Alkali-activated high-volume tailings cement brick and preparation method thereof

A high-volume, cement brick technology, applied in the field of building materials, can solve the problems of low compressive strength and crack resistance, inability to achieve good cementation, and increase the amount of iron ore tailings doping, etc., to eliminate Potential safety hazards, saving money, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0027] The preparation of alkali-activated high-volume tailings cement bricks includes the following steps:

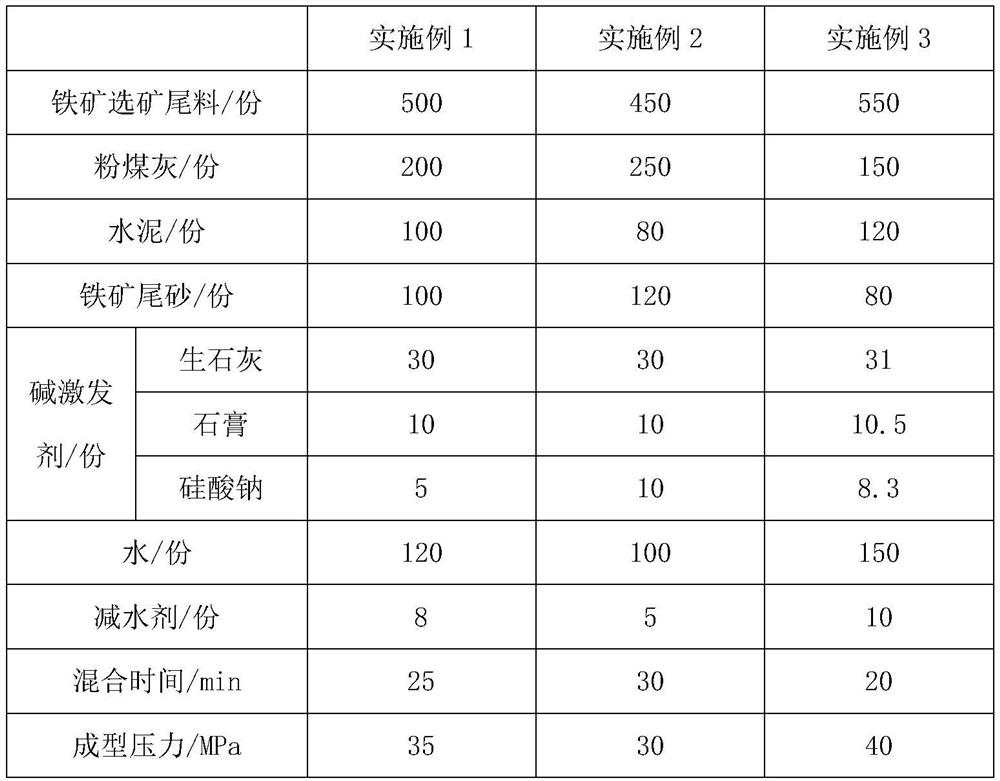

[0028] Mix quicklime, gypsum and sodium silicate to obtain an alkali activator, then mix the alkali activator with iron ore beneficiation tailings, fly ash, cement, iron ore tailings, water reducing agent and water to obtain a cementitious material, Then it is put into a mold and pressed into shape to obtain the alkali-activated high-volume tailings cement brick. Wherein the consumption of each raw material that embodiment 1~3 adopts, stirring mixing time and molding pressure are as shown in table 1:

[0029] Table 1

[0030]

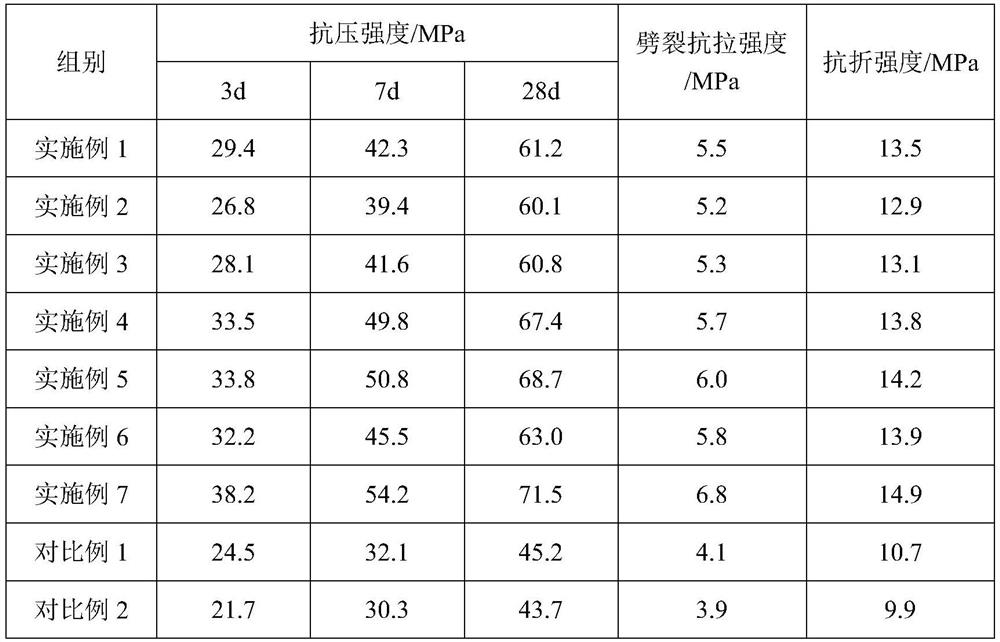

Embodiment 4

[0032] The amount of each raw material is the same as that in Example 1, and the preparation steps are as follows: first mix and stir iron ore dressing tailings, fly ash, alkali activator and 20 parts of water for 15 minutes, then add cement, iron ore tailings, remaining water and water reducer , stirring and mixing for 20min.

Embodiment 5

[0034] Same as Example 1, the difference is that 5 parts of ammonium lauryl ether sulfate, a surfactant, is also added to the alkali activator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com