Lightweight high-strength gypsum plaster board and preparation method thereof

A kind of gypsum board, high-strength technology, used in construction, building structure, covering/lining, etc., can solve the problem of difficult removal, and achieve the effect of inhibiting migration, good bonding performance and low areal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

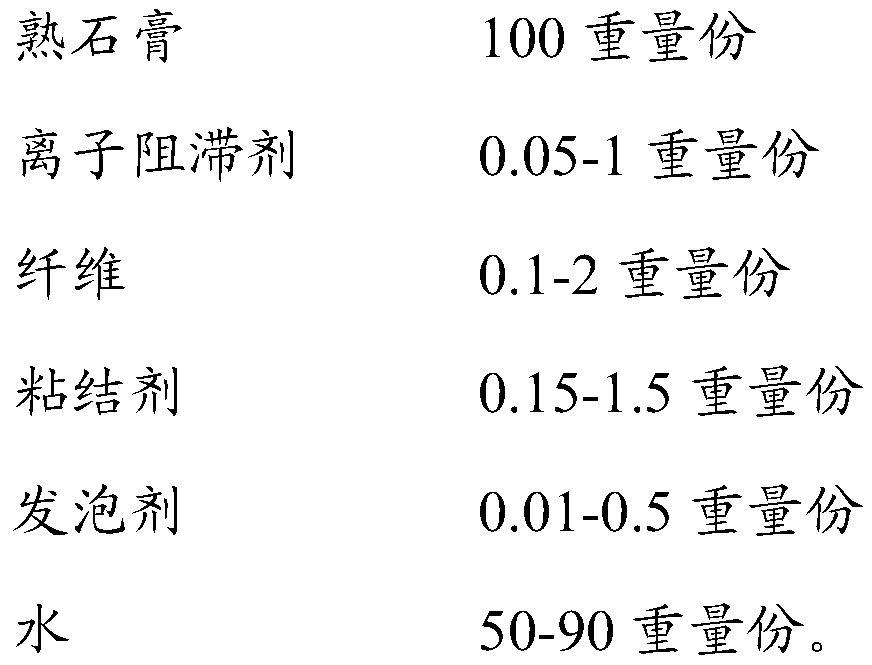

[0034] The embodiment of the present application provides a light-weight high-strength gypsum board. The raw materials for the preparation of the light-weight high-strength gypsum board include:

[0035]

[0036] In the embodiment of the present application, the ion blocker may be selected from any one or more of polyvinyl alcohol, carboxymethyl cellulose, polyacrylamide, sodium alginate and vinyl acetate-ethylene copolymer emulsion.

[0037] In an embodiment of the present application, the plaster of paris may be clinker of industrial by-product gypsum.

[0038] Optionally, the plaster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap