Cylindrical town sewage treatment equipment

A technology of urban sewage and treatment equipment, which is applied in the field of urban sewage treatment and resource utilization, and can solve the problem of decreased permeability of the filter layer to sewage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

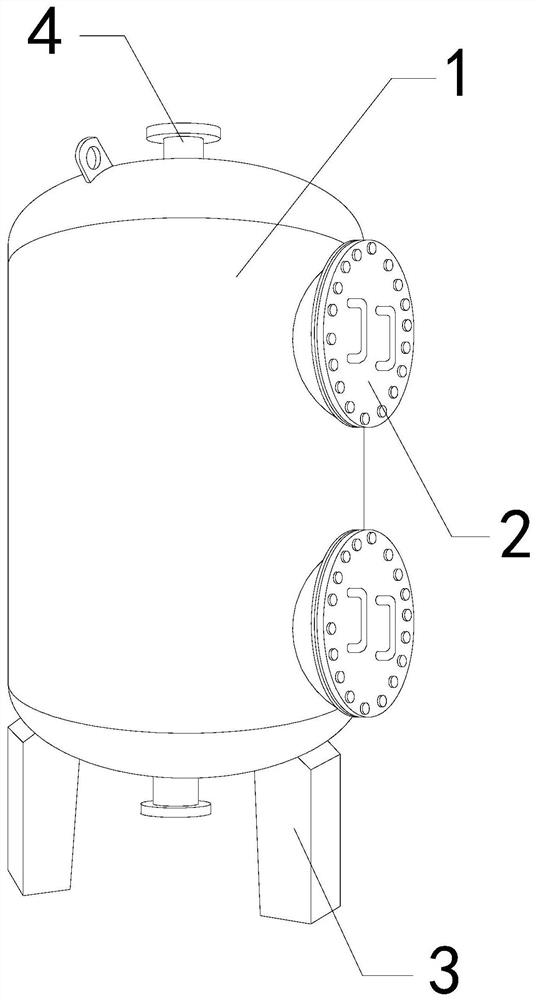

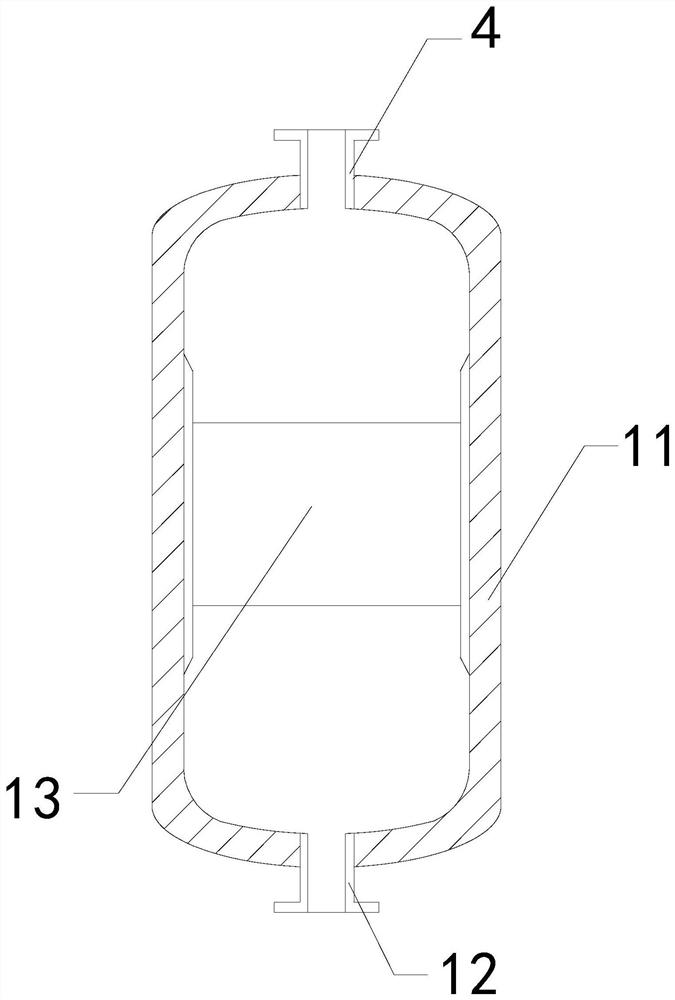

[0028] For example figure 1 -example Figure 5 Shown:

[0029] The invention provides a cylindrical urban sewage treatment equipment, the structure of which includes a tank body 1, an observation port 2, a base bracket 3, and a sewage inlet 4. The observation port 2 is installed on the side of the tank body 1, and the The sewage inlet 4 is embedded in the upper end of the tank body 1, and the bottom of the tank body 1 is welded to the upper end of the base bracket 3; The drain port 12 is fixed at the lower end of the outer frame 11 , and the filter layer 13 is fixed between the inner walls of the outer frame 11 .

