Fabric and wearable equipment

A fabric and surface layer technology, applied in the field of wearable devices, can solve the problem of inability to achieve continuous extraction of skin sweat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0168] The embodiment of the present application provides a kind of preparation method of fabric, comprises the following steps:

[0169] S01. Surface yarn fibers and inner layer yarn fibers respectively, twisting the surface layer yarn fibers to form surface layer yarns, twisting the inner layer yarn fibers to form inner layer yarns;

[0170] S02. Fabric weaving by weaving or knitting.

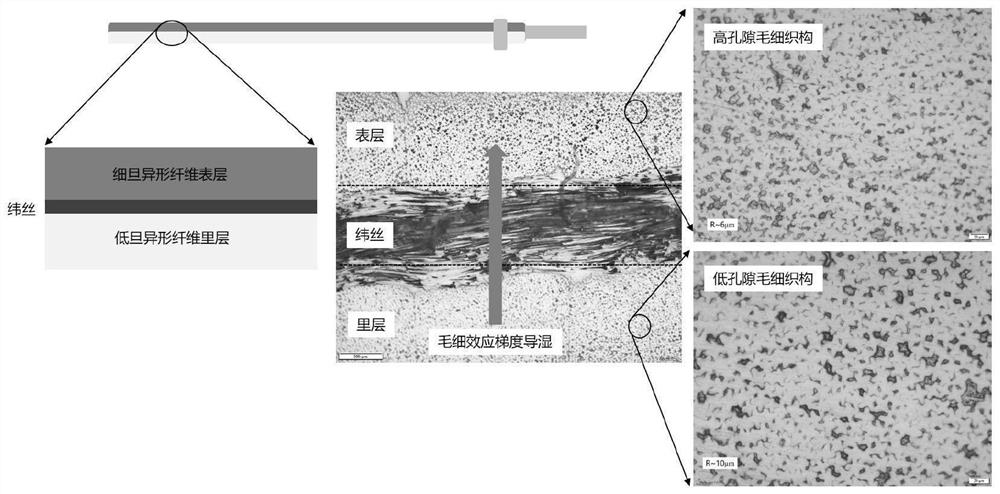

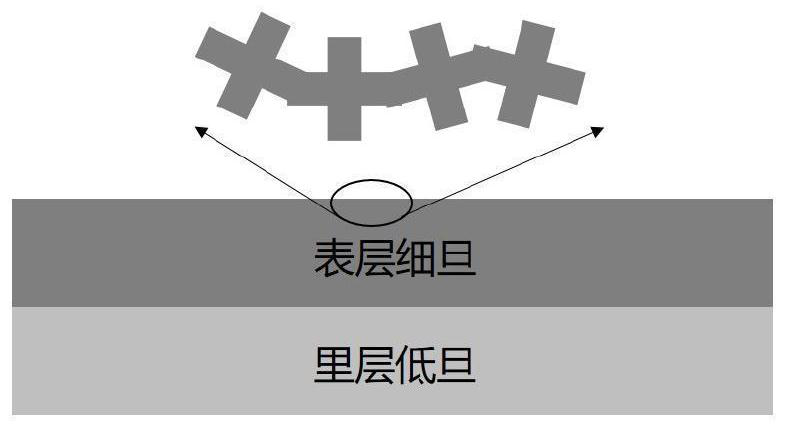

[0171] Specifically, in the above step S01, the selection of the surface layer yarn fibers and the inner layer yarn fibers is as described above. In some embodiments, the linear density of the surface layer yarn fibers is smaller than the linear density of the inner layer yarn fibers. In some embodiments, the difference between the linear density of the surface layer yarn fibers and the inner layer yarn fibers is greater than or equal to 0.5D. In some embodiments, the surface layer yarn fibers have a linear density of 0.1D to 1.0D, and the inner layer yarn fibers have a linear density of 1....

Embodiment 1

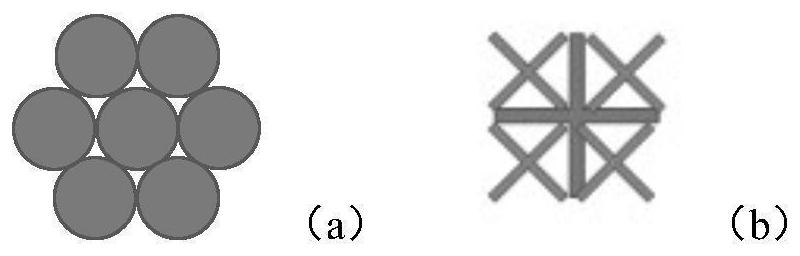

[0191] A fabric watchband comprising an inner layer in contact with the skin, and an outer layer bonded to the inner layer. Wherein, the yarn (surface warp and surface weft) in the surface layer has a linear density of 400D, and is made by twisting cross nylon antibacterial fibers with a linear density of 0.8D, wherein the blade angle of the cross nylon antibacterial fibers is 70°, The degree of irregularity is 50, and the surface energy is 46mN / m; the linear density of the yarns (inner warp and inner weft) in the inner layer is 400D, which is made by twisting cross nylon antibacterial fibers with linear densities of 0.8D and 2D, and 2D cross The blade angle of nylon antibacterial fiber is 70°, the degree of profile is 50, and the surface energy is 46mN / m; and the number of cross nylon antibacterial fibers with a linear density of 2D (low denier) and cross nylon antibacterial fibers with a linear density of 0.8D (fine denier) The ratio is 3:1. The fabric strap has a thickness...

Embodiment 2

[0195] A fabric watchband includes an inner layer in contact with the skin, a middle layer combined with the inner layer, and a surface layer combined with the middle layer. Wherein, the yarn (surface warp and surface weft) in the surface layer has a linear density of 400D, and is made by twisting cross nylon antibacterial fiber with a linear density of 0.9D, wherein in the cross nylon antibacterial fiber, the blade angle is 70°, The degree of profile is 75, and the surface energy is 46mN / m; the yarn (mid-warp and mid-latitude) of the middle layer has a linear density of 300D, which is made by twisting cross hydrophobic modified nylon antibacterial fibers with a linear density of 0.5D, wherein the cross In the nylon antibacterial fiber, the blade angle is 70°, the profile degree is 85, and the surface energy is 22mN / m; the yarn (inner warp and inner weft) linear density in the inner layer is 300D, and the linear density is 0.5D and 1.1D The cross-shaped hydrophobic modified ny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com