Spraying dustproof equipment for dumper and using method thereof

A technology of dust-proof equipment and dump trucks, applied in the direction of separation methods, using liquid separation agents, chemical instruments and methods, etc., can solve the problems of air pollution, dirty urban roads, cumbersome operation steps, etc., and achieve small application range and convenience Atomization dust reduction, flexible overall design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

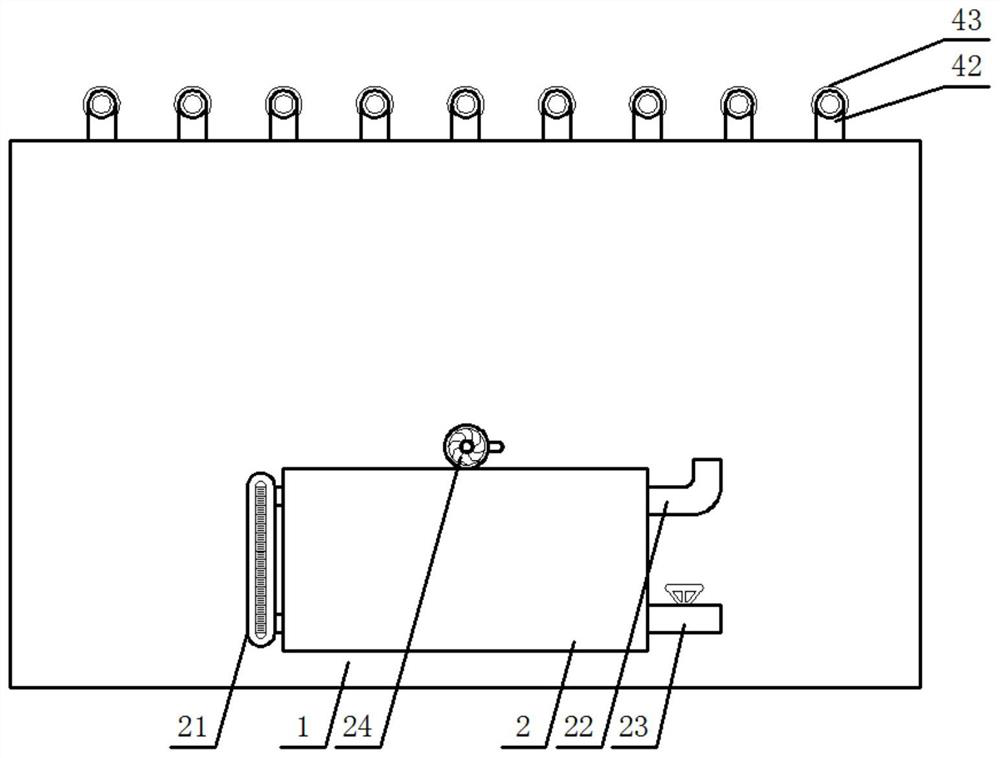

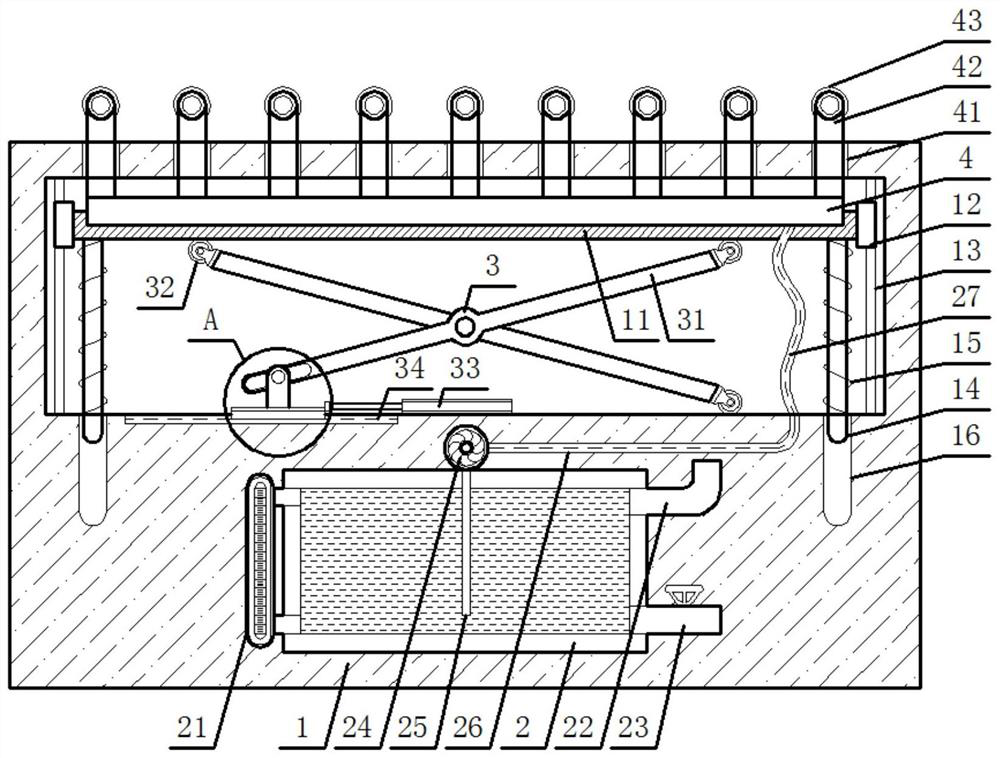

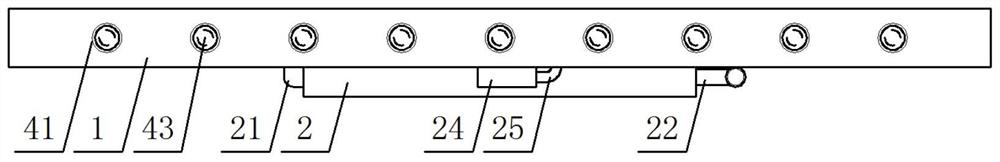

[0032] Embodiment 1: In order to solve the problem of inconvenient spray dust removal, a kind of spray dust prevention equipment for dump trucks is proposed in this embodiment, see Figure 1-4 , including a side plate 1, a hinge mechanism, and a water pump mechanism, the side plate 1 is a rectangular plate placed horizontally and horizontally, a rectangular cavity is opened on the inner top of the side plate 1, and a support plate placed horizontally is provided in the rectangular cavity 11. The bottom surface of the support plate 11 is connected to the rectangular chamber through a hinge mechanism, and the top surface of the support plate 11 is provided with a horizontally fixed spray tube 4; the front bottom of the side plate 1 is provided with a horizontally fixed The water tank 2 communicates with the spray horizontal pipe 4 through a water pump mechanism.

[0033] In the present invention, a pair of vertically symmetrically fixed T-shaped slide rails 13 are provided on bo...

Embodiment 2

[0039] Example 2: see Figure 5 , in the present embodiment, the present invention also proposes a method for using the spray dust-proof equipment for dump trucks, comprising the following steps:

[0040] Step 1, the side plate 1 is a side compartment of the dump truck, the high-pressure water pump 24 and the telescopic cylinder 33 are respectively electrically connected to the vehicle power supply through the power line, the drain valve is closed, and the water volume is replenished to the water tank 2 through the L-shaped water injection pipe 22, and the water is passed through the liquid The position pipe 21 observes the amount of water in the water tank 2; under normal circumstances, the fine spray tube 42 and the atomizing nozzle 43 are located in the through hole 41 and are not exposed, so as to prevent the atomizing nozzle 43 from interfering with the normal operation of the dump truck and prevent The atomizing nozzle 43 was damaged;

[0041] Step 2: When spraying and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com