Cladding welding method applied to upright post of hydraulic support

A hydraulic support column and cladding technology, which is applied in the field of welding, can solve the problems of high cost, residual stress, and increased floating particles, and achieve the effects of short production process, environmental friendliness, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

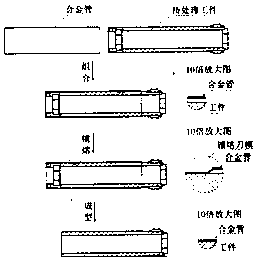

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

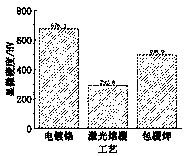

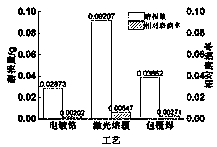

[0026] In this implementation method, three technologies of electrochrome plating, laser cladding and cladding welding are used to form the protective layer (coating) on the surface of the column, and its hardness, wear resistance, corrosion resistance and other performances are tested.

[0027] 27SiMn steel was chosen as the experimental substrate. 27SiMn has high strength and wear resistance, high hardenability, medium cold deformation plasticity, good cutting performance and acceptable welding performance.

[0028] The main chemical composition table of 27SiMn steel

[0029] element C Si mn Cr Ni P S content / % 0.27 1.20 1.25 ≤0.309 ≤0.30 ≤0.035 ≤0.035

[0030] The 27SiMn steel plate was cut, and the squares of 15mm×15mm×10 mm, 19mm×10mm×10 mm, and 10mm×20mm×1 mm were cut as the substrate, and then the copper-tin alloy was us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com