Monitoring equipment for food safety production

A technology for monitoring equipment and food safety, applied to electrical equipment components, electrical equipment shells/cabinets/drawers, cleaning methods and utensils, etc., can solve agglomeration, food manufacturing process can not form a transparent, unresponsive food workshop Manufacture safety issues and achieve the effect of clear efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to Figure 6 Shown:

[0029] The invention provides a monitoring device for food safety production,

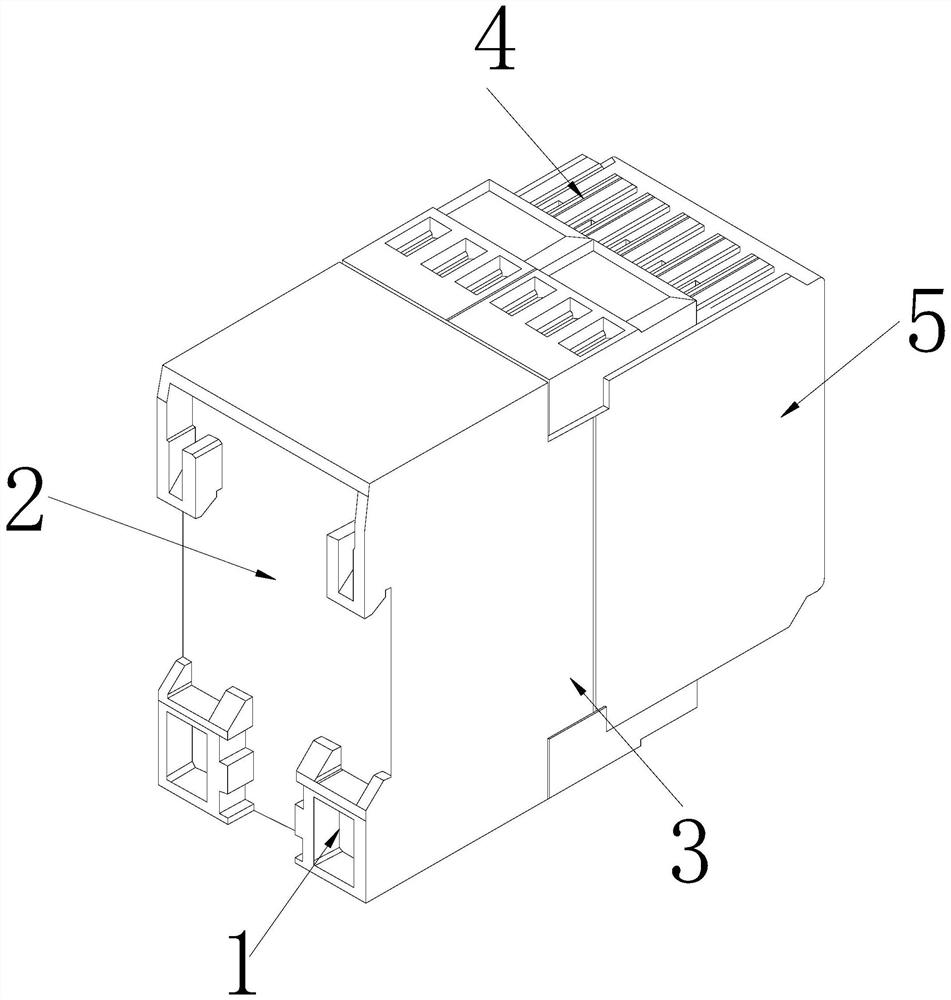

[0030] Its structure includes, fixed frame 1, embedding groove 2, body 3, heat dissipation end 4, monitoring end 5, described fixing frame 1 communicates with embedding groove 2, described body 3 and embedding groove 2 are integrated, and described heat dissipation end 4 Installed on the upper end of the body 3 , the monitoring end 5 is fixedly connected to the lower end of the cooling end 4 .

