Double-rotating-shaft ink-jet printing system and processing technology

An inkjet printing, dual-axis technology, applied to printing devices, printing, typewriters, etc., can solve the problems of difficult microstructure processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

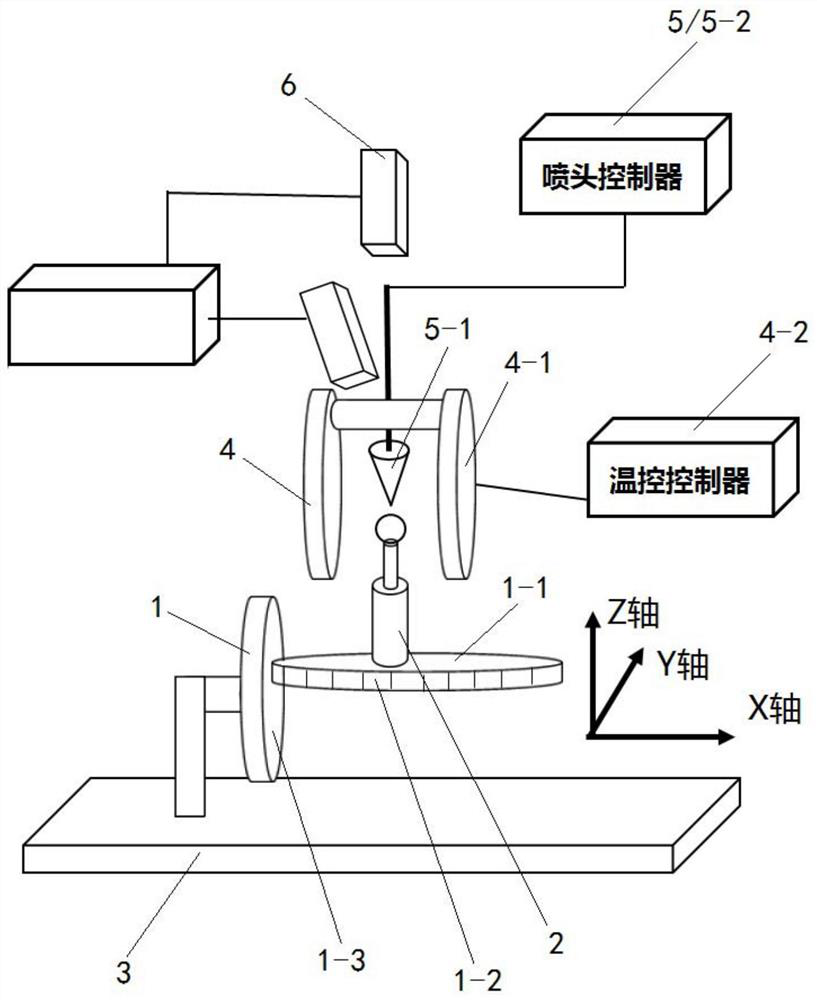

[0021] Such as figure 1 As shown, the dual-axis inkjet printing system includes a biaxial turntable 1, a fixing device 2, a displacement platform 3, a heating device 4, a nozzle device 5 and a photographing device 6, and the biaxial turntable is fixed on a displacement platform through a fixing frame. On the platform, the displacement platform can move horizontally or vertically, and the heating device, nozzle device and photographing device are all arranged above the biaxial turntable, wherein the biaxial turntable is composed of the first turntable 1-1 and the second A three-dimensional turntable composed of turntables 1-3, the outer periphery of the first turntable is provided with an annular chute 1-2, and a closed ring slideway (figure omitted) is provided in the chute, and the first turntable is embedded in the chute and can be Free rotation along the slideway, the chute and the upper surface of the second turntable are fixed at 90°, and the non-center of the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com