Equipment for guaranteeing dimensional precision of forged and pressed part

A dimensional accuracy and forging technology, which is applied in the field of equipment to ensure the dimensional accuracy of forged parts, can solve the problems of reducing the diameter of the feeding port and reducing the effect of introducing molten raw materials, and achieves the effect of avoiding difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

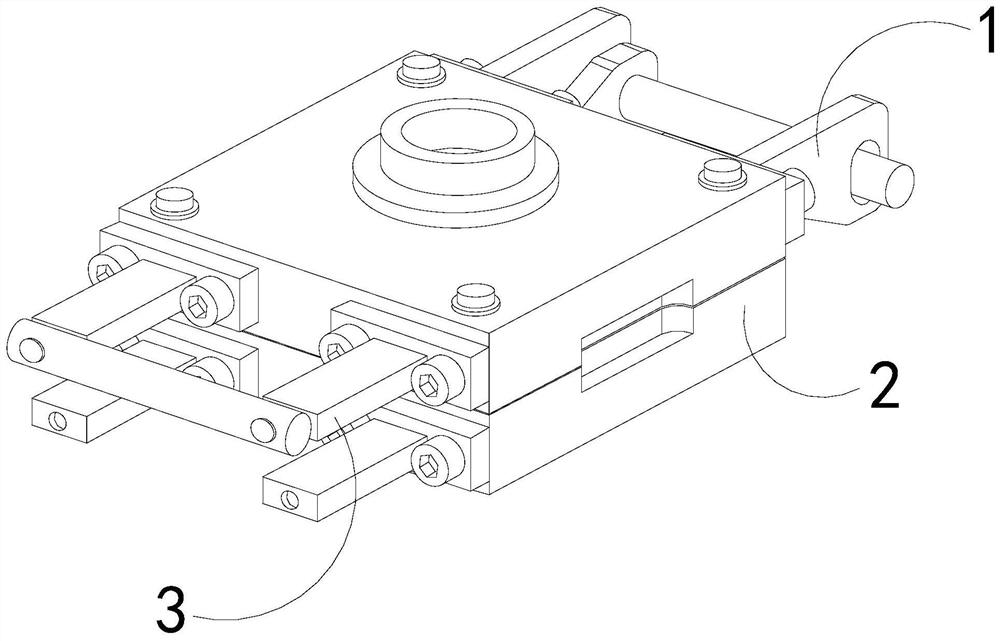

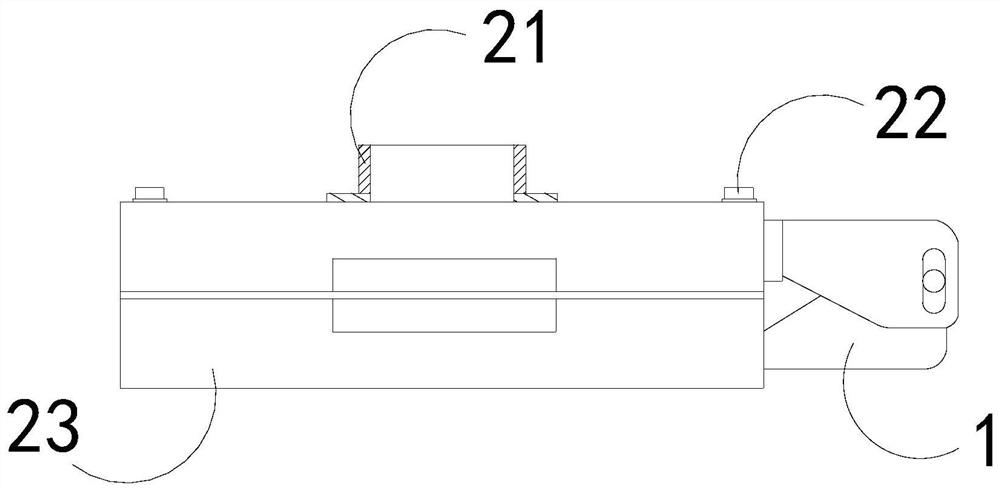

[0028] For example figure 1 -example Figure 5 Shown:

[0029] The invention provides a device for ensuring the dimensional accuracy of forging parts. Its structure includes a hinge frame 1, a forging mechanism 2, and a handle 3. The handle 3 is screwed to the front end of the forging mechanism 2. The rear end of the forging mechanism 2 is connected to the The front end of the frame 1 is welded; the forging mechanism 2 includes a feed port 21, a fixing bolt 22, and a mold 23, the feed inlet 21 is fixed on the top of the mold 23, and the fixing bolt 22 is threaded with the mold 23.

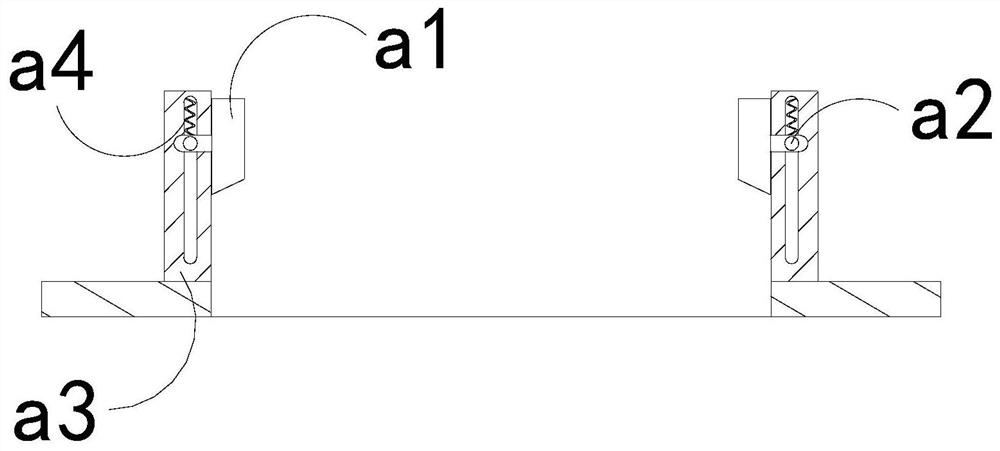

[0030] Wherein, the feed port 21 includes a lower plate a1, a linkage rod a2, an engaging frame a3, and an elastic bar a4, the lower plate a1 is attached to the outer end of the linkage rod a2, and the linkage rod a2 is connected to the retaining rod a2. The internal movable engagement of the frame a3, the elastic bar a4 is installed between the upper end of the inner wall of the retaining frame ...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037]Wherein, the lower fixing plate a13 includes a movable wheel c1, a receiving plate c2, and a vibrating block c3, the movable wheel c1 is movably engaged with the right side of the receiving plate c2, and the vibrating block c3 is installed in the inner position of the receiving plate c2 , the movable wheel c1 is provided with four, and evenly distributed in parallel on the right side of the receiving plate c2, through the thrust generated by the molten raw material on the movable wheel c1, the movable wheel c1 can be rotated along the receiving plate c2, and Through the inertial force generated by the reset of the mechanism, the vibrating mass c3 can generate impact vibration against the inside of the receiving plate c2.

[0038] Wherein, the movable wheel c1 includes a center block c11, an elastic ring c12, and a contact plate c13, the elastic ring c12 is fixed on the outer side of the center block c11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com