Ceiling mounting structure of cellular boards

A technology for installing structures and honeycomb panels, which is applied in the direction of ceilings, building components, building structures, etc., can solve the problems of no connection relationship between honeycomb panels, difficult alignment during installation, and relative shaking easily, so as to eliminate potential safety hazards , Avoid excessive deformation and moderate deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

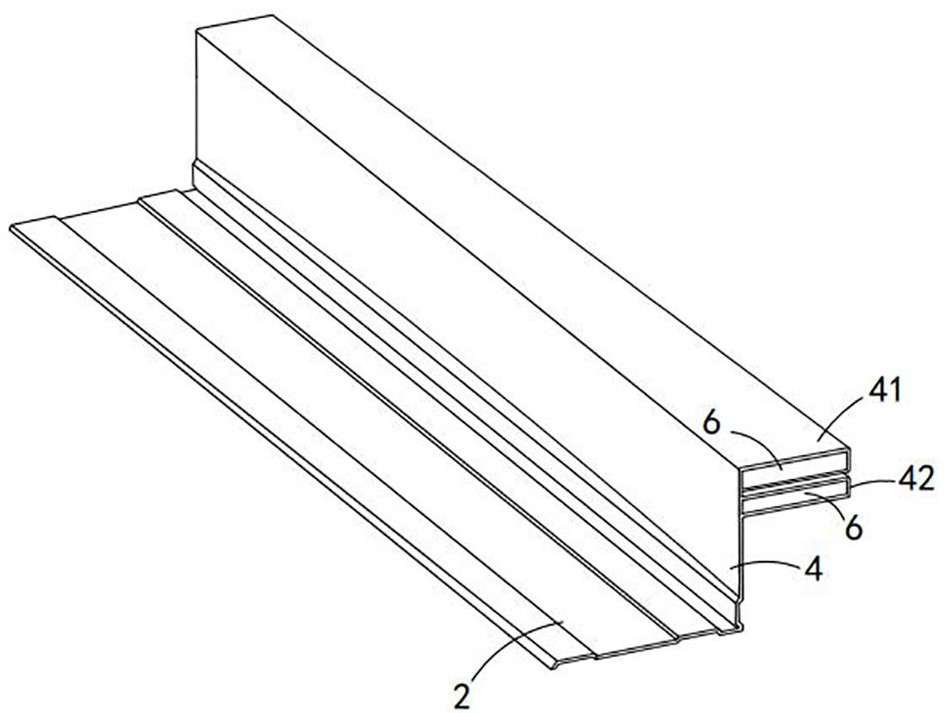

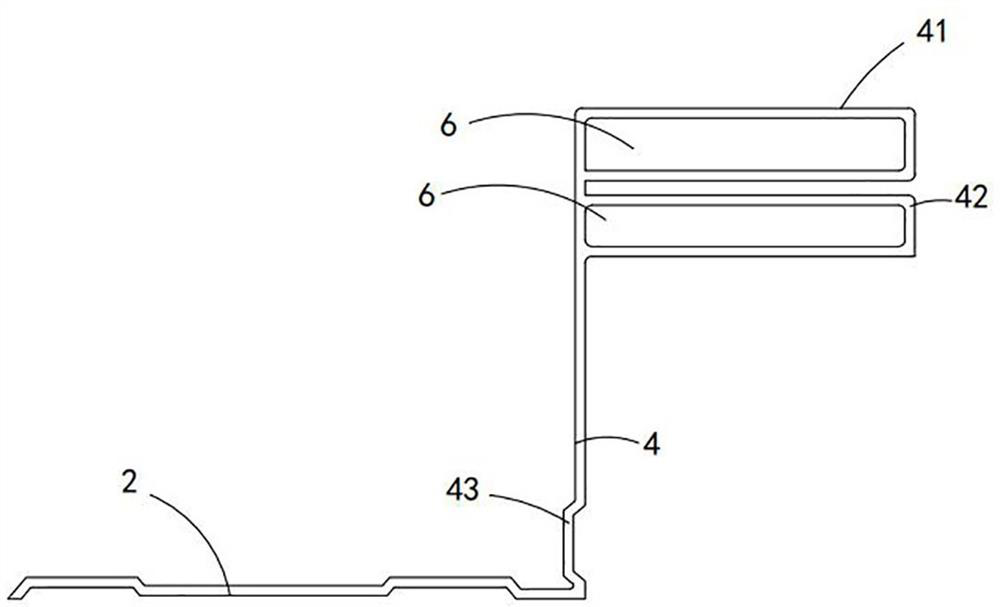

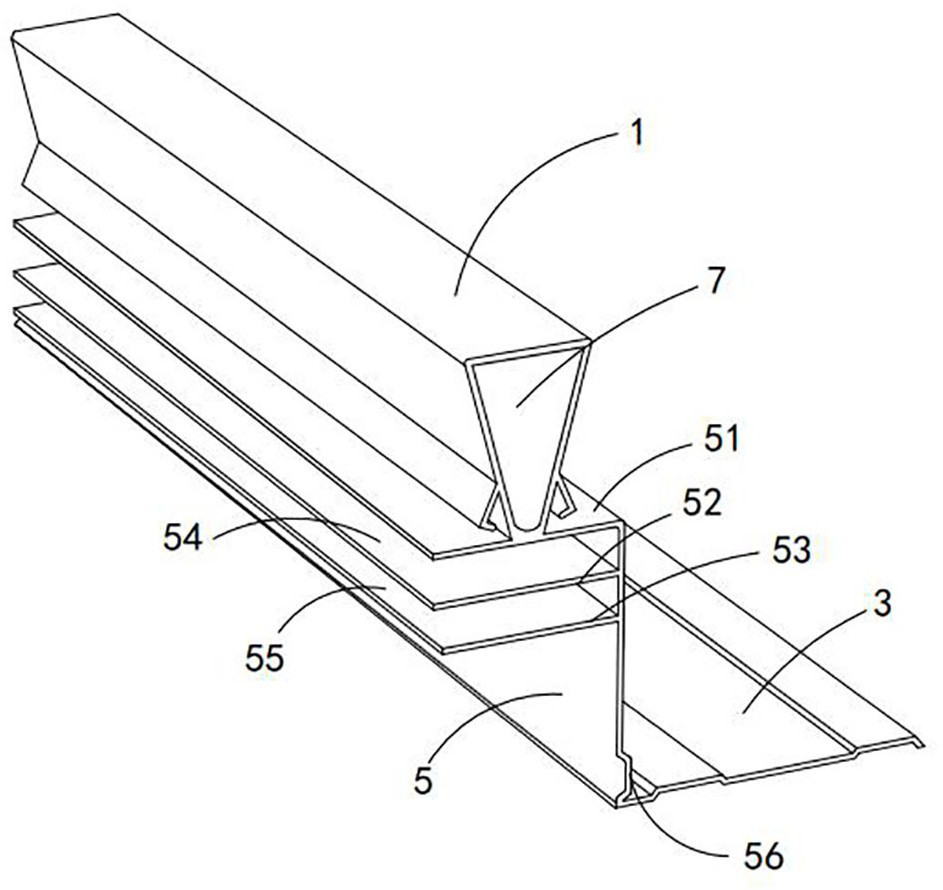

[0026] see Figure 1-4 , this embodiment provides a ceiling installation structure of honeycomb panels, including a ceiling 1, a first honeycomb panel (not shown in the figure), a second honeycomb panel (not shown in the figure), a first connecting plate 2 and a second honeycomb panel Two connection boards 3 .

[0027] Both the first honeycomb panel and the second honeycomb panel are arranged horizontally, and the first honeycomb panel is located on the left side of the second honeycomb panel. The first connecting plate 2 is pasted and fixed on the top surface of the first honeycomb panel. The right edge of the first connecting plate 2 extends upwards to form the first limiting plate 4. The right side of the first limiting plate 4 is provided with a main card. Block 41. The second connecting plate 3 is pasted and fixed on the top surface of the second honeycomb panel. The left edge of the second connecting plate 3 extends upwards to form a second limiting plate 5. The left s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap