Power plant CT secondary through-flow method

A power plant and flow-through technology, which is applied in the direction of electric winding test, measurement of electric variables, measuring devices, etc., can solve the problems of long flow time, high work intensity, and poor test convenience, so as to achieve strong practicability and improve test efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0041] This embodiment provides a CT secondary flow method in a power plant, including:

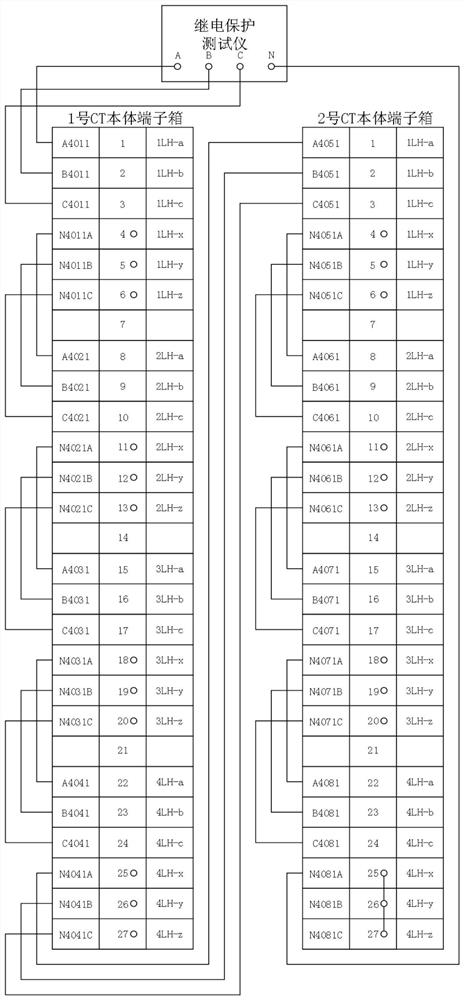

[0042] Connect all the current circuits of each CT in series, and check the correctness and completeness of the wiring of all CT secondary circuits by applying current to one place of a local terminal box during the CT secondary flow test.

[0043] By applying currents of different amplitudes and phase sequences, the correctness of the CT secondary circuit is further checked, and the correctness of the generator-transformer protection cabinet, fault recording cabinet, DCS background sampling and parameter settings is checked at the same time.

[0044] ginseng figure 1 As shown (only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com