Heat exchange device

A technology of heat exchange device and heat exchange tube, applied in the direction of heat exchanger type, indirect heat exchanger, heat transfer modification, etc. The effect of prolonging the service life and maintenance interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

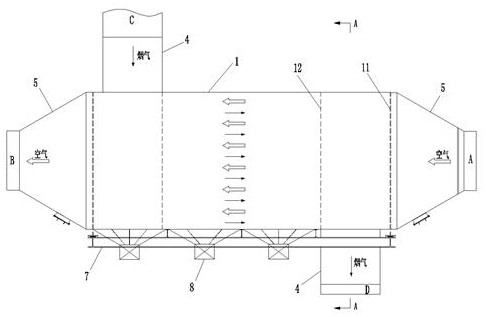

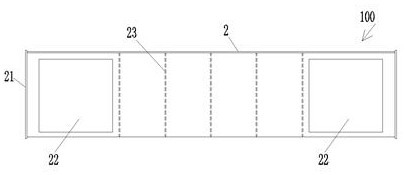

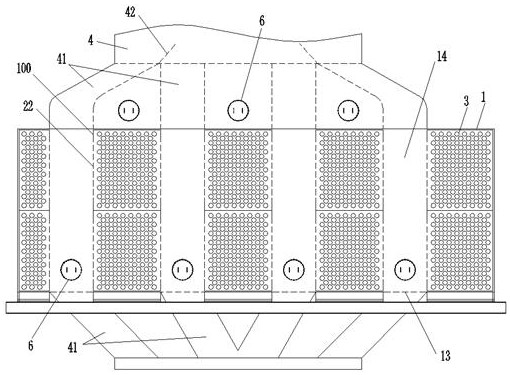

[0029] See figure 1 , figure 2 , a specific embodiment of a heat exchange device, including a cylindrical main casing 1, the two ends of the main casing 1 are respectively sealed with sealing plates 11 so as to form a heat exchange space in the main casing 1, the main casing 1 There are a plurality of heat exchange tubes 3 inside, the heat exchange tubes 3 correspond to the length direction of the main shell 1 and the two ends respectively pass through the corresponding sealing plate 11, and the side wall of the main shell 1 is connected with two first media The two ends of the pipeline 4 and the main shell 1 are respectively connected with the second medium pipeline 5, and the second medium pipeline 5 communicates with each heat exchange tube 3; a plurality of heat exchange module units 100 are detachably installed in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap