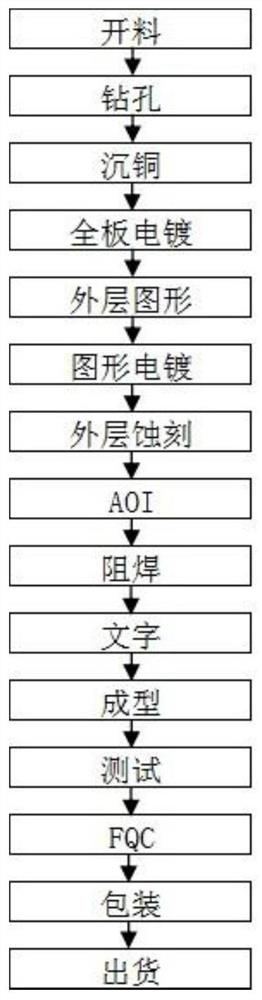

A method and device for multi-axis collaborative blind milling of printed circuit boards

A technology for printed circuit boards and circuit boards, which is used in milling machine equipment, manufacturing tools, and comprehensive factory control. Positioning speed and paste speed, low cost, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

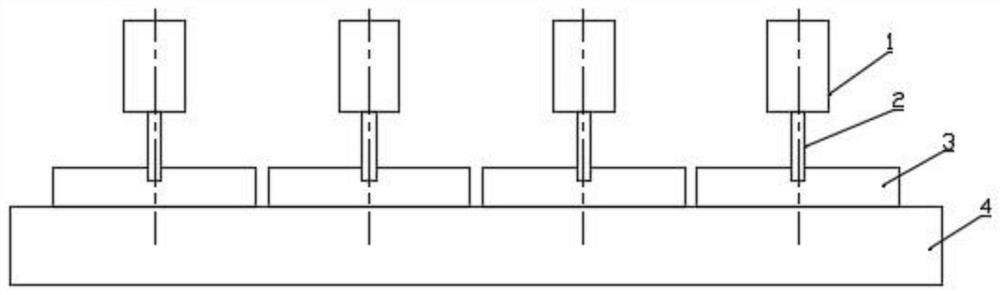

[0044] Wherein, the upper surface of the backing plate 5 can be flattened to form a groove shape, so that the circuit board is fixed on the bottom surface of the groove;

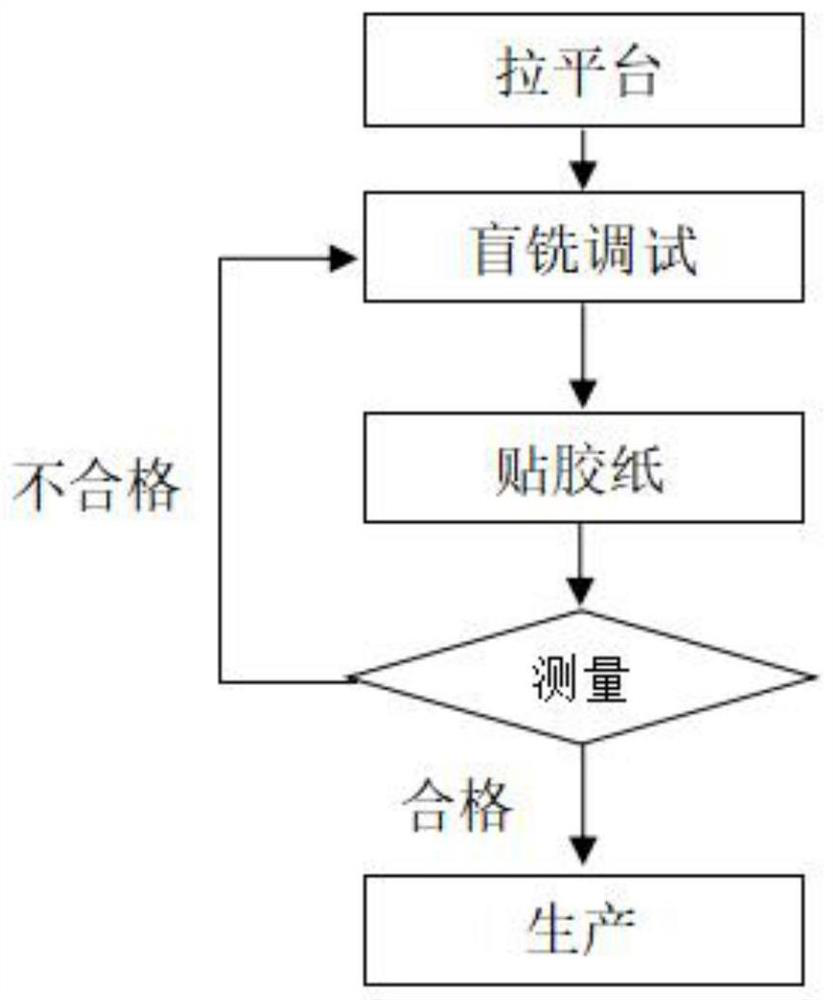

[0055] Mass production: the milling machine that has completed the measurement correction is used for the blind milling batch processing of the circuit board.

[0057] As a preferred embodiment of the above method, the thickness of the adhesive tape is 0.1mm.

[0058] As a preferred embodiment of the above method, the backing board 5 is a medium density wood fiber backing board.

[0062] Wherein, the upper end of the sleeve 703 is provided with a connecting seat 701, and the connecting seat 701 is connected with the connecting plate 903 by bolts;

[0063] Wherein, the telescopic mechanism 702 can be an electric push rod or an air cylinder or an oil cylinder;

[0064] Wherein, the two sides of the sleeve 703 are provided with a connecting rod 704, the connecting rod 704 is provided with a rotating shaft 705, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com