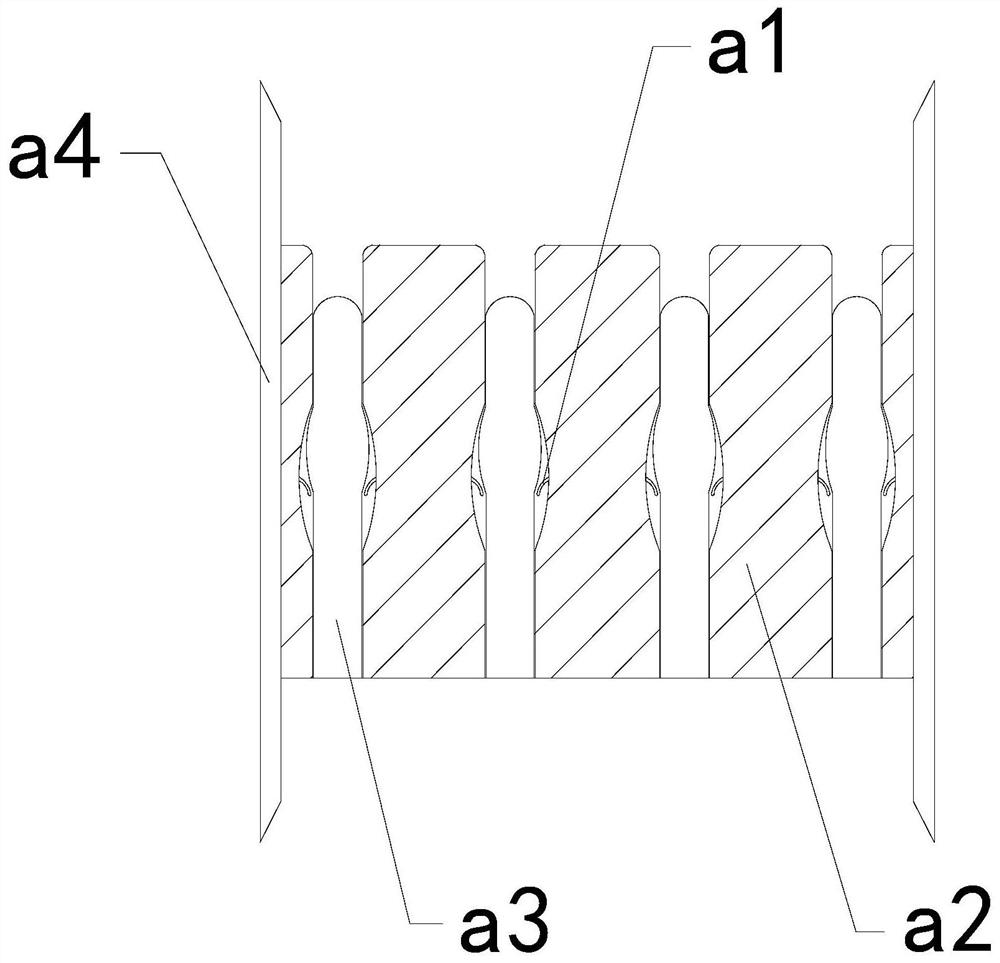

[0030] Wherein, the filter layer 13 includes a rebound piece a1, a purification block a2, a sliding bar a3, and an connecting plate a4, the rebounding piece a1 is connected to the inner wall of the purification block a2, and the purification block a2 is installed on two connecting plates a4 Between the inner sides of the sliding rod a3 and the inside of the rebou...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037]Wherein, the bearing block b3 includes an external frame b31, a bottom slide b32, a rebound bar b33, and a linkage block b34, the upper end of the bottom slide b32 is connected to the bottom of the linkage block b34, and the rebound bar b33 is installed on the linkage block Between b34 and the inner wall of the outer frame b31, the linkage block b34 is slidingly fitted with the inner side of the outer frame b31, and there are two linkage blocks b34, which are evenly symmetrical on the inner walls of the left and right sides of the outer frame b31 Distribution, through the inertial force generated by the mechanism sliding downwards and protruding, the bottom sliding plate b32 can slide and protrude downwards along the outer frame b31 under the cooperation of the linkage block b34, so that the bottom sliding plate b32 can shake off part of the moss.

[0038] Wherein, the bottom sliding plate b32 includes a top plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com