Uniform-mixing tobacco shred mixing device and mixing method

A technology of uniform mixing and mixing device, applied in the directions of mixing methods, mixers, chemical instruments and methods, etc., can solve the problems of damaged tobacco structure, insufficient cigarette quality, complicated steps, etc., and achieves high mixing uniformity, cigarette quality assurance, High mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

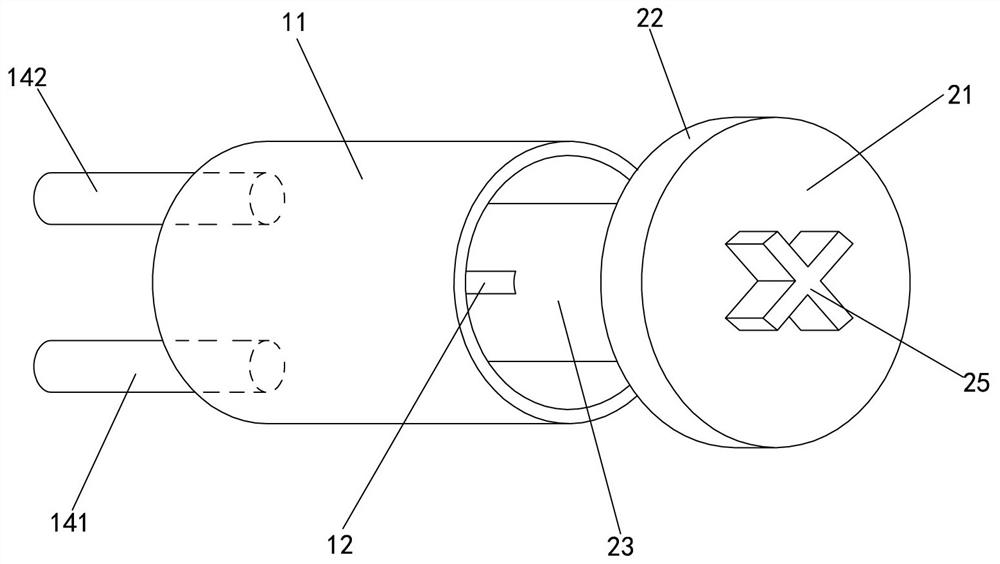

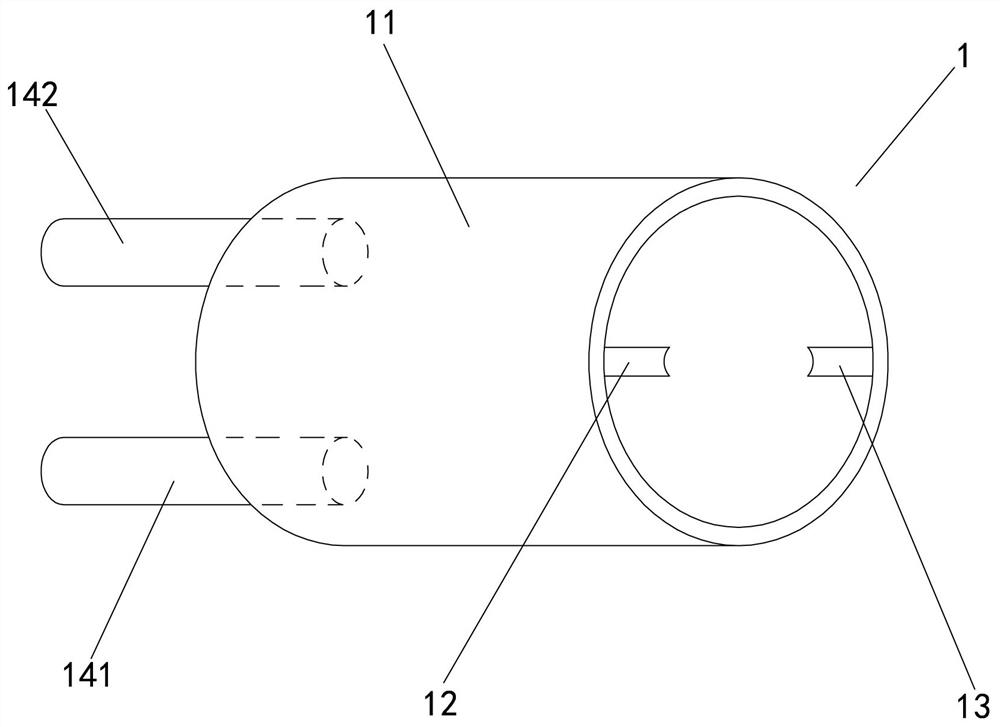

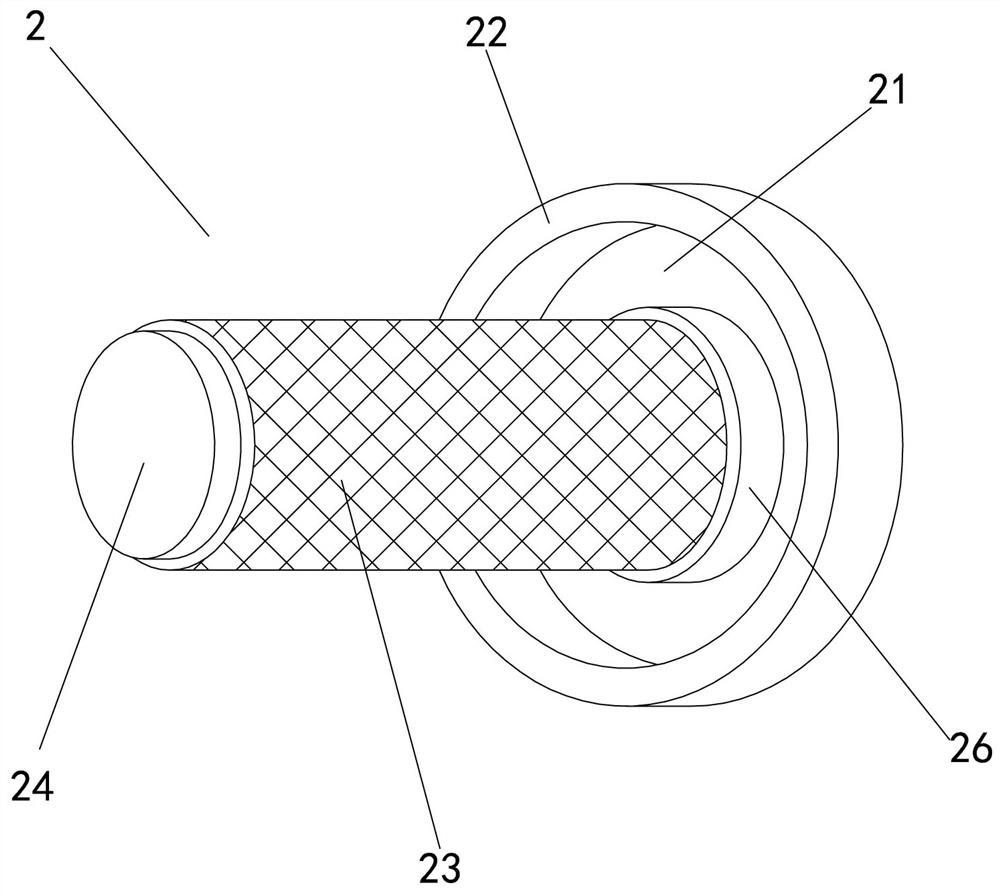

[0039] Embodiment one: if Figures 1 to 5 As shown, it is only one of the embodiments of the present invention, a homogeneously mixed shredded tobacco mixing device, including a blower part 1 and a loading part 2, and the blower part 1 includes a blower tube 11, which is arranged on the blower The first limiting plate 12 on the inner wall of the blower 11 and the second limiting plate 13 arranged on the inner wall of the blower 11 away from the first limiting plate 12, the blower 11 A bottom plate 14 is provided on the side away from the loading portion 2, and the bottom plate 14 is provided with an air inlet pipe 141 located on the lower side of the connecting line between the first limiting plate 12 and the second limiting plate 13 and located on the bottom of the connecting line. The air outlet pipe 142 on the upper side of the connecting line between the first limiting plate 12 and the second limiting plate 13, the loading part 2 includes a loading plate 21, and the loadin...

Embodiment 2

