyvinylpyrrolidone in a mixed solution of 120mL of absolute ethanol and primary deionized water (volume ratio 2:1) and stir and mix evenly at 350rpm, then add 1.6g of manganese acetate tetrahydrate at the same speed And stir and mix uniformly to obtain a clear and transparent solution X; dissolve 2.8g of trimesic acid in a mixed solution of 100mL absolute ethanol and primary deionized water (volume ratio 2:1) and stir and mix uniformly to obtain a solution Y, then at 350rpm Use BT100-2J peristaltic pump under the condition -1 The flow rate was added to the clear and transparent solution X obtained in step S1, and it was left to stand for several hours, and then the resulting precipitate was collected by centrifugation, and the resulting precipitate was washed with absolute ethanol several times to remove surfactants and residual ions, and then the resulting product was Dry in a vacuum...

Embodiment 3

[0036] Preparation of MnO-Mn 3 o 4 @C-N nanocomposite material

[0037] Disperse 6.8g of polyvinylpyrrolidone in a mixed solution of 180mL of absolute ethanol and primary deionized water (volume ratio 2:1) and stir and mix evenly at 410rpm, then add 2.3g of manganese acetate tetrahydrate at the same speed And stir and mix uniformly to obtain a clear and transparent solution X; dissolve 3.2g of trimesic acid in a mixed solution of 180mL absolute ethanol and primary deionized water (volume ratio 2:1) and stir and mix uniformly to obtain a solution Y, then at 410rpm Use BT100-2J peristaltic pump under the condition -1 The flow rate was added to the clear and transparent solution X obtained in step S1, and it was left to stand for several hours, and then the resulting precipitate was collected by centrifugation, and the resulting precipitate was washed with absolute ethanol several times to remove surfactants and residual ions, and then the resulting product was Dry in a vacuum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap