Internal tandem cell photovoltaic module and method for manufacturing package structure

A technology of photovoltaic modules and cells, which is applied to electrical components, photovoltaic power generation, circuits, etc., and can solve problems such as difficult cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

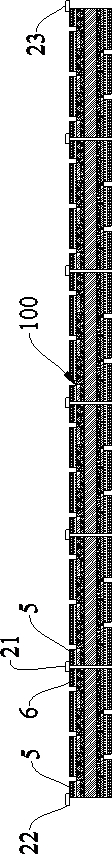

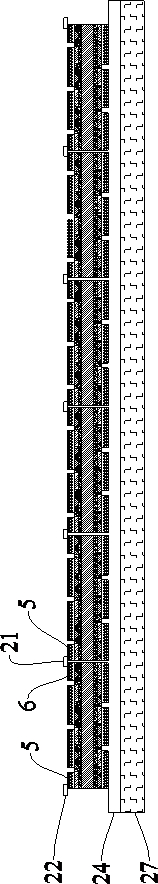

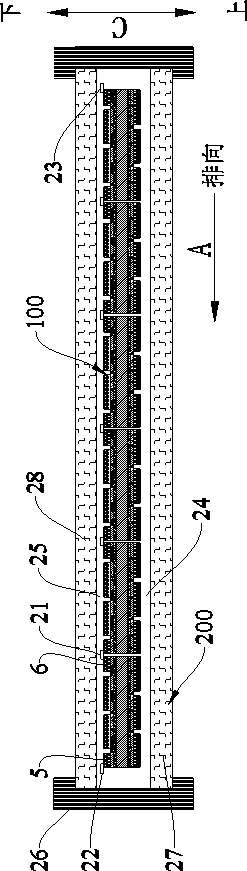

[0032] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0033] Such as Figure 1 to Figure 13 As shown, the internal tandem cell photovoltaic module of the embodiment of the present invention, the internal tandem cell photovoltaic module includes multiple rows of cells 100 groups and packaging components 200 arranged in a row, and each row of cells 100 groups includes a plurality of cells 100, the battery sheet 100 includes a plurality of battery sections connected in series along the row direction and has a first electrode 5 and a second electrode 6, such as Figure 6 As shown, the first electrode 5 and the second electrode 6 are respectively the positive electrode and the negative electrode of the battery sheet 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com