Method and device for correcting temperature measuring equipment

A technology of temperature measurement equipment and calibration method, which is applied to measurement devices, electrical devices, thermometers, etc., can solve the problems of low calibration accuracy and long calibration time of temperature measurement devices, so as to improve calibration accuracy, shorten calibration time, The effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

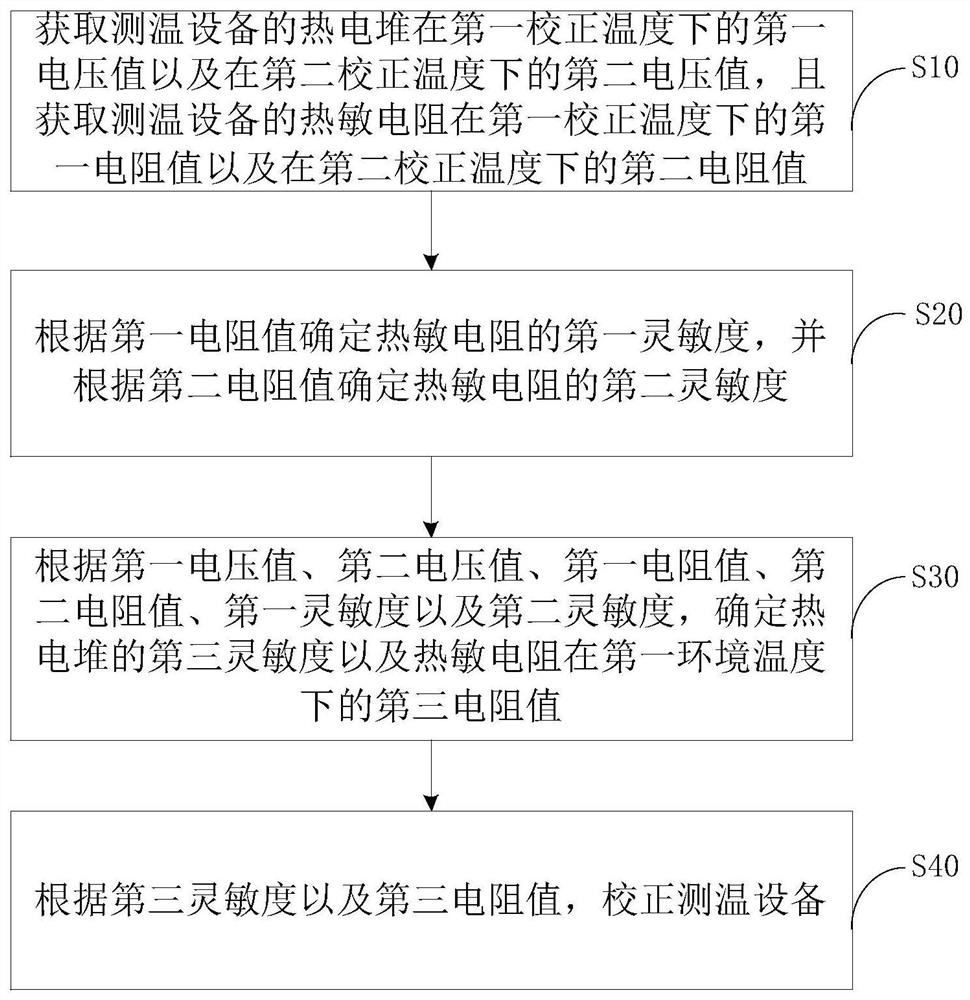

[0064] refer to figure 2 , figure 2 As the first embodiment of the calibration method of the temperature measuring equipment of the present invention, the calibration method of the temperature measuring equipment includes the following steps:

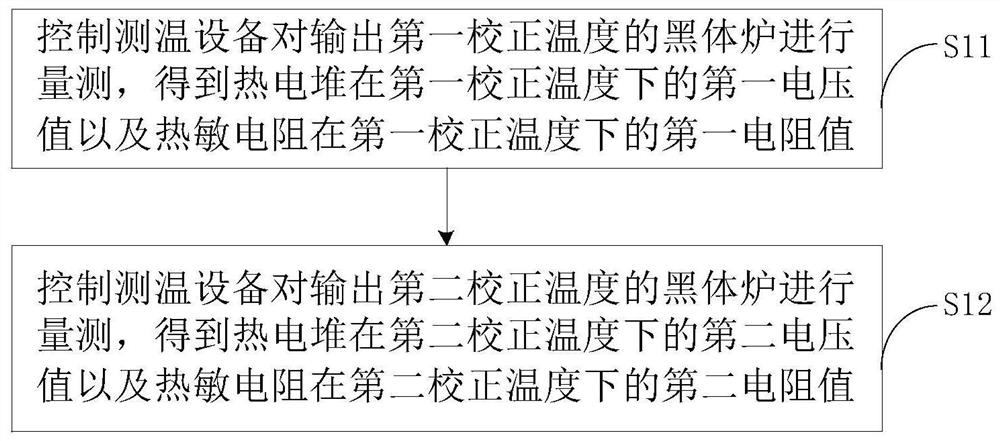

[0065] Step S10, obtaining the first voltage value of the thermopile of the temperature measuring device at the first calibration temperature and the second voltage value at the second calibration temperature, and obtaining the temperature of the thermistor of the temperature measuring device at the first calibration temperature The first resistance value and the second resistance value at the second calibration temperature.

[0066] In this embodiment, the executor is the calibrating device of the temperature measuring device. For the convenience of description, the device is used below to refer to the calibrating device of the temperature measuring device. The temperature measurement equipment has a measurement temperature range. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com