Anti-seismic support hanger operation method

A technology for supporting hangers and accessories boxes, which is applied in the directions of pipeline supports, machines/supports, supporting machines, etc., can solve problems such as affecting installation speed, consuming a lot of time, affecting construction period and cost, and avoiding the increase in construction period and cost. The effect of avoiding the increase of the construction period and improving the installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

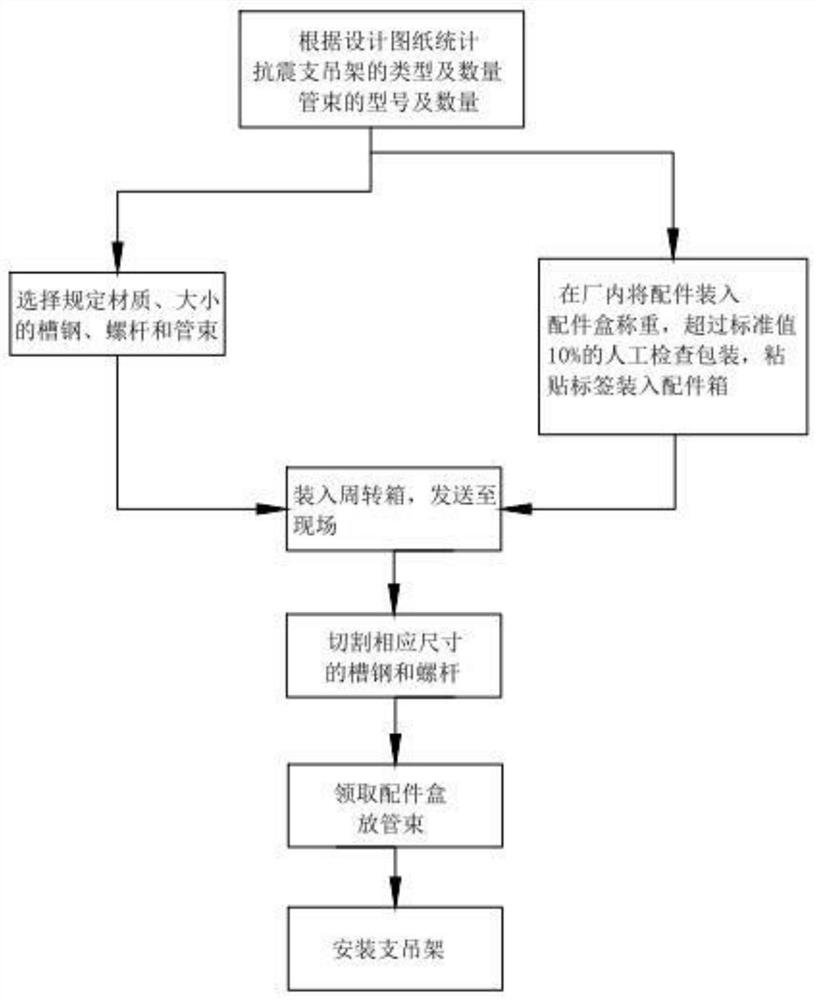

[0025] Such as figure 1 In the shown embodiment, a kind of anti-seismic hanger work method comprises the following steps:

[0026] S1: According to the design drawings, count the types of seismic supports and hangers, the quantity of each type, and the model and quantity of tube bundles; there are many types of seismic supports and hangers, such as single-tube door-type seismic supports and hangers, single-tube side longitudinal seismic supports For hangers, multi-tube lateral anti-seismic supports and hangers, multi-tube side longitudinal anti-seismic supports and hangers, multi-tube door-type lateral anti-seismic supports, etc., except for channel steel, screw rods and tube bundles, the quantity of other parts of the same type of anti-seismic supports is limited. Are the same. The project in this example requires 50 sets of multi-tube lateral seismic support hangers, 50 sets of multi-tube side longitudinal anti-seismic support hangers, 20 sets of multi-tube door-type latera...

Embodiment 2

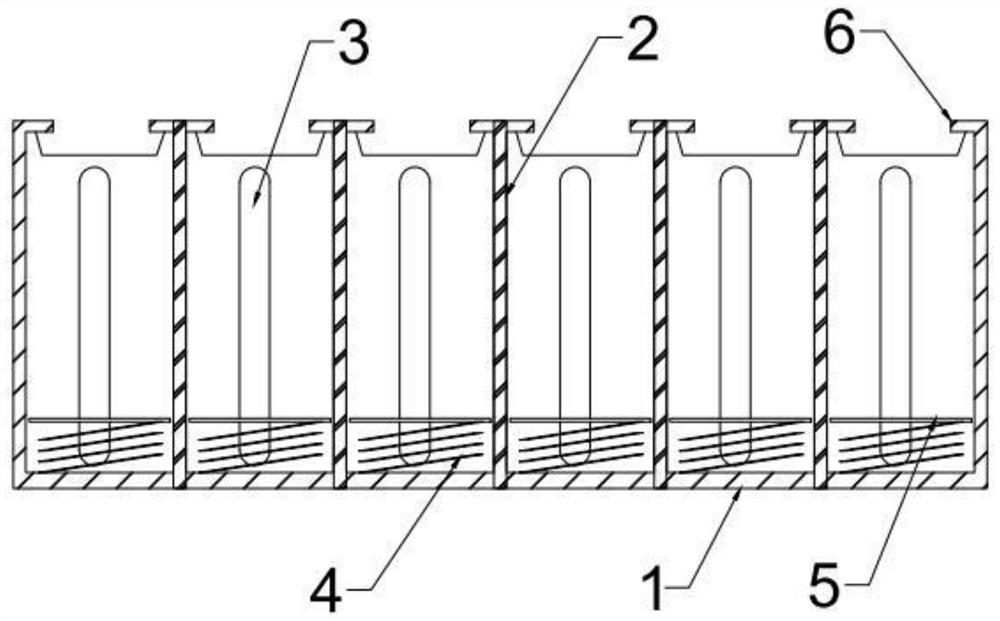

[0032] A working method for an anti-seismic support and hanger, the steps of which are basically the same as those in Embodiment 1, the difference being that: figure 2 As shown, the interior of the accessory box 1 in step 3 is provided with a partition 2, which divides the box packing space into two rows and six rows of accessory box placement areas, and each placement area has a visible window on the side wall 3. The viewing window extends from the lower side to the upper side and can be used to view each accessory box in the placement area. The accessory box is provided with an elastic support at the bottom of each placement area. The elastic support is a spring 4 and a support plate 5. One end of the spring is against the Rely on the bottom surface of the placement area, the other end supports the support plate, the accessory box is stacked on the support plate, and the side of the accessory box near the top is provided with a pick-and-place opening, and the size of the pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com