Building spray gun capable of effectively improving spraying effect

A construction and spray gun technology, which is applied in the direction of construction, building structure, spraying device, etc., can solve the problems of paint scattering, affecting spraying effect, nozzle tilting, etc., and achieve the effect of improving utilization rate, improving spraying effect and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

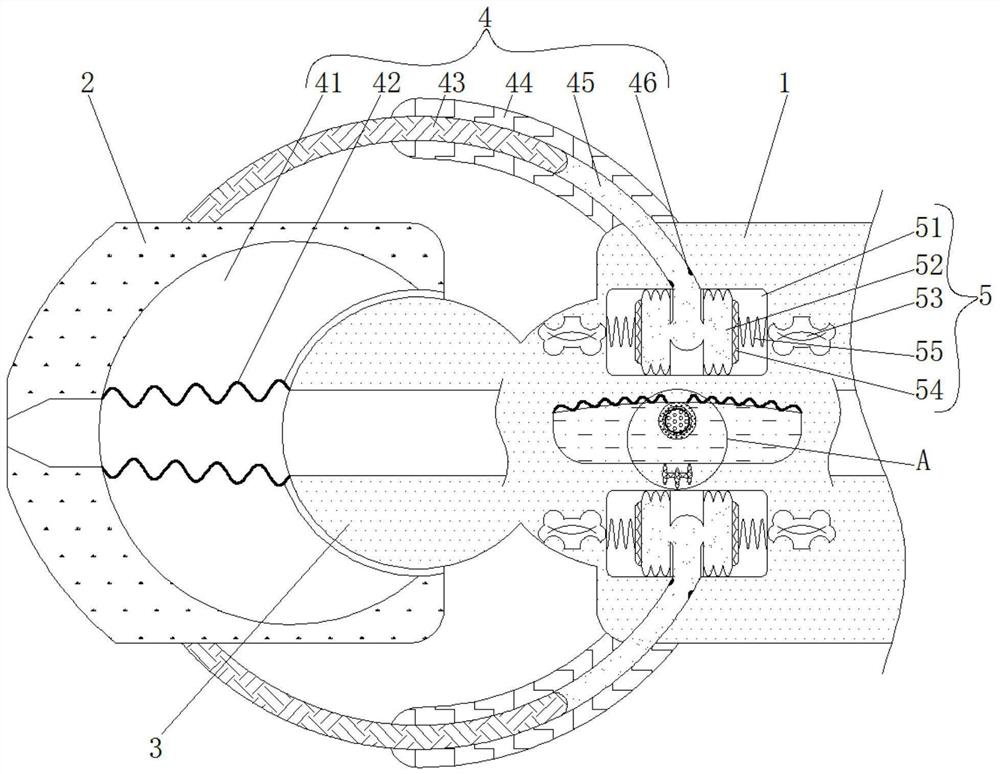

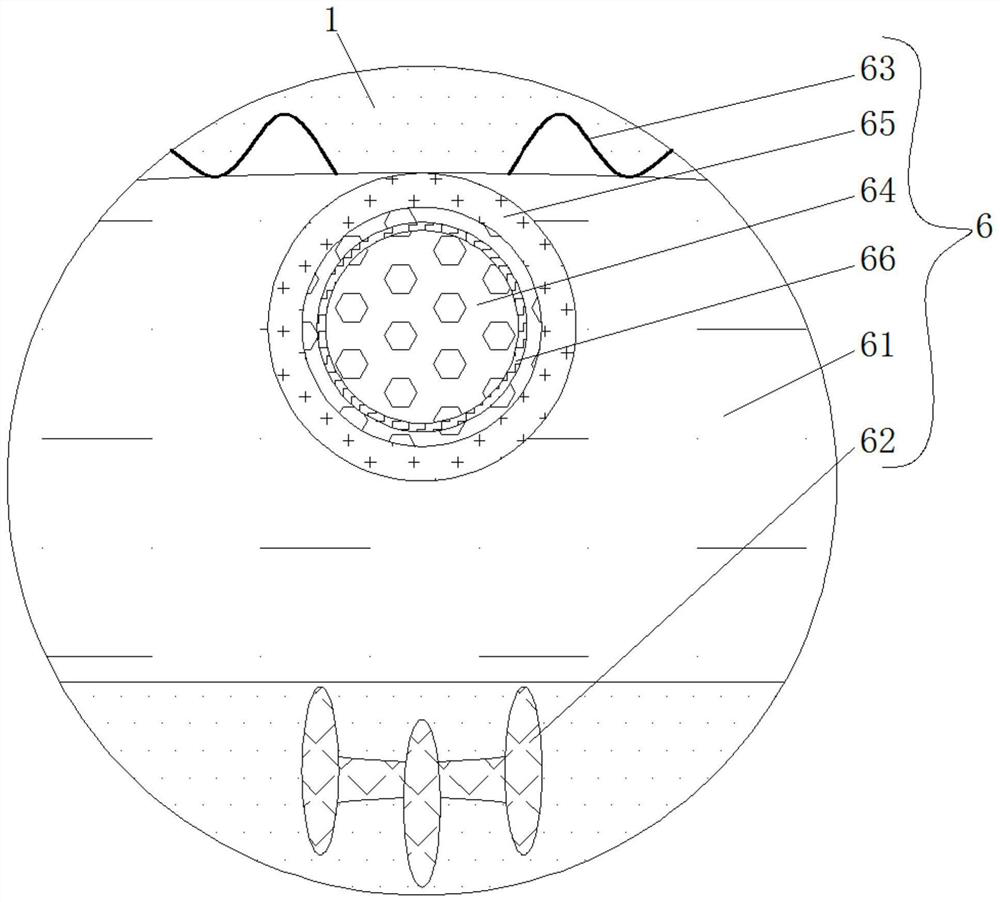

[0027] see Figure 1-4 , a construction spray gun for effectively improving the spraying effect, comprising a spray gun 1, the left side of the spray gun 1 is rotatably connected with a nozzle 2, the left side of the spray gun 1 is provided with a movable ball 3 slidingly connected with the right side of the nozzle 2, and the spray gun 1 The left side and near the top and bottom of the movable ball 3 are movably connected with a transmission mechanism 4 , the inside of the spray gun 1 is movably connected with an actuator 5 , and the inside of the spray gun 1 and close to the inside of the actuator 5 is movably connected with a control mechanism 6 .

[0028] Further, the nozzle 2 rotates up and down around the center of the movable ball 3 and the size of the nozzle 2 is greater than the size of the movable ball 3, the shape of the movable ball 3 is a sphere, and the inside of the movable ball 3 is provided with a paint delivery groove, and the movable ball 3 reaches a limit. T...

Embodiment 2

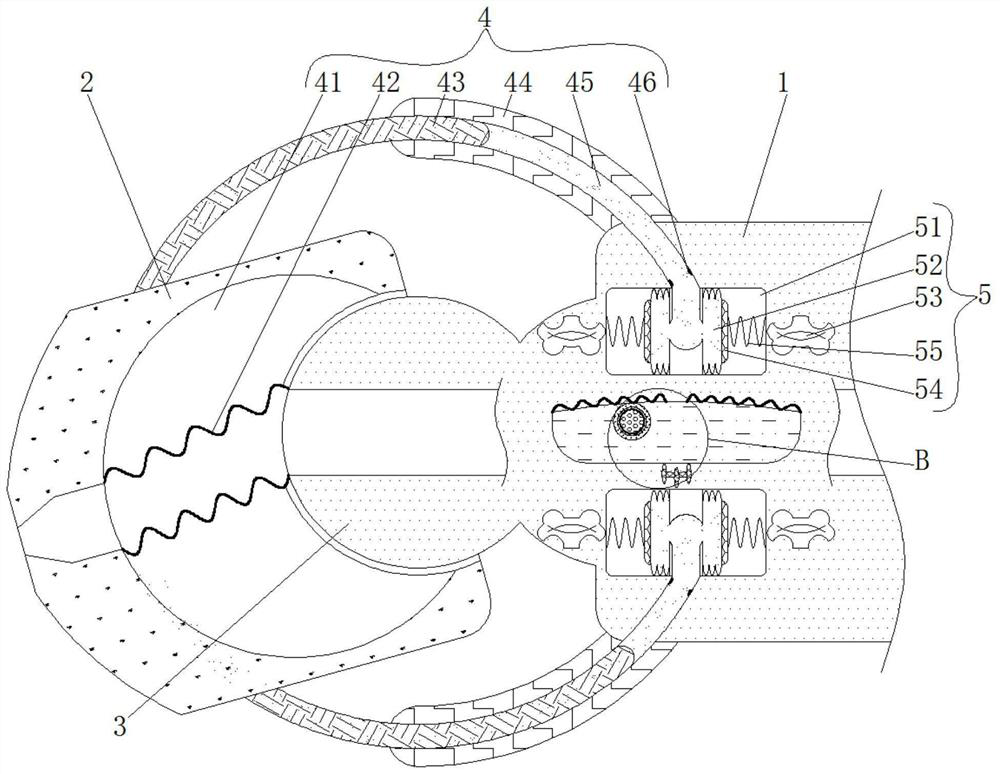

