Star wheel accelerating device and star wheel vehicle

A technology of acceleration device and star-wheel vehicle, which is applied in the direction of wheel transmission, chain/belt transmission, vehicle parts, etc., can solve the problems of complex structure, difficult maintenance, high cost, etc., achieve wide application value and improve riding Speed, the effect of apparent technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

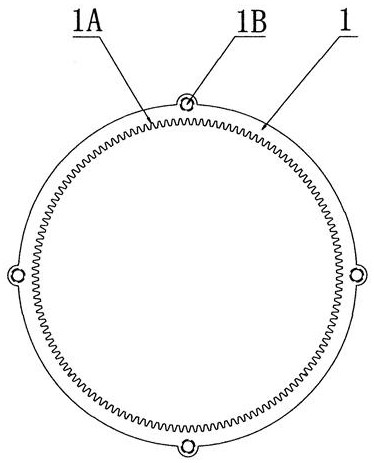

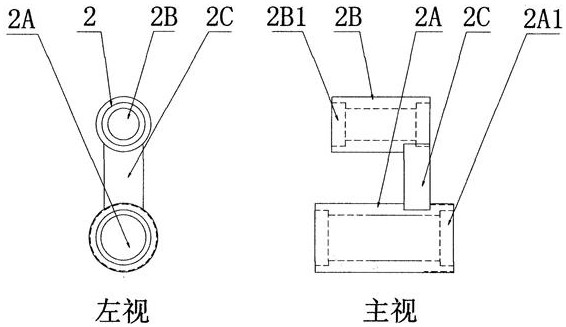

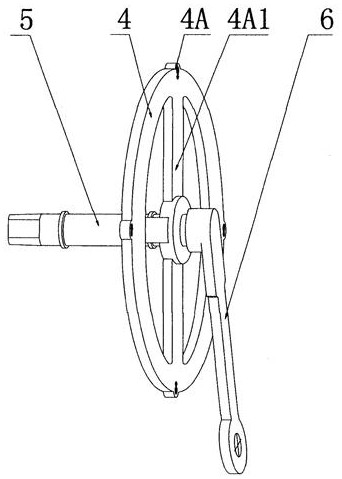

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the star wheel acceleration device T is composed of an inner ring gear wheel P, a pair of five-way star wheel frame 2 and a 16-teeth coaxial drive wheel 7 with a pitch of 12.7, wherein the inner ring gear wheel P has two types Structural methods, one is integral type, the other is split type; the center of the five-way star wheel frame 2 is the five-way 2A, and three cantilever 2C with an angle of 120 degrees is welded on the five-way 2A. The top of 2C welds three same Xingtong 2B, each Xingtong 2B is equipped with a bearing seat 2B1 like the bottom bracket 2A, and the axes of the three bearing seats 2B1 are on the same circle centered on the bottom bracket bearing seat 2A1 above; install three identical star wheels 3 on Xingtong 2B, and install the coaxial drive wheel 7 on the star wheel shaft protruding from the other end of one of Xingtong 2B; install the inner ring gear disc P on On the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com