Cemented filling material for mines as well as preparation method and application thereof

A technology for cementing filling materials and mines, which is applied to fillings, mining equipment, earthwork drilling and mining, etc. It can solve problems such as poor filling effect, poor mechanical properties, and subsidence, and achieve reduced slump, strong acid resistance, and good cementation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

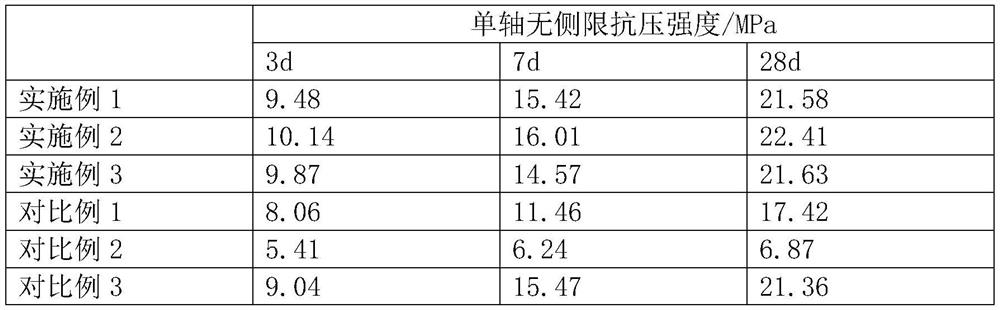

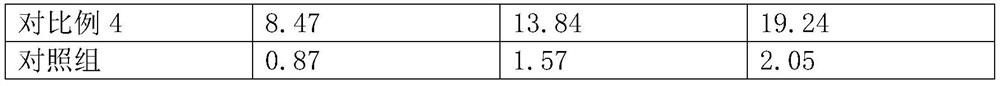

Examples

Embodiment 1

[0033] A cemented filling material for mines, comprising the following raw materials in parts by mass: 11 parts of desulfurized gypsum, 11 parts of hematite, 100 parts of gangue, 6 parts of fly ash, 26 parts of slag, 16 parts of copper-containing waste, and 1.5 parts of water reducer , 50 parts of water. Wherein, the molar ratio of the iron oxide in the hematite to the metallic copper in the copper-containing waste is 1:0.5.

[0034] Preparation:

[0035] 1) Weigh the raw materials according to the above parts by mass;

[0036] 2) Mix hematite with copper-containing waste, calcinate at a temperature of 780° C. for 4 hours, and pulverize to obtain a mixture powder;

[0037] 3) Mix desulfurization gypsum, slag, fly ash, and water reducer to obtain a mixed powder, then add gangue and the mixture, add water, mix evenly, dry, and pulverize to obtain cemented filling materials for mines.

Embodiment 2

[0039] A cemented filling material for mines, comprising the following raw materials in parts by mass: 15 parts of desulfurized gypsum, 15 parts of hematite, 120 parts of gangue, 8 parts of fly ash, 24 parts of slag, 14 parts of copper-containing waste, and 2 parts of water reducer , 60 parts of water. Wherein, the molar ratio of the iron oxide in the hematite to the metallic copper in the copper-containing waste is 1:0.4.

[0040] Preparation:

[0041] 1) Weigh the raw materials according to the above parts by mass;

[0042] 2) mixing hematite with copper-containing waste, calcining for 3 hours at a temperature of 800° C., and pulverizing to obtain a mixture powder;

[0043] 3) Mix desulfurization gypsum, slag, fly ash, and water reducing agent to obtain a mixed powder, then add gangue and the mixture, add water and mix evenly, let stand for 12 hours, dry, and crush to obtain cemented filling materials for mines.

Embodiment 3

[0045] A cemented filling material for mines, comprising the following raw materials in parts by mass: 8 parts of desulfurized gypsum, 6 parts of hematite, 80 parts of gangue, 3 parts of fly ash, 28 parts of slag, 18 parts of copper-containing waste, and 1 part of water reducer , 40 parts of water. Wherein, the molar ratio of the iron oxide in the hematite to the metallic copper in the copper-containing waste is 1:0.6.

[0046] Preparation:

[0047] 1) Weigh the raw materials according to the above parts by mass;

[0048] 2) mixing hematite with copper-containing waste, calcining at a temperature of 750° C. for 5 hours, and pulverizing to obtain a mixture powder;

[0049] 3) Mix desulfurization gypsum, slag, fly ash, and water reducer to obtain a mixed powder, then add gangue and the mixture, add water, mix evenly, dry, and pulverize to obtain cemented filling materials for mines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com