Fixing structure of tower crane standard sections

A fixed structure, standard section technology, applied in cranes, mechanical equipment, shafts and bearings, etc., can solve the problems of easy loosening, breakage and loss at the joint of standard sections, and solve the problems of inconvenient jointing, poor stability, and compact overall structure design. , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

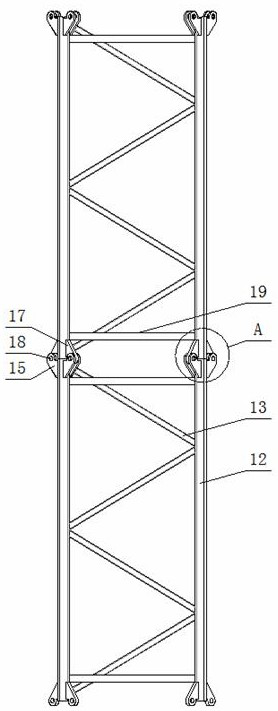

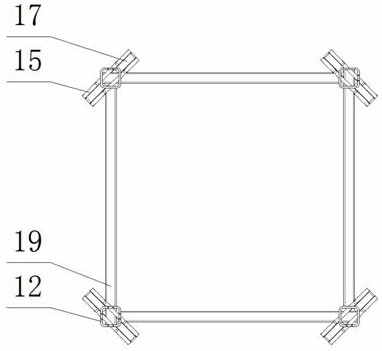

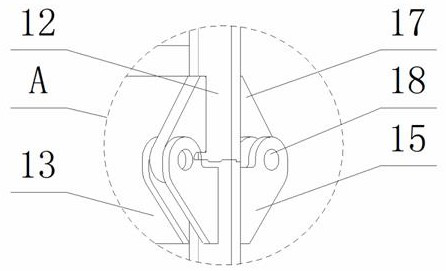

[0029] Embodiment 1: The problems of inconvenient splicing of standard sections and poor stability are solved. This embodiment provides a fixed structure for standard sections of tower cranes. See Figure 1-7 Specifically, it includes a connecting pipe 12, an engaging mechanism, and a limit mechanism, the four connecting pipes 12 are vertically placed in parallel, and a cross bar 19 is provided between the ends of two adjacent connecting pipes 12, Both ends of each cross bar 19 are affixed to the ends of the corresponding connecting pipes 12, and two adjacent connecting pipes 12 are engaged and connected, and both ends of each connecting pipe 12 are provided with a limit mechanism; Between the two connecting pipes 12 there are several pairs of cross-placed reinforcing sloping plates 13, and the two ends of each reinforcing sloping plate 13 are welded and fixed to the side of the corresponding connecting pipe 12 respectively; The ends are respectively welded and fixed to the si...

Embodiment 2

[0031] Embodiment 2: One end of each connecting pipe 12 is recessed with a snap-in groove, and the other end protrudes outward with a snap-in block, and two adjacent connecting pipes 12 are correspondingly snapped into the snap-in groove through the snap-in block Cooperate connection to realize the snap connection of two adjacent connecting pipes; the rest of the structure is the same as that of Embodiment 1.

Embodiment 3

[0032] Embodiment 3: In Embodiment 1, there is also the problem that the internal splicing and engagement of the connecting pipe and the connecting pipe on another set of standard joints is not firm. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0033] In the present invention, the limit mechanism includes a limit rod 25 and a limit plate 210. A limit ring 24 is provided at the top end of the connecting pipe 12, and a limit rod 25 sliding through the limit ring 24 is inserted in the limit ring. 24 below is provided with limit stopper 26 at the bottom of limit bar 25, and connecting pipe 12 inner bottom end is provided with limit plate 210, is positioned at limit plate 210 below and is provided with a pair of inclined block 211 at connecting tube 12 inner bottom port, limit The top of the position rod 25 is inserted into the inner bottom of the corresponding connecting pipe 12 on another set of standard joints; between the inclined block 211 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com