Tool equipment for hanging bracket welding and hanging bracket welding method

A tooling equipment and hanger technology, applied in the field of hanger welding tooling equipment and hanger welding, can solve the problem of lack of reference materials, and achieve the effects of ensuring coaxiality, improving welding efficiency, and fast welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

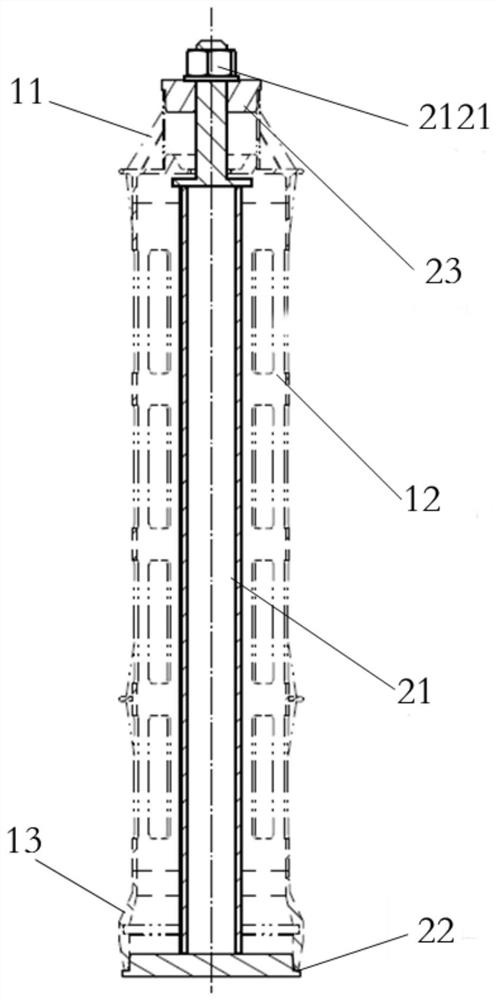

[0030] In order that those skilled in the art better understand the solutions of the present application, the present application the following described in further detail in conjunction with accompanying drawings and specific embodiments.

[0031] Is to be understood that the use of "first," "second," "third," etc. defined components is only for convenience to distinguish the above-described components, if not stated otherwise, the words above and no special meaning, It can not be construed as limiting the scope of protection of the present application. In the description of the present application, the meaning of "multiple" is at least two, such as two, three, etc., unless otherwise specifically defined.

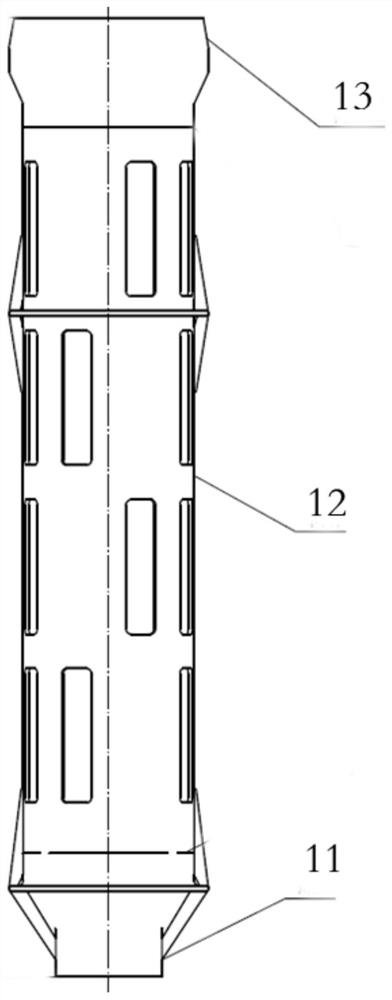

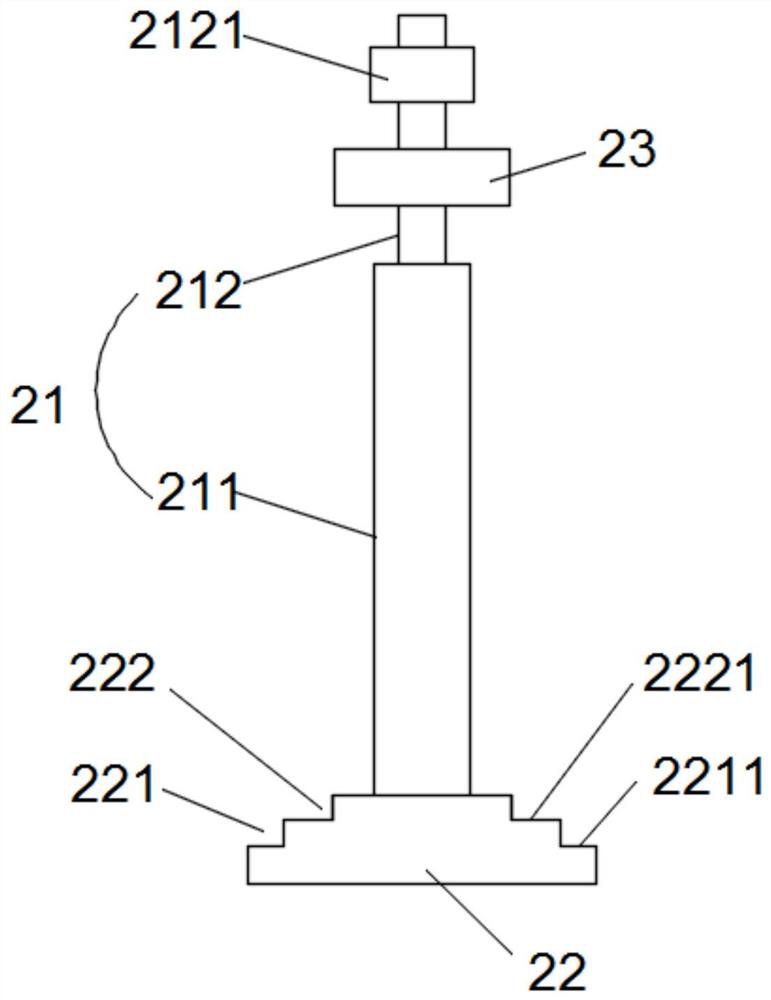

[0032] refer to figure 1 Hanger according to this embodiment, may include a cradle include a base 11 connected sequentially, the barrel 12 and barrel flange 13, the base 11 is provided with a through hole 12 in the axial direction of the cylinder. Wherein the hanger is mainly ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap