Novel chip mounter chip mounting pressure automatic regulation and control device

A control device and placement machine technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, and can solve problems that affect the quality of placement, damage, and loose fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

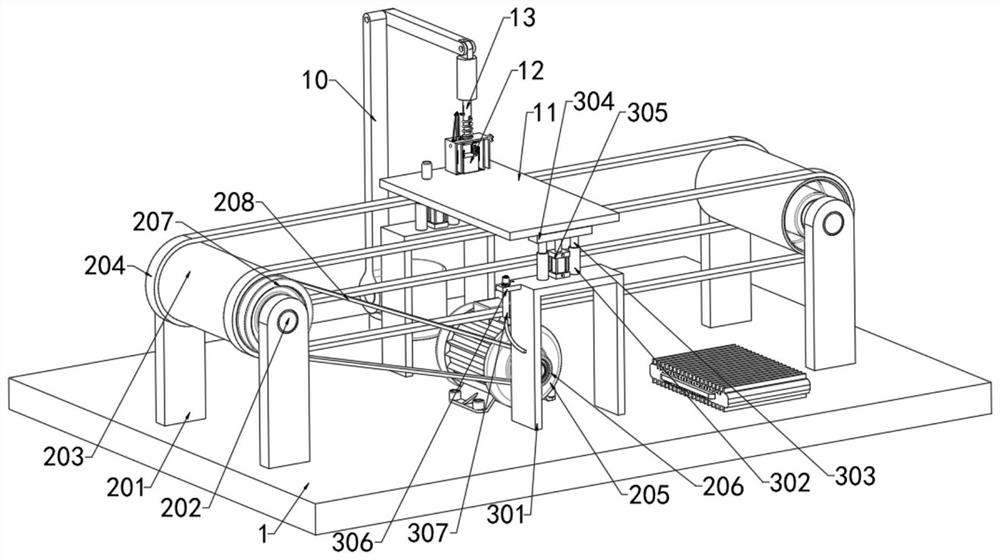

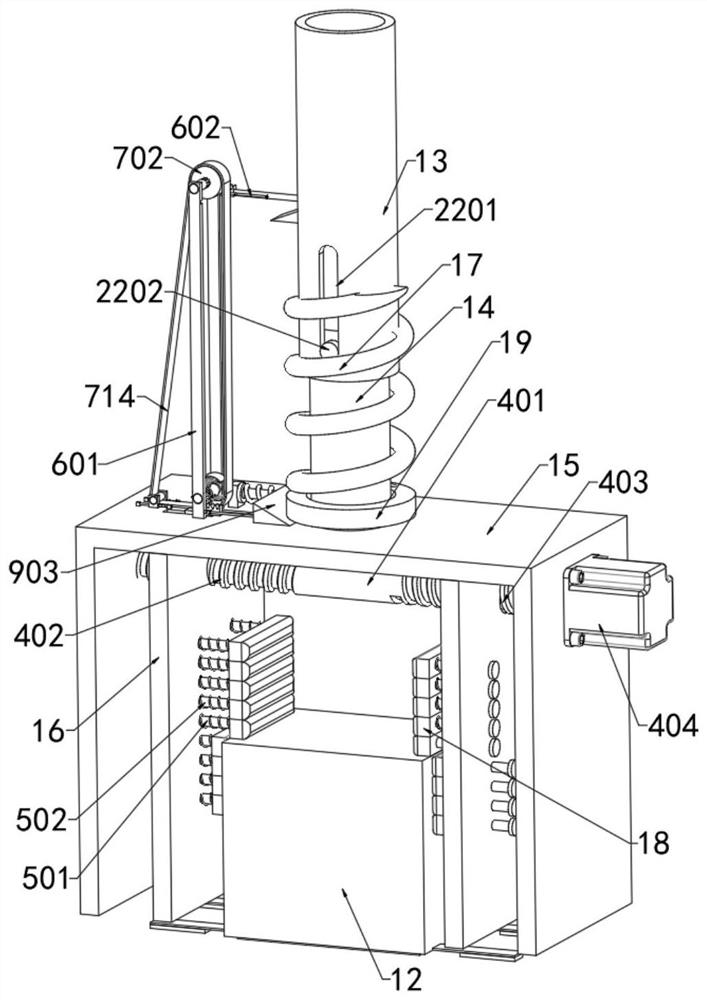

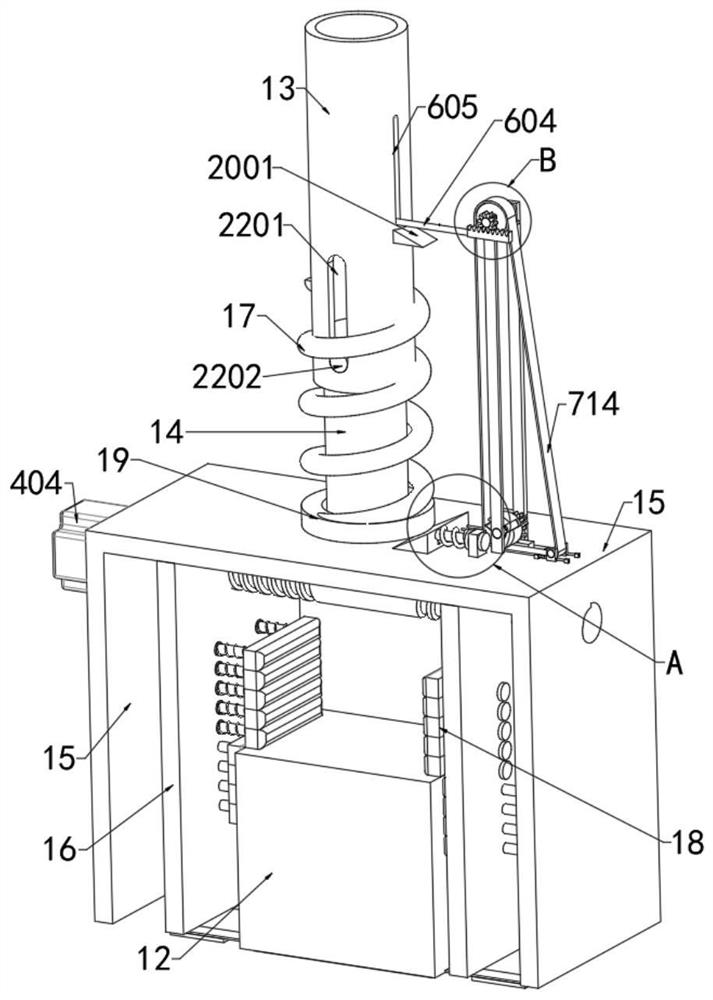

[0038] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the exemplary examples are intended to be construed as not intended to limit the scope of the invention.

[0039] The postmaker, also known as "mounting machine", in the production line, it is configured after the dispensing machine or screen printing machine, which accurately places an apparatus on the PCB board by moving the mount header. The patch machine mainly includes host, working head assembly, visual system, feeding platform, axial structure, transport rail component, nozzle station, air source component, and input and operating components. Among them, the feed platform includes a step feed device, and a sheet receiving bracket or the like.

[0040] The inventors of the SMT placement process further investigation and found that: the traditional placement machine after the patch, the patch when the PCB is completed is examined, and found that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com