Steel casting vehicle device and steel casting operation method

An operation method and steel car technology, which are applied in the direction of equipment for feeding molten metal into molds, casting molten material containers, manufacturing tools, etc., can solve the problems of increasing the labor intensity of operators and the accuracy and reliability of automatic steel pouring equipment. Guaranteed, increased equipment costs and other issues, to achieve the effect of improving the utilization rate of steel pouring equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

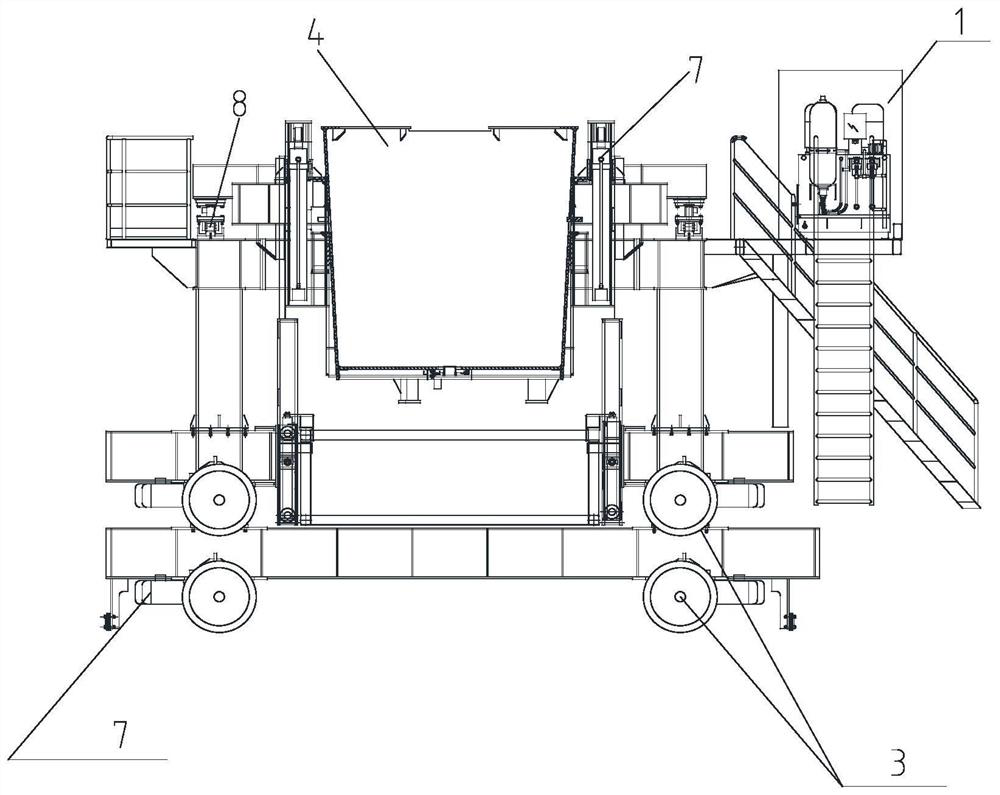

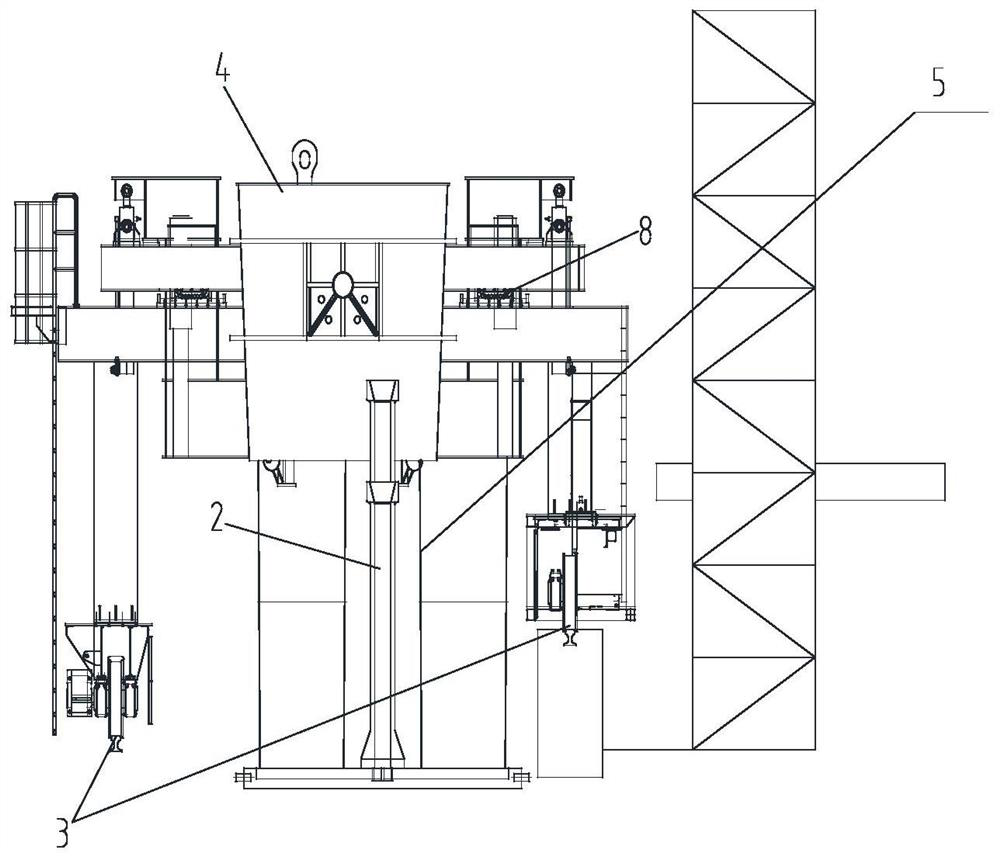

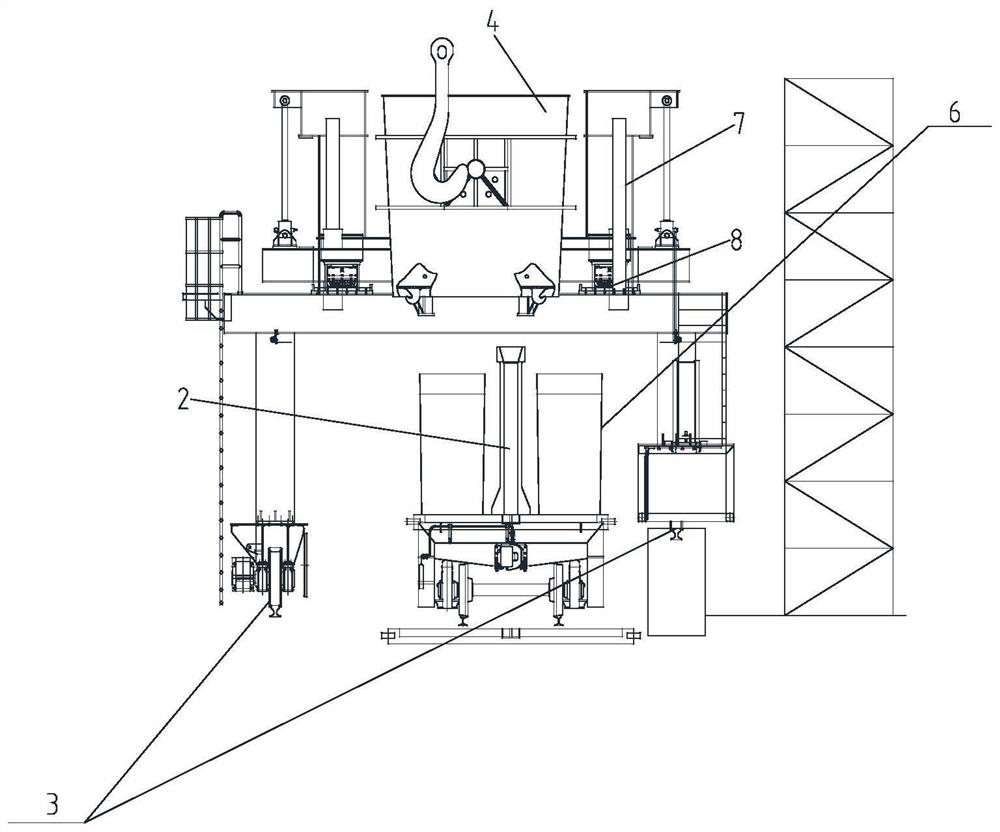

[0020] Such as figure 1 , figure 2 , image 3 The shown pouring car device includes a molten steel ladle 4 with a sprue at the bottom, a traverse device 8 and a lifting device 7 arranged on the traverse device 8, and the molten steel ladle 4 is arranged on the elevating device 7 , the traverse device 8 is arranged on the traveling transmission device 3, wherein the moving direction of the traverse device 8 and the moving direction of the traveling transmission device 3 are perpendicular to each other.

[0021] For the vehicle casting line, the molten steel ladle 4 of the automatic steel pouring vehicle can realize fixed safe pouring of steel, eliminate the operation of driving the full ladle ladle casting, and avoid the slip hook existing in the long time full ladle casting , falling bags and other catastrophic safety risks. As for the pit casting line, the molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com