Assembling device for cradle body and plastic part of spinning frame cradle

An assembly device and spinning frame technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the solution of high labor intensity, compact structure, and high-efficiency assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

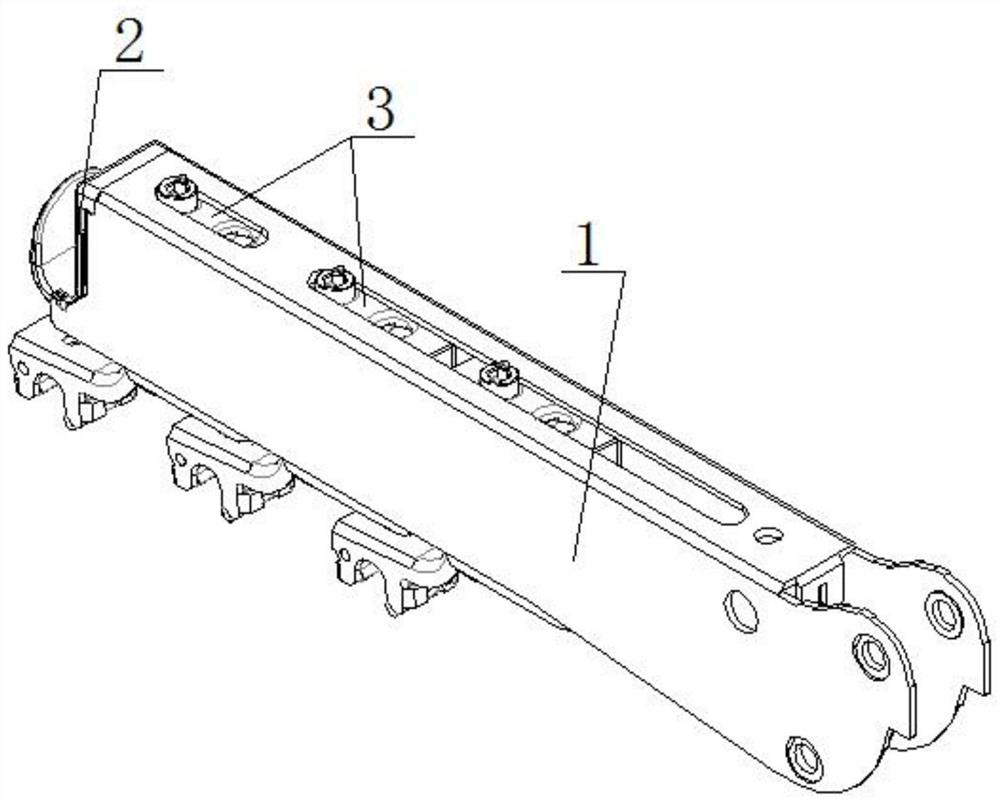

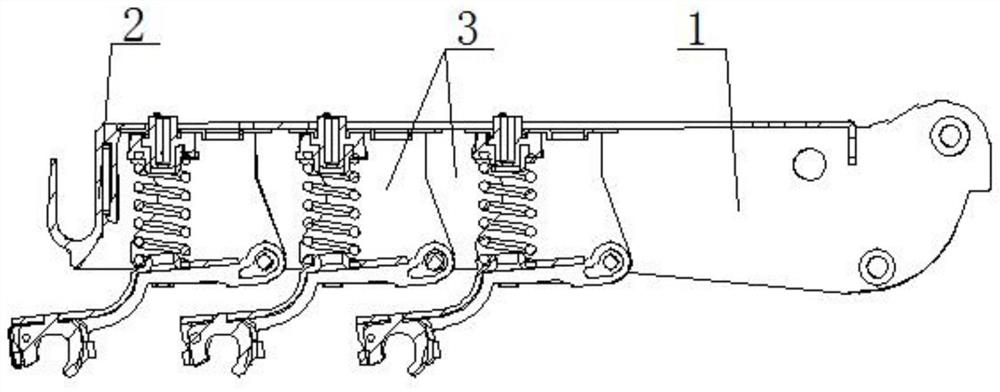

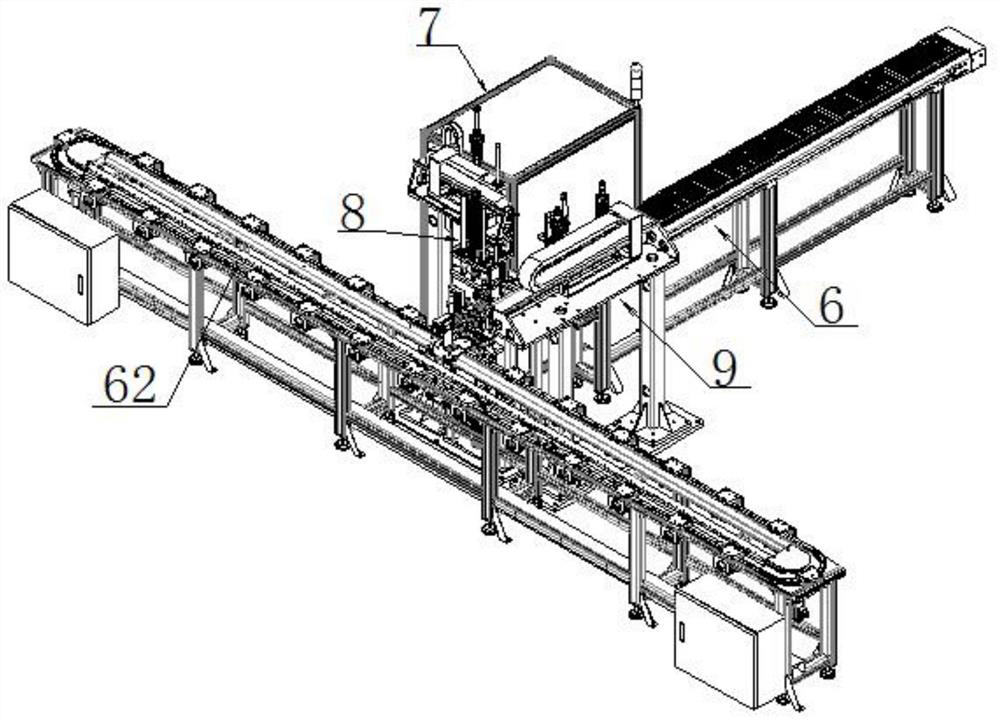

[0051] The assembly device of the cradle frame body and plastic parts of the spinning frame includes a transmission line 62, a workpiece fixture 5, a frame body feeding mechanism 6, a material part feeding mechanism 7, a transfer mechanism 9 and a press-fitting mechanism 8 (see the appendix of the instruction manual). image 3 and 4 ).

[0052] Drive chain 4 is housed by motor on the transmission line 62 (referring to instruction manual appendix Figure 5 ); a plurality of workpiece fixtures 5 are evenly distributed on the driving chain 4; during work, the driving chain 4 can drive the workpiece fixtures 5 to rotate synchronously.

[0053] The workpiece fixture 5 comprises a base plate 11, a fixed pressing plate 16, a movable pressing plate 17, a floating plate 14, a positioning block 15 and a clamping spring 20 (referring to the appended Figure 6 and 7 ).

[0054] The driving chain 4 of the transmission line 62 is fixedly equipped with a bottom plate 11 through the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com