Method for eliminating loess collapsibility through microbial grouting

A microbial and collapsible technology, applied in the field of microbial grouting to eliminate loess collapsibility, can solve problems such as insufficient applicability, high implementation cost, and cumbersome implementation, and achieve obvious effects and reduce collapsibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

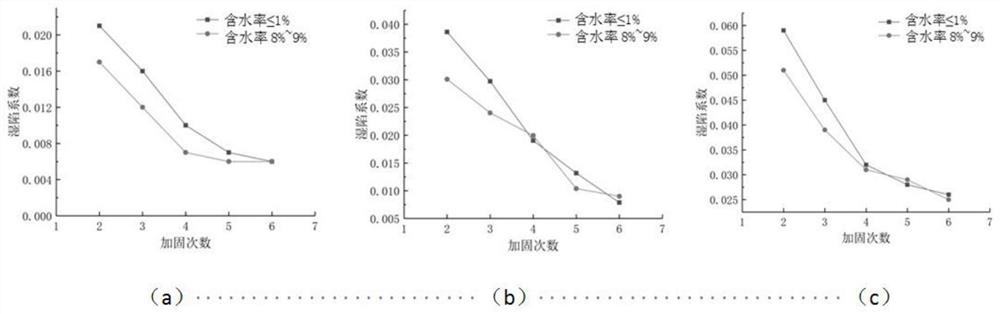

Embodiment 1

[0019] Embodiment 1 (Xianyang site soil):

[0020] A method for eliminating the collapsibility of loess by microbial grouting, specifically comprising the following steps:

[0021] 1) Slowly and evenly add the Bacillus busi solution to the loess at a rate of 5ml / s, let it infiltrate naturally, until the Bacillus busi solution completely infiltrates the soil, and let it stand for 25 minutes;

[0022] 2) Slowly and evenly add 1 mol / L cementing fluid equivalent to the Bacillus busi solution at a rate of 5ml / s to the loess after adding the Bacillus busi solution in step 1, and let it stand for 24 hours at an ambient temperature of 25°C;

[0023] 3) Repeat steps 1)-2) 4 times.

[0024] After testing, the collapsibility coefficient of the site soil dropped from 0.022 to 0.007.

Embodiment 2

[0025] Embodiment 2 (Xianyang site soil):

[0026] A method for eliminating the collapsibility of loess by microbial grouting, specifically comprising the following steps:

[0027] 1) Slowly and evenly add the Bacillus busi solution to the loess at a rate of 8ml / s, let it infiltrate naturally, until the Bacillus busi solution completely infiltrates the soil, and let it stand for 30 minutes;

[0028] 2) Slowly and evenly add 1.5 mol / L cementing fluid equivalent to the Bacillus busi solution at a speed of 8ml / s to the loess after adding the Bacillus busi solution in step 1, and let it stand for 36 hours at an ambient temperature of 27°C;

[0029] 3) Repeat steps 1)-2) 5 times.

[0030] After testing, the collapsibility coefficient of the site soil dropped from 0.022 to 0.005.

Embodiment 3

[0031] Embodiment 3 (Xianyang site soil):

[0032] A method for eliminating the collapsibility of loess by microbial grouting, specifically comprising the following steps:

[0033] 1) Slowly and evenly add the Bacillus busi solution to the loess at a rate of 10ml / s, let it infiltrate naturally, until the Bacillus busi solution completely infiltrates the soil, and let it stand for 35 minutes;

[0034] 2) Slowly and evenly add 2 mol / L cementing fluid equivalent to the Bacillus busi solution at a rate of 10ml / s to the loess after adding the Bacillus busi solution in step 1, and let it stand for 48 hours at an ambient temperature of 30°C;

[0035] 3) Repeat steps 1)-2) 6 times.

[0036] After testing, the collapsibility coefficient of the site soil dropped from 0.022 to 0.006.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com