Glasses caring and storage device with automatic cleaning function

A storage device and automatic cleaning technology, applied in glasses/goggles, glasses/safety glasses, measuring devices, etc., can solve the problems of the overall weight of the glasses case becoming larger and inconvenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

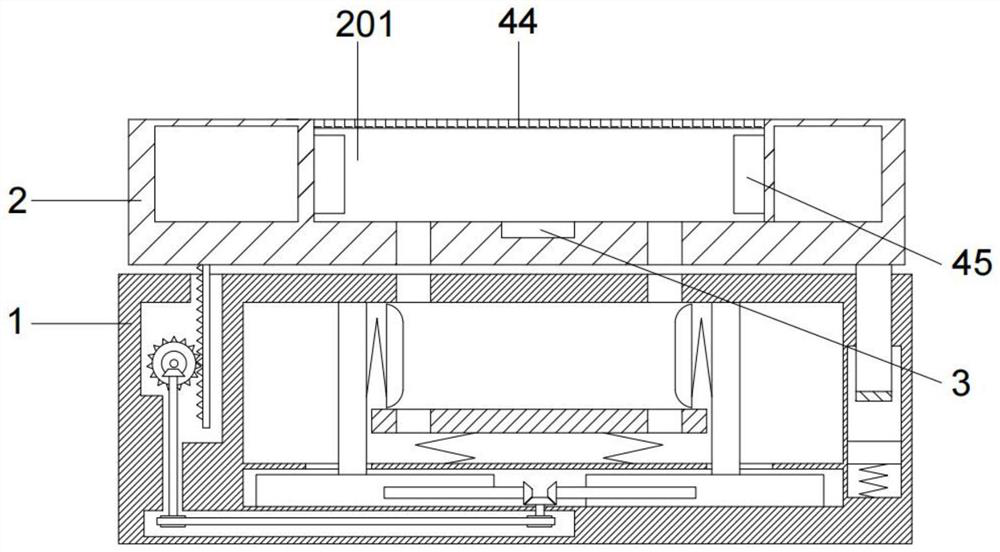

[0056] Embodiments of the present invention provide a glasses care storage device with automatic cleaning function, such as Figure 1-Figure 2 As shown, it includes a box body 1 and a cleaning shell 2. The box body 1 and the cleaning shell 2 are detachably connected through a connecting mechanism 1 and a connecting mechanism 2. The box body 1 is provided with a storage bin 101 and a driving mechanism. A protection mechanism is provided inside the storage compartment 101, and the drive mechanism is connected with the protection mechanism. A cleaning compartment 201 is provided inside the cleaning shell 2, and a cover plate 44 is provided on the upper end of the cleaning compartment 201. The left and right sides of the cleaning compartment 201 An ultrasonic cleaner 3 and a UV sterilization module 45 are arranged symmetrically on both sides;

[0057] The cleaning chamber 201 is an ultrasonic cleaning tank, the UV sterilization module 45 is arranged at the side end of the cleaning...