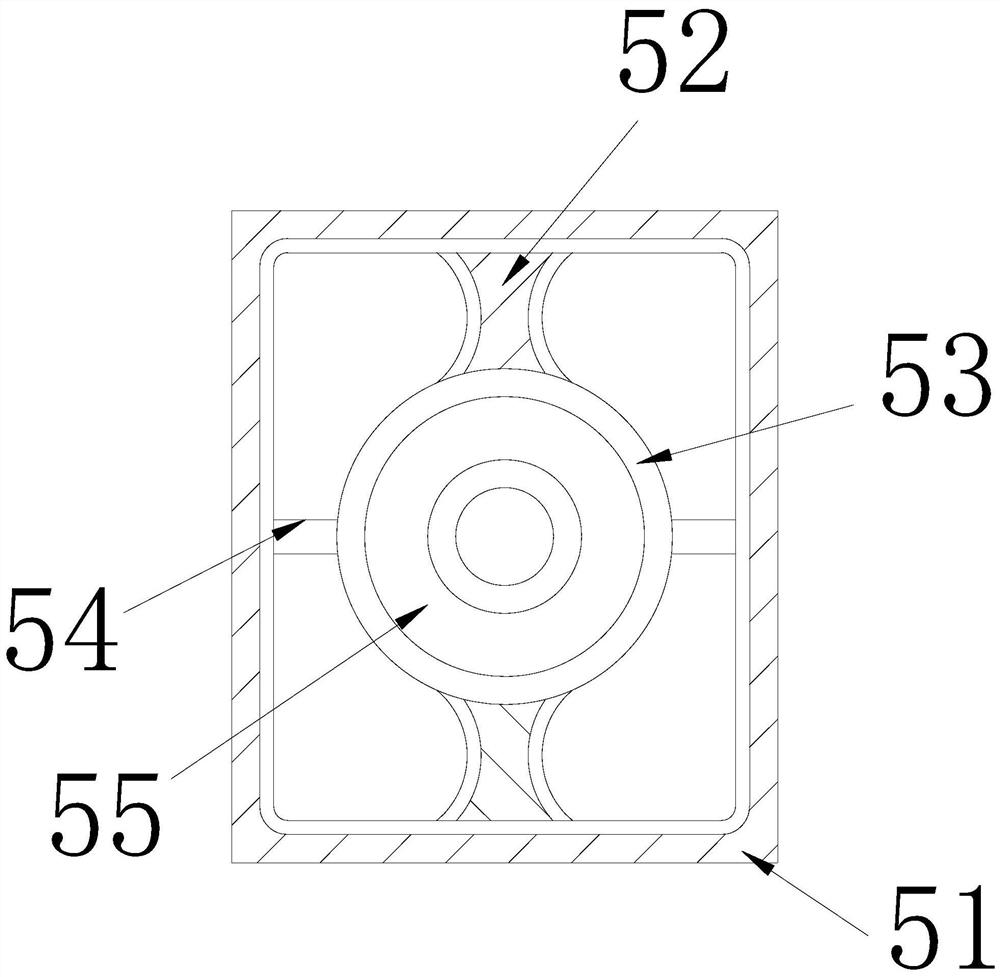

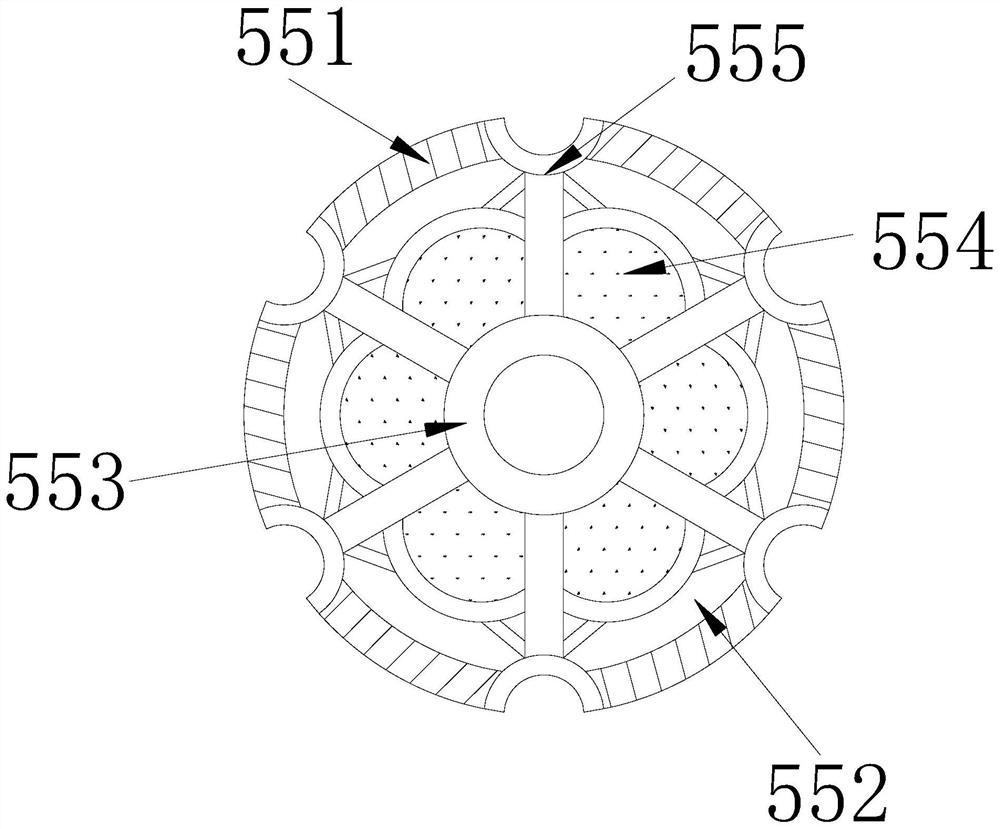

[0031] The monitoring terminal 5 is provided with a casing 51, a positioning block 52, a limiting frame 53, a wire 54, and a monitoring head 55. The inside of the casing 51 is fixedly connected to the positioning block 52, and the outside of the limiting frame 53 is connected to the positioning block 52 are attached to each other, the wire 54 runs through the limiting frame 53 and is energized with the monitoring head 55, and the positioning block 52 is respectively p...

Embodiment 2

[0039] Figure 7 to Figure 9 Shown:

[0040] The invention provides a monitoring device for food safety production,

[0041] Its structure includes that the lead-out end 555 is provided with a movable track c1, a connecting grid c2, and an ejector c3. The movable track c1 communicates with the connecting grid c2, and the ejector c3 is installed on the upper end of the movable track c1. The ejector c3 is arc-shaped, and the arc-shaped ejector c3 can effectively discharge the dust agglomerates and prevent the phenomenon of diffusion during the ejection process.

[0042] Wherein, the ejector c3 is provided with a through grid c31, an impact layer c32, an elastic ball c33, and a restricting body c34, the through grid c31 and the impact layer c32 are integrated, and the elastic ball c33 is embedded in the impact layer c32, The restricting body c34 is installed on the upper end of the impact layer c32, and the restricting body c34 is in a solid state, and the restricting body c34 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap