A kind of pre-alkalized inorganic mineral polymer-based quick repair mortar and preparation method thereof

An inorganic mineral, repairing mortar technology, applied in the field of building materials, can solve the problem of early setting time, and achieve the effects of fast opening time, simple operation and fast strength development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

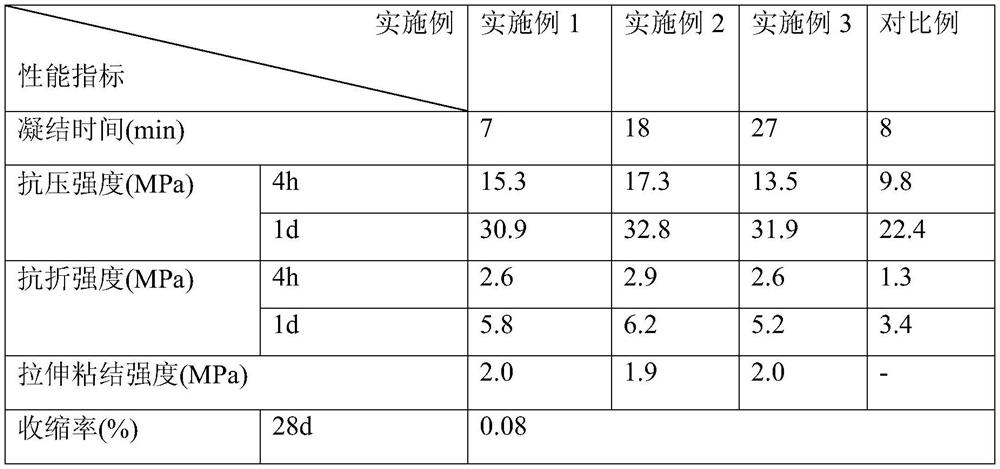

Examples

Embodiment 1

[0036] The invention discloses a pre-alkaline inorganic mineral polymer-based rapid repair mortar, which uses raw materials including: pre-lye, slag, coagulant, fly ash for increasing flow, sand and water. Wherein, the mass fraction of each raw material is: pre-alkali is 39 parts (wherein, the silicon-aluminum material that pre-alkali comprises comprises 18 parts of fly ash for adjusting composition, 5 parts of silica fume; The alkali excitation that pre-alkali comprises In liquid, 4 parts of sodium hydroxide, 12 parts of water glass), 95 parts of slag, 4 parts of saturated aqueous solution of calcium hydroxide, 1 part of saturated aqueous solution of sodium sulfate, 15 parts of fly ash for increasing flow, 120 parts of sand, and 18 parts of water .

[0037] A preparation method of pre-alkaline inorganic mineral polymer base fast repair mortar, comprising the following steps:

[0038] (1) according to the formula of above-mentioned alkali excitation liquid, by proportioning, ...

Embodiment 2

[0043] The invention discloses a pre-alkaline inorganic mineral polymer-based rapid repair mortar, which uses raw materials including: pre-lye, slag, coagulant, fly ash for increasing flow, sand and water. Wherein, the mass parts of each raw material are: 37 parts of pre-alkali liquor (wherein, the silicon-aluminum material that pre-alkali liquor comprises comprises 18 parts of fly ash for adjusting composition, 4 parts of silica fume; , 4 parts of sodium hydroxide, 11 parts of water glass), 85 parts of slag, 3 parts of saturated aqueous solution of calcium hydroxide, 18 parts of fly ash for increasing flow, 120 parts of sand, and 20 parts of water.

[0044] A preparation method of pre-alkaline inorganic mineral polymer-based rapid repair mortar is the same as that of Example 1, except that the formula adopts the raw material ratio of this example.

[0045] The setting time of the pre-alkalized inorganic mineral polymer-based rapid repair mortar prepared in this embodiment is ...

Embodiment 3

[0047] The invention discloses a pre-alkaline inorganic mineral polymer-based rapid repair mortar, which uses raw materials including: pre-lye, slag, coagulant, fly ash for increasing flow, sand and water. Wherein, the mass parts of each raw material are: 41 parts of pre-alkali (wherein, the silicon-aluminum material that pre-alkali comprises includes 22 parts of fly ash for adjusting components, 3 parts of silica fume; , 4 parts of sodium hydroxide, 12 parts of water glass), 80 parts of slag, 2 parts of saturated aqueous solution of calcium hydroxide, 25 parts of fly ash for increasing flow, 120 parts of sand, and 18 parts of water.

[0048] A preparation method of pre-alkaline inorganic mineral polymer-based rapid repair mortar is the same as that of Example 1, except that the formula adopts the raw material ratio of this example.

[0049] The setting time of the pre-alkalized inorganic mineral polymer-based rapid repair mortar prepared in this embodiment is 27 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com