Crawler-type loading chassis, horizontal stair climbing machine and self-adaptive climbing method

A crawler and crawler technology, which is applied in the field of horizontal stair climbing machine and self-adaptive climbing, crawler load chassis, can solve the problems of low safety factor, overturning, forward tilting, etc., and achieve smooth and safe climbing. The effect of high coefficient and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

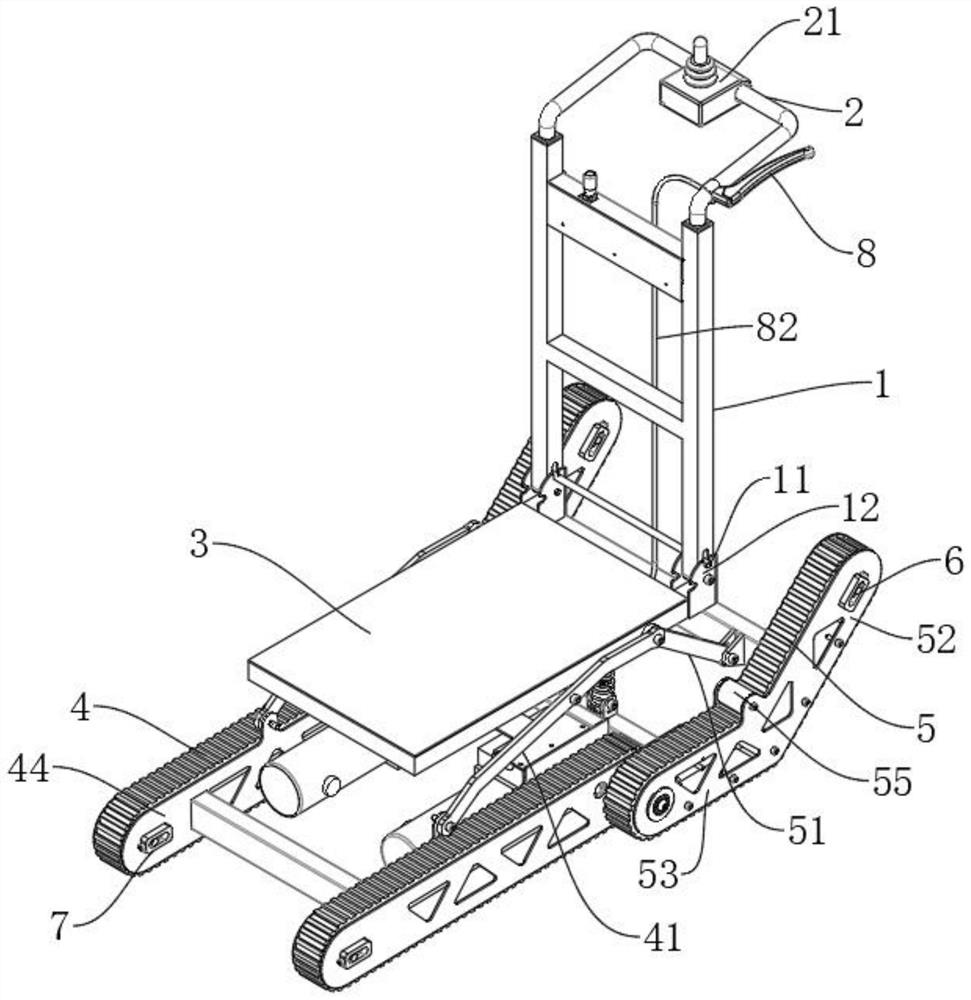

[0055] Such as Figure 1-12 As shown, the present embodiment proposes a height-adjustable vehicle frame, including a vehicle frame 1 and a loading platform 3, a guide seat 23 is connected between the vehicle frames 1, a handlebar 2 is slidably connected to the vehicle frame 1, and the guide seat 23 At least one moving bar 24 is slidably connected, and the guide seat 23 is also rotatably connected with a turning bar 26; There are several positioning holes 28 matched with the moving rod 24 .

[0056] The vehicle frame 1 is provided with a sliding groove along the length direction, the handlebar 2 is slidably arranged in the sliding groove, and several positioning holes 28 are arranged along the lengthwise direction of the handlebar 2 and are all matched with the moving rod 24, thereby facilitating the movement of the moving rod 24 into the positioning hole 28, so as to realize the relative fixing of the position of the handlebar 2.

[0057] Considering the fixing effect on the...

Embodiment 2

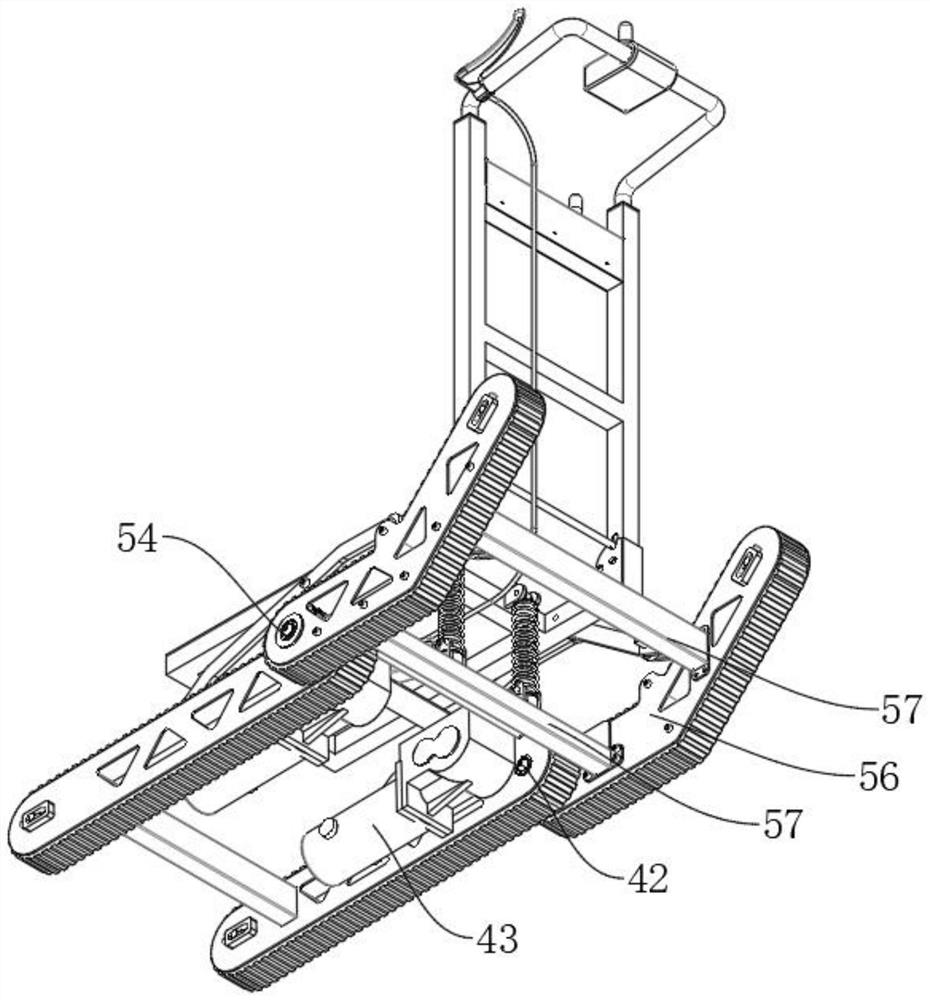

