A device for eliminating the weld gap between the tank body and the annular rib plate

A ring-shaped, ribbed technology, applied in the field of devices for eliminating the weld gap between the tank body and the ring-shaped ribbed plate, can solve the problems of uneven force on the ring-shaped ribbed plate, uneven manpower, unstable welding quality, etc., and achieve Ensure the integrity of the appearance, improve the automation level, and improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below according to the accompanying drawings and embodiments.

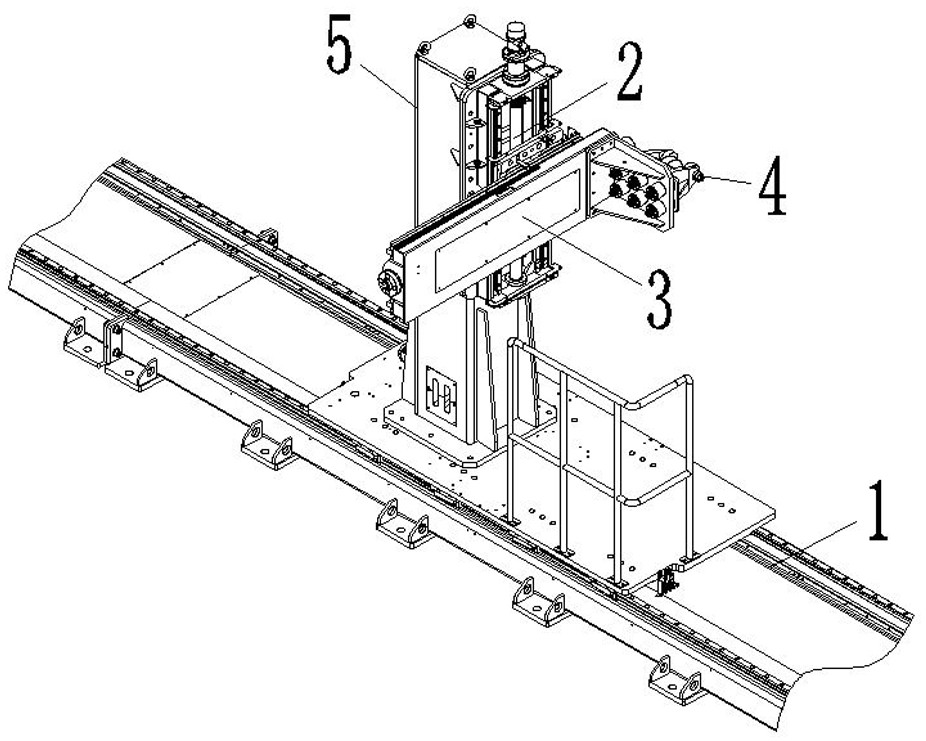

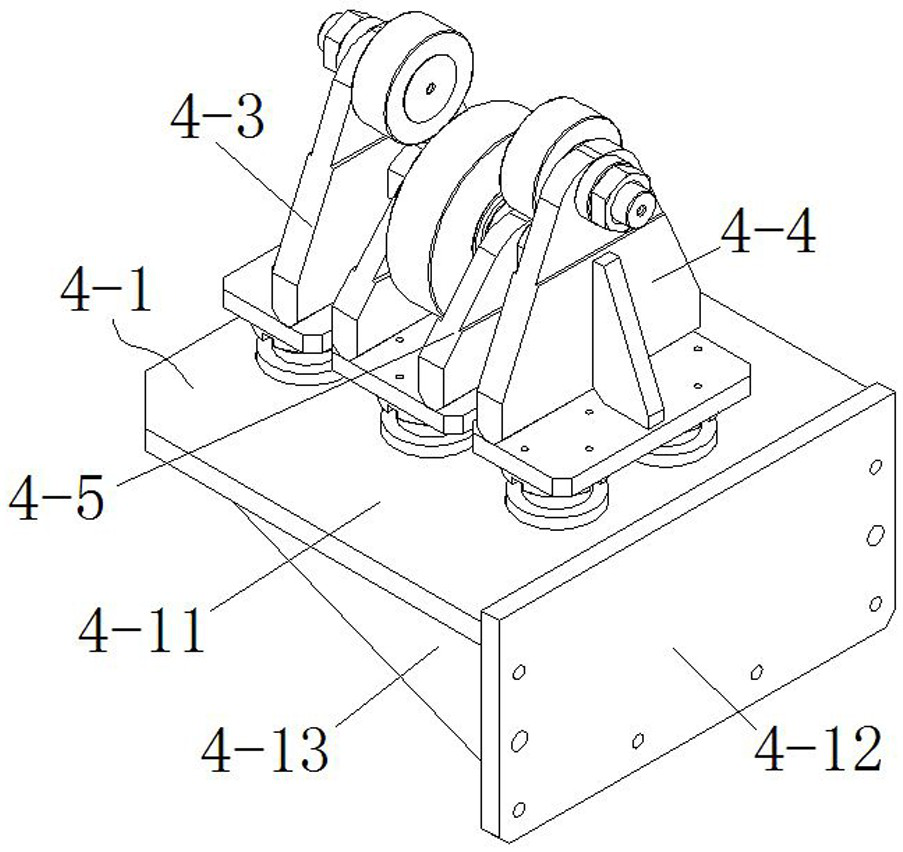

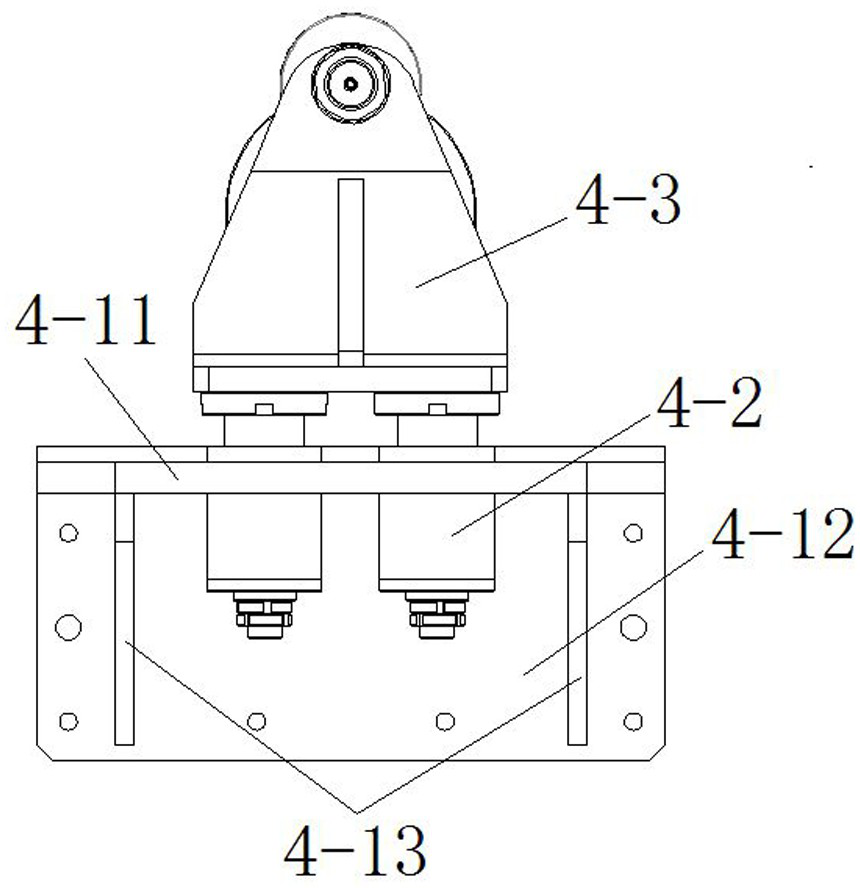

[0027] Such as figure 1 As shown, a device for eliminating the weld gap between the tank body and the annular rib plate includes a position moving device 1 in the X direction, a vertical lifting device 2 in the Z direction, a horizontal advance and retreat device 3 in the Y direction, and a pressing wheel device 4 .

[0028] Among them, such as Figure 5 As shown, the X-direction position moving device 1 includes a moving ground rail assembly 1-1, a moving slide plate assembly 1-2, a moving drive assembly 1-3 and a position moving guide rail slider assembly 1-4. The position moving guide rail slider assembly 1-4 includes a guide rail and a slide block, and two guide rails are arranged in parallel on the mobile ground rail assembly 1-1, and each guide rail is provided with a plurality of slide blocks. The sliding block of the mobile slide assembly 1-2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com