Self-cleaning surface cleaning machine

A cleaning machine and self-cleaning technology, used in cleaning machinery, cleaning equipment, manual floor scrubbing machinery, etc., can solve the problem of not solving the problem of water overflow, not considering the cleaning of sewage suction ports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

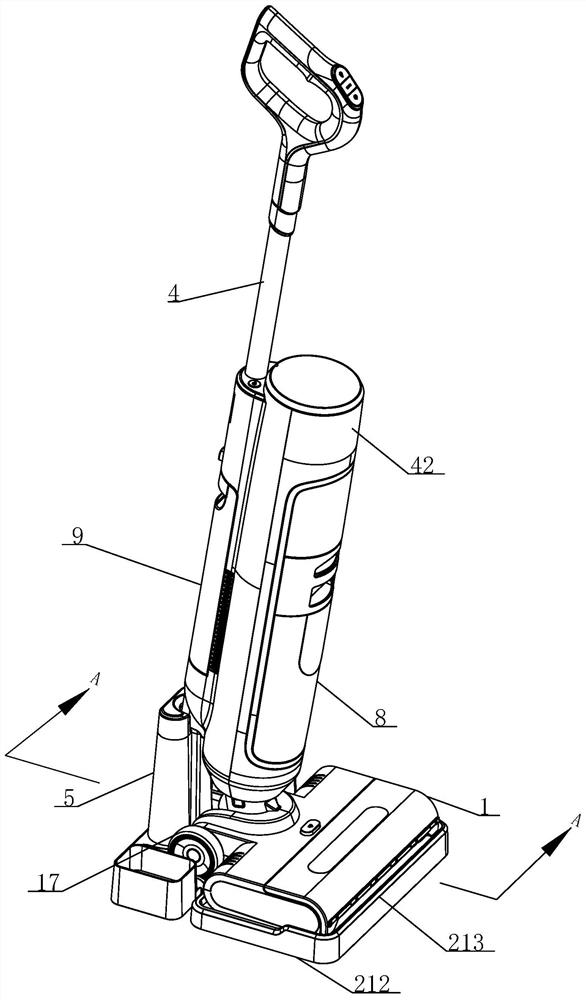

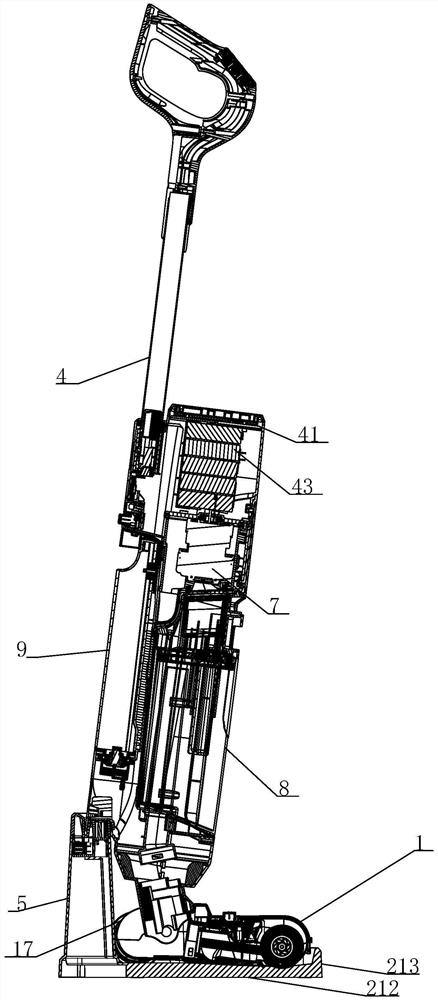

[0036] A kind of self-cleaning surface cleaning machine of the present invention, as Figure 1 to Figure 4 As shown, a surface cleaning machine with good self-cleaning effect includes a body 1, a cleaning dock 2, a cleaning roller 3 located at the bottom of the body 1, a handle bar 4 rotatably connected to the body, and a suction assembly. The dirt assembly includes a dirt suction fan 7 arranged on the handle bar 4, a dirt bucket 8, a dirt suction port 11 located in the body 1 facing the cleaning roller 3, and a delivery pipe 15 connecting the dirt suction port 11 and the dirt bucket 8 , the handle bar 4 is also provided with a water tank 9, in the present embodiment, the water tank 9 is located at the rear side of the dirt bucket 8, and an electric control unit 41 (not shown) is also arranged above the dirt bucket 8, The control part 41 and the battery pack 43, the control part 41 and the battery pack 43 are fixed on the handlebar 4, and are covered by the decorative part 42 ...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is the location and structure of the closed ribs.

