Large-thickness honeycomb sandwich structure reinforcing area forming process method

A technology of honeycomb interlayer and forming process, which is applied in the field of forming process of large-thickness honeycomb sandwich structure reinforcement area, can solve the problems of poor rigidity of honeycomb, prolonging the manufacturing process of parts, difficult operation of honeycomb positioning and shaping, etc., to improve the level of preparation technology, The effect of reducing manufacturing processes and processes and saving processing equipment resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

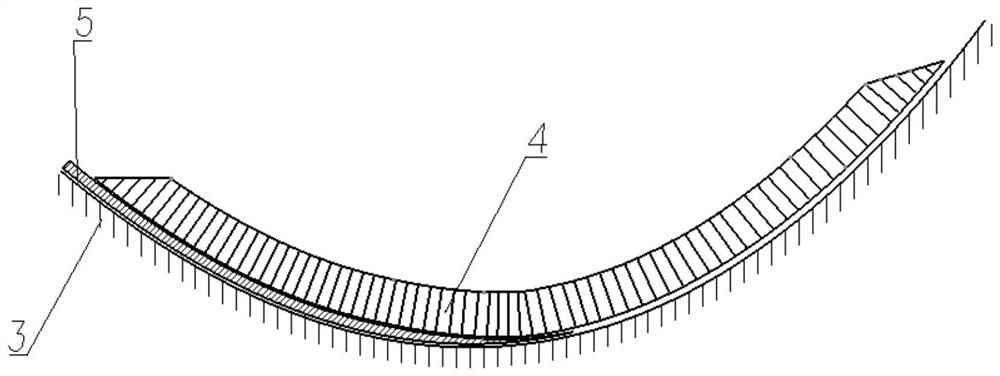

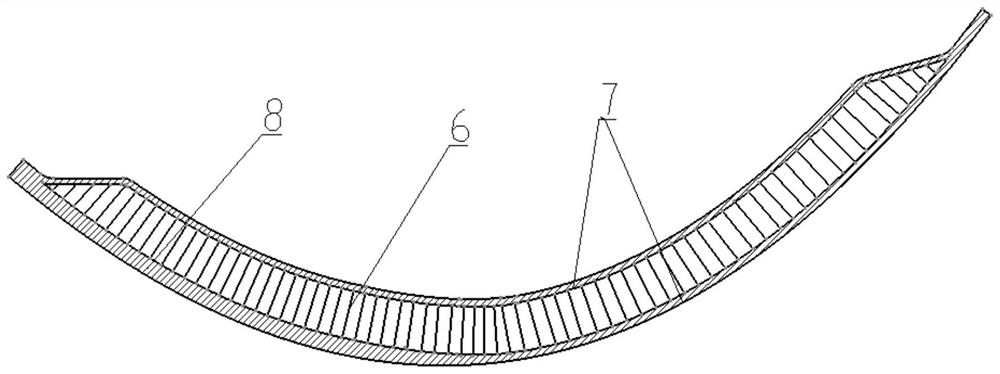

[0028] A method for forming a reinforced area of a large-thickness honeycomb sandwich structure. For a honeycomb part with a reinforced area, a gasket layer is laid on the mold surface corresponding to the position of the reinforced area, and then a large-thickness layer is placed on the mold with the gasket layer laid. Honeycomb, shape the reinforced area of the large-thickness honeycomb, stabilize the large-thickness honeycomb after shaping; then remove the large-thickness honeycomb and gasket layer, lay the reinforcement layer on the mold, and finally place the stabilized large-thickness honeycomb on the mold Structural shaping on top.

[0029] Specifically include the following steps:

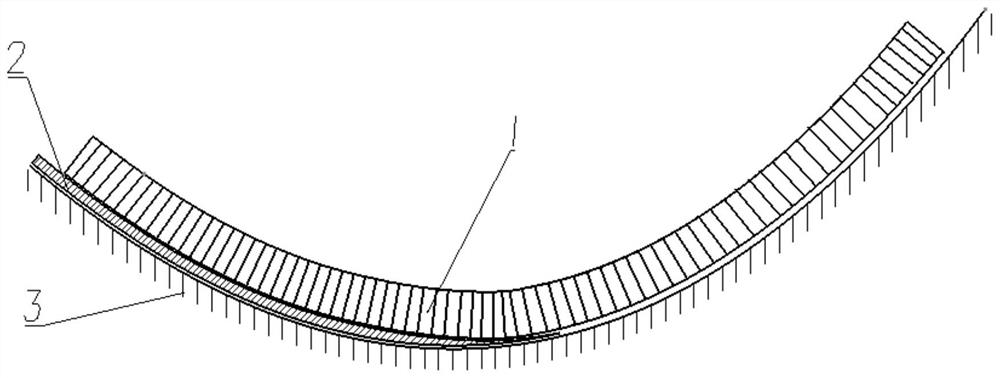

[0030] Step 1, paving the gasket layer prepreg on the profile surface of the mold, and performing reinforcement area compensation on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com