[0047] Embodiment two, still as Figures 1 to 5 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a uniformly mixed shredded tobacco mixing device of the present invention, the first limiting plate 12 is close to the second limiting plate 13 One end of the second limit plate 13 is provided with a first arc surface for cooperating with the outer arc surface of the loading cylinder 23, and one end of the second limit plate 13 close to the first limit plate 12 is provided with a The second arc of the arc mate. In fact, the curved radians of the first arc surface and the second arc surface are equal to the curvature arc of the outer wall of the loading cylinder 23, and the farthest distance between the first arc surface and the second arc surface is just equal to that of the loading cylinder 23. outer diameter, so that the loading cylinder 23 can be seamlessly inserted between the first limiting plate 12 and the second limiting...

Embodiment 3

[0054] Embodiment three, such as Figure 6 As shown, the present invention also provides a mixing method of a homogeneously mixed shredded tobacco mixing device in all above-mentioned embodiments, comprising the following steps:

[0055] S1: Open the cover plate of the loading tube, place all kinds of shredded tobacco in the loading tube according to the predetermined amount, and cover the cover plate;

[0056] S2: Displacing the loading part, inserting the loading tube into the blower tube of the blowing part, so that the loading tube is stuck between the first limiting plate and the second limiting plate;

[0057] S3: Continue to displace the loading part until the entire loading tube is fully inserted into the blower of the blower part, so that the outer ring is placed outside the end of the blower away from the bottom plate;

[0058] S4: Start the blower connected to the air inlet pipe, and the blown air flows into the blower through the air inlet pipe, and passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com