Fabricated wall and construction method thereof

A prefabricated, wall technology, applied to walls, structural elements, building components, etc., can solve problems such as waste, quickly block slurry overflow, and achieve the effect of reducing overflow, stabilizing shielding, and avoiding slurry waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-6 The application is described in further detail.

[0044] The embodiment of the application discloses a prefabricated wall and a construction method thereof.

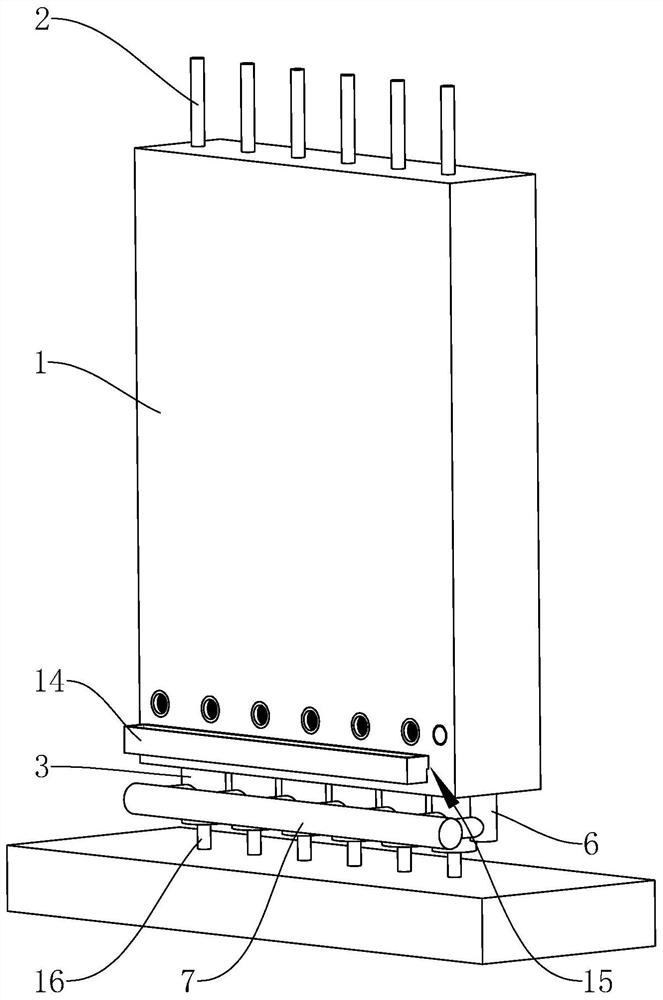

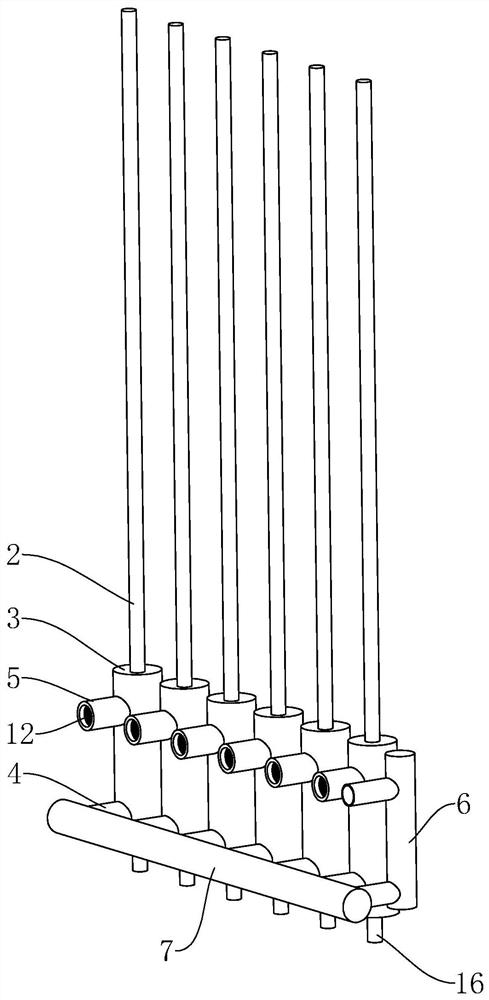

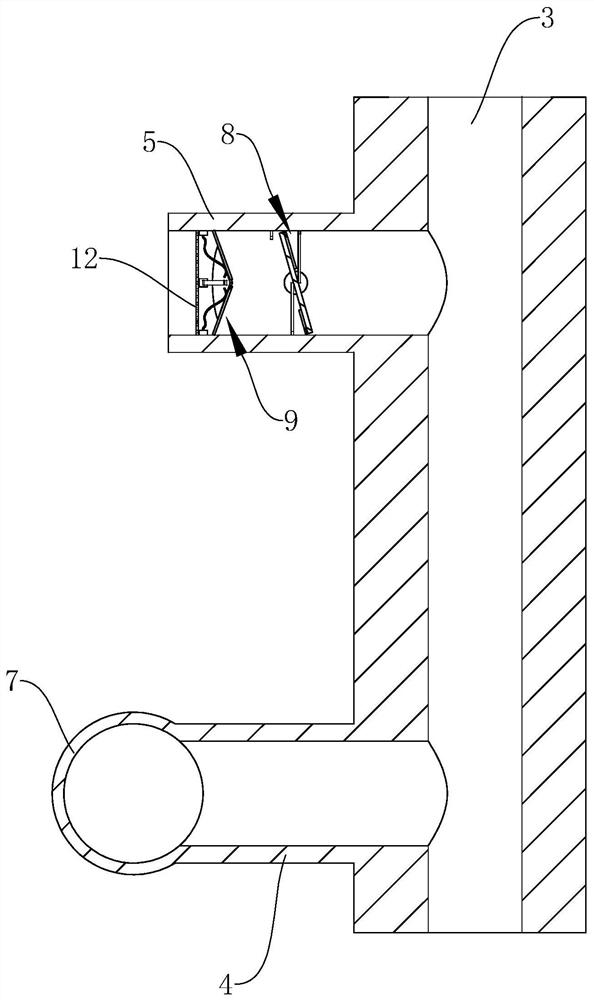

[0045] refer to figure 1 and figure 2 , a prefabricated wall includes a wall body 1, a plurality of connecting steel bars 2 vertically penetrating through the wall body 1, and a sleeve 3 coaxially sleeved on the connecting steel bars 2, by pouring into the wall body 1 Concrete, so that the connecting steel bar 2 is fixed on the wall body 1, the two ends of the connecting steel bar 2 extend to the outside of the wall body 1 respectively, one end of the sleeve 3 is fixed in the wall body 1 by concrete condensation, and the other end extends To the outside of the main body of the wall 1 , one end of the connecting steel bar 2 is plugged into the sleeve 3 .

[0046] refer to figure 1 and figure 2 A grouting tube 4 and a grouting tube 5 are connected to the circular arc per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com