Precise bearing inner ring grinding equipment

A technology for precision bearings and inner rings, which is applied in grinding/polishing equipment, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces. It is convenient to return materials, prevent shaking, and increase the effect of replacement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

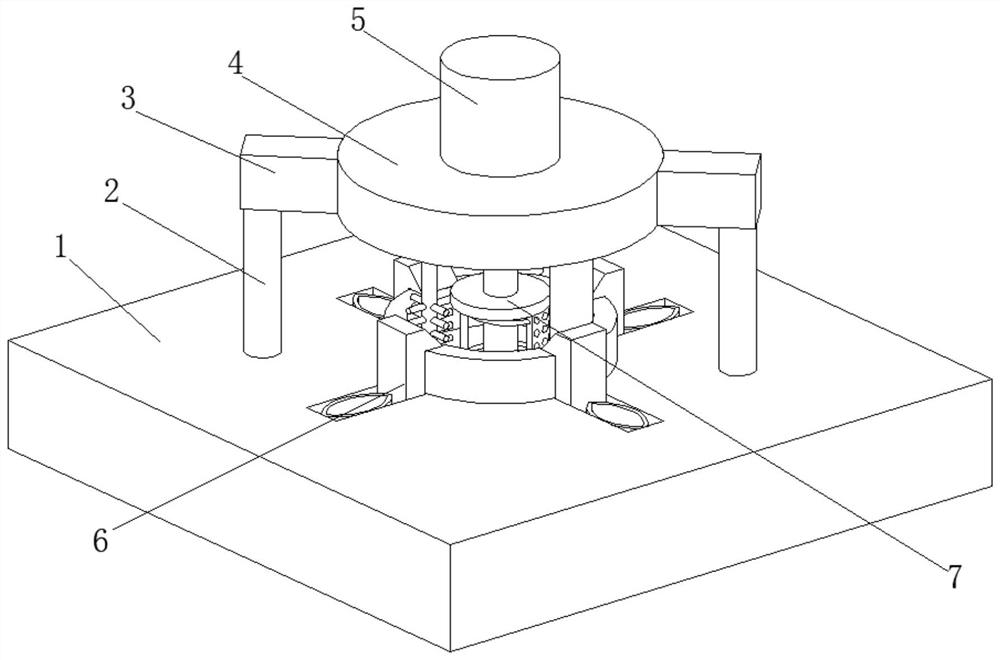

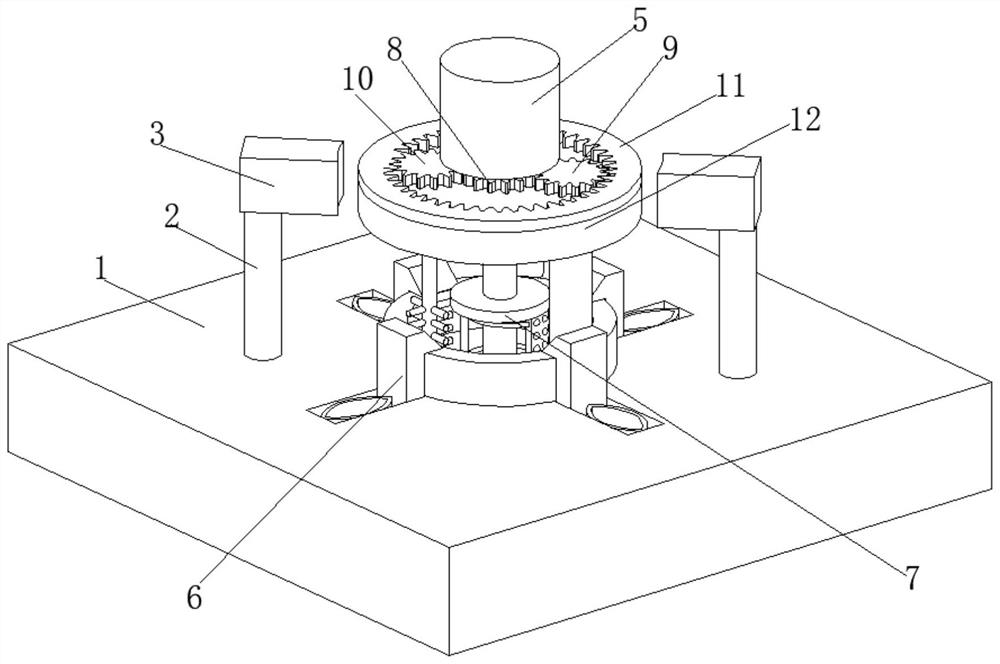

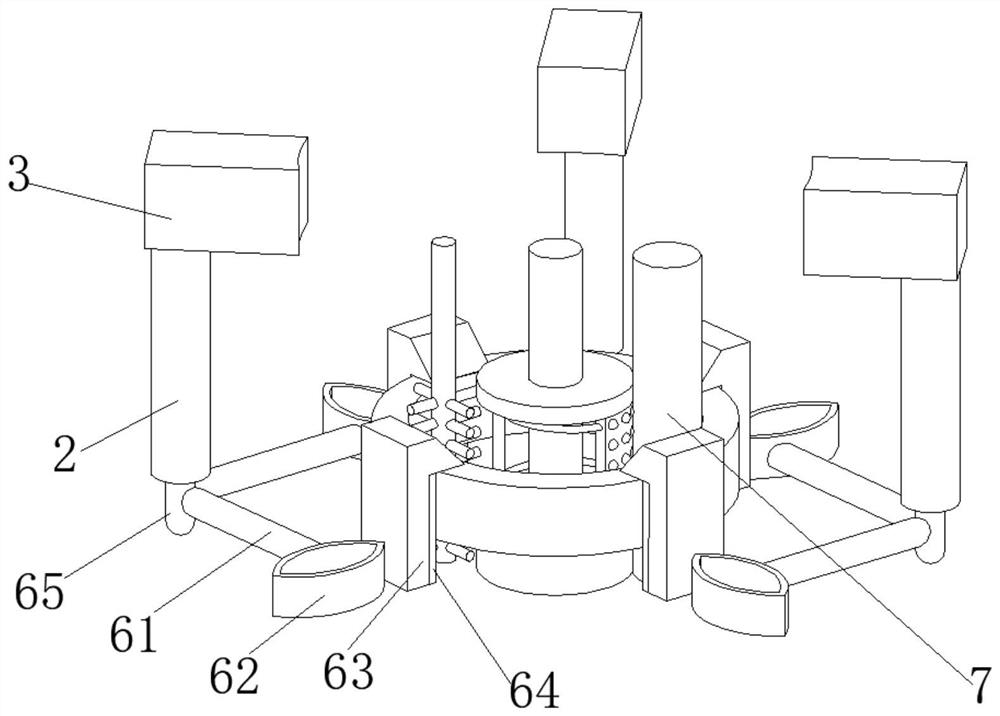

[0026] A precision bearing inner ring grinding equipment, such as Figure 1-Figure 6 As shown, the precision bearing inner ring grinding equipment includes a workbench 1, the top of the workbench 1 is welded with a support column 2, the top of the support column 2 is in contact with a fixed block 3, the surface of the fixed block 3 is welded with a fixed plate 4, and the fixed plate The top of 4 is connected with motor 5 by bolts, the inner wall of workbench 1 is provided with fixing mechanism 6, the bottom end of fixed plate 4 is provided with cleaning mechanism 7, the output end of motor 5 is welded with transmission gear 8, and the surface of transmission gear 8 is respectively No. 1 gear 9 and No. 2 gear 10 are meshed. The surfaces of No. 1 gear 9 and No. 2 gear 10 are meshed with an inner toothed disc 11, and the bottom end of the inner toothed disc 11 is connected with a turntable 12. When the transmission gear 8 drives the No. 1 gear 9 and the No. 2 gear 10 to rotate, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com