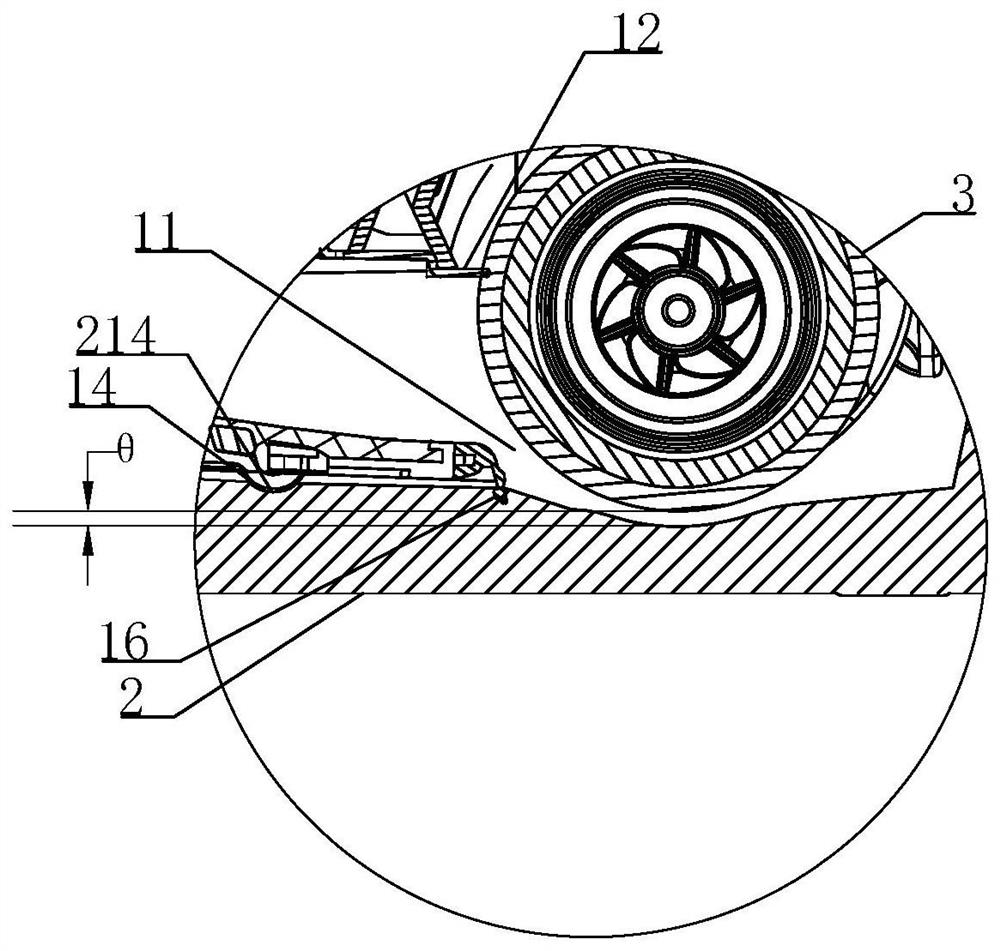

[0047] As another self-cleaning surface cleaner of the present invention, such as Figure 5 and Figure 6 As shown, the closed partition rib 6 is arranged in the receiving area 21, the closed partition rib 6 is arranged on the edge of the cleaning tank 211, and is adjacent to the flexible ground brush 16, and the closed partition rib 6 is connected to the lower surface of the body 1 conflict, the closed rib 6 extends to the coaming plate 213, and the closed rib 6 forms a liquid collection area with the base 212 and the coaming plate 213 on the side of the cleaning tank. When the surface cleaning machine is placed in the receiving area 21 Inside, the flexible floor brush 16 and the sewage suction port 11 are correspondingly located in the liquid collection area, so that the base 212 and the surrounding plate 213 on the side where the closed rib 6 and the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com