Embodiment 2

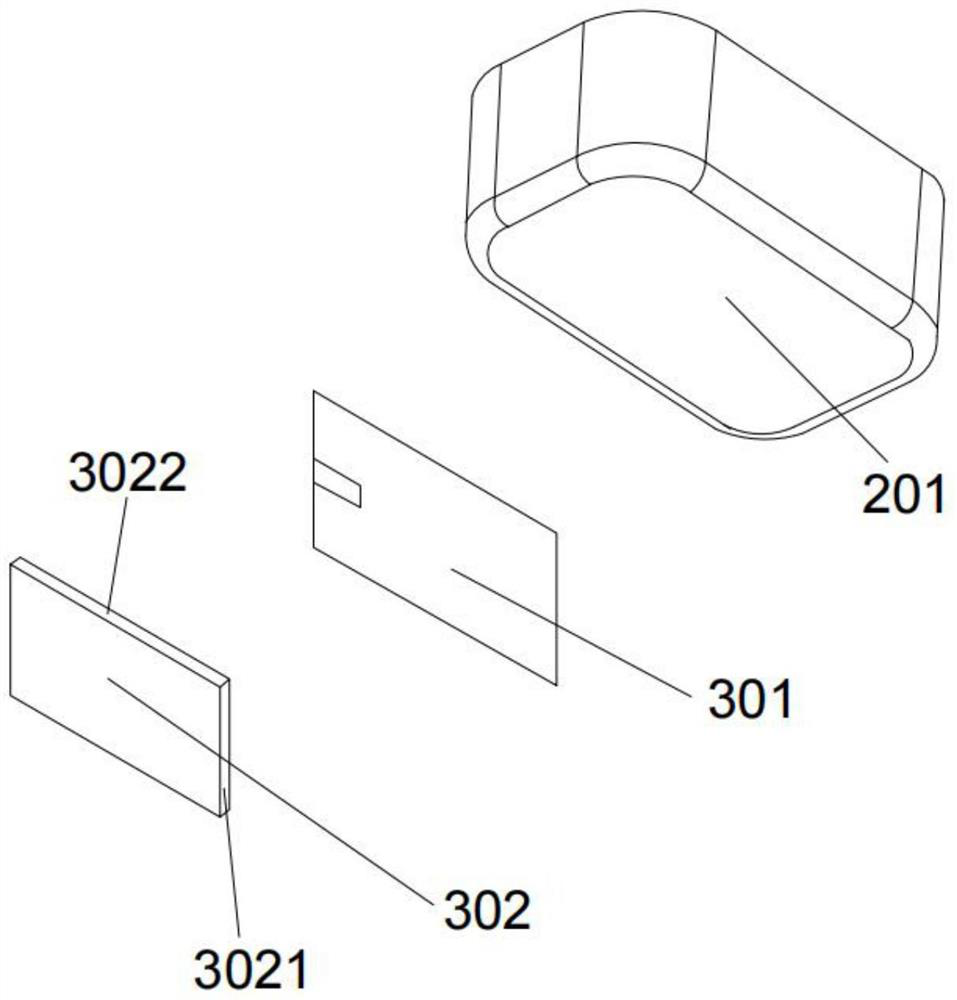

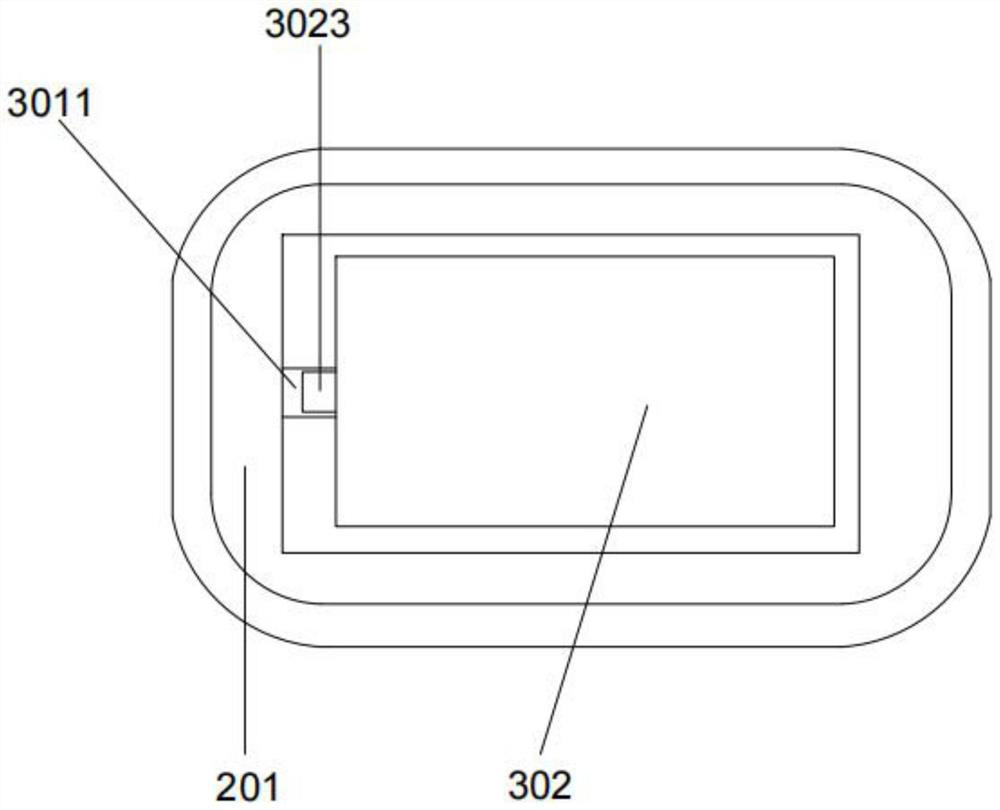

[0061] On the basis of Example 1, such as Figure 2-Figure 3As shown, the piezoelectric ceramic sheet 302 includes a rectangle or a circle, the piezoelectric ceramic sheet 302 is preferably rectangular and the piezoelectric ceramic sheet 302 is a rectangle, then the ceramic sheet includes a length portion 3022 for controlling the output frequency and a Change the width portion 3021 of the power capacity, the length dimension of the length portion 3022 is not less than 1 / 2 of the length dimension of the cleaning chamber 201, and the insulation sheet 301 is an insulating material such as bakelite board or fiberglass board, which is in the shape of a pressure Electric ceramic sheet 302 is a rectangle with the same length and width. The ultrasonic generator module is a switching power supply of a self-excited or other-excited circuit, which can automatically obtain the best operating frequency of the cleaning equipment to drive the piezoelectric ceramic 302 to work. The ultrasonic...

Embodiment 3

[0065] On the basis of Example 1, such as Figure 4 As shown, the right side of the upper end of the box body 1 is provided with a connecting hole 2 104, and the lower end of the connecting hole 104 is connected with a connecting hole 103, and the connecting hole 103 is provided with the connecting mechanism 1 inside. , the connecting mechanism one includes a spring one 403, the spring one 403 is fixedly arranged at the bottom end of the connecting hole one 103, the spring one 403 is fixedly connected with the magnetic block one 402, and the magnetic block one 402 is slidably set Between the left and right ends of the first connecting hole 103;

[0066] The second connecting mechanism includes a connecting block 4 fixedly connected to the right side of the lower end of the cleaning shell 2, the connecting block 4 can be slidably connected to the second connecting hole 104, and the lower end of the connecting block 4 is fixedly connected with a magnetic block Two 401 , the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com