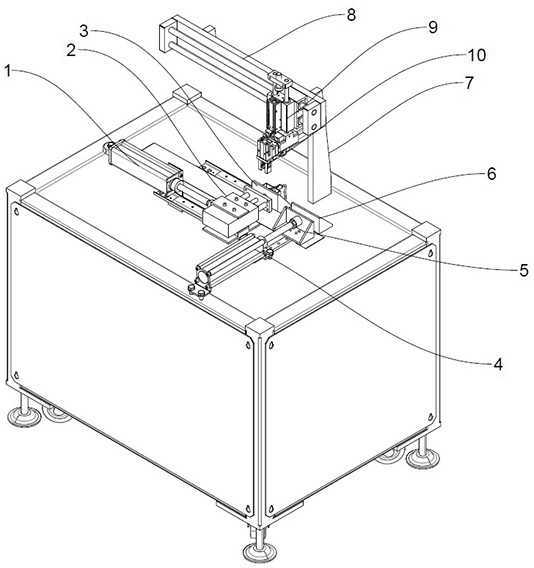

Special-shaped steel pipe welding device

A technology for welding devices and special-shaped steel pipes, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as inappropriateness, and achieve the effect of improving clamping effect and precise clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

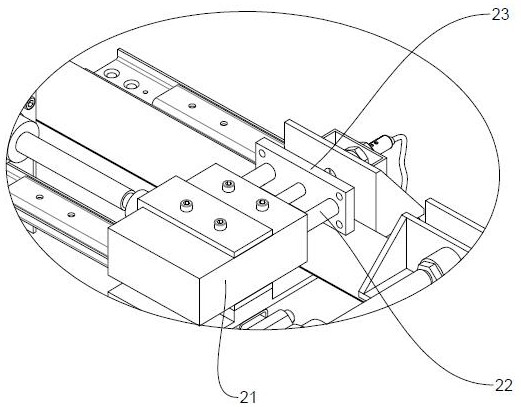

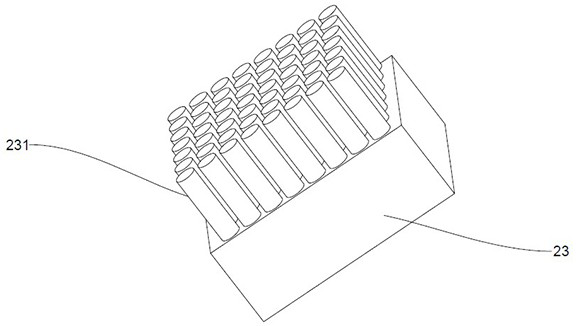

Method used

Image

Examples

Embodiment Construction

[0023] In order to solve the problems existing in the prior art, the applicant conducted an in-depth analysis on various existing solutions, as follows:

[0024] In some cases, two steel pipes need to be welded before they can be used. In order to align the welding joints of the two steel pipes, engineers have designed a variety of steel pipe welding and clamping equipment. For example, the publication number is CN111761289A, which discloses a clamping device for welding steel pipes. Two steel pipes to be welded are put into the clamping pipe, and the two steel pipes are clamped by adjusting four adjusting screws. This device has the following disadvantages:

[0025] First of all, due to the clamping method, the size of the clamping tube has a certain limit on the size of the steel pipe to be welded. If the size of the clamping tube exceeds the size of the clamping tube, it cannot be clamped; secondly, the adjusting screw is set in the clamping tube, which occupies a certain e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com