[0033] see Figure 1-4 , a construction spray gun for effectively improving the spraying effect, comprising a spray gun 1, the left side of the spray gun 1 is rotatably connected with a nozzle 2, the left side of the spray gun 1 is provided with a movable ball 3 slidingly connected with the right side of the nozzle 2, and the spray gun 1 The left side and near the top and bottom of the movable ball 3 are movably connected with a transmission mechanism 4 , the inside of the spray gun 1 is movably connected with an actuator 5 , and the inside of the spray gun 1 and close to the inside of the actuator 5 is movably connected with a control mechanism 6 .

[0034] Further, the nozzle 2 rotates up and down around the center of the movable ball 3 and the size of the nozzle 2 is greater than the size of the movable ball 3, the shape of the movable ball 3 is a sphere, and the inside of the movable ball 3 is provided with a paint delivery groove, and the movable ball 3 reaches a limit. T...

Embodiment 3

[0039] see Figure 1-4 , a construction spray gun for effectively improving the spraying effect, comprising a spray gun 1, the left side of the spray gun 1 is rotatably connected with a nozzle 2, the left side of the spray gun 1 is provided with a movable ball 3 slidingly connected with the right side of the nozzle 2, and the spray gun 1 The left side and near the top and bottom of the movable ball 3 are movably connected with a transmission mechanism 4 , the inside of the spray gun 1 is movably connected with an actuator 5 , and the inside of the spray gun 1 and close to the inside of the actuator 5 is movably connected with a control mechanism 6 .

[0040] Further, the nozzle 2 rotates up and down around the center of the movable ball 3 and the size of the nozzle 2 is greater than the size of the movable ball 3, the shape of the movable ball 3 is a sphere, and the inside of the movable ball 3 is provided with a paint delivery groove, and the movable ball 3 reaches a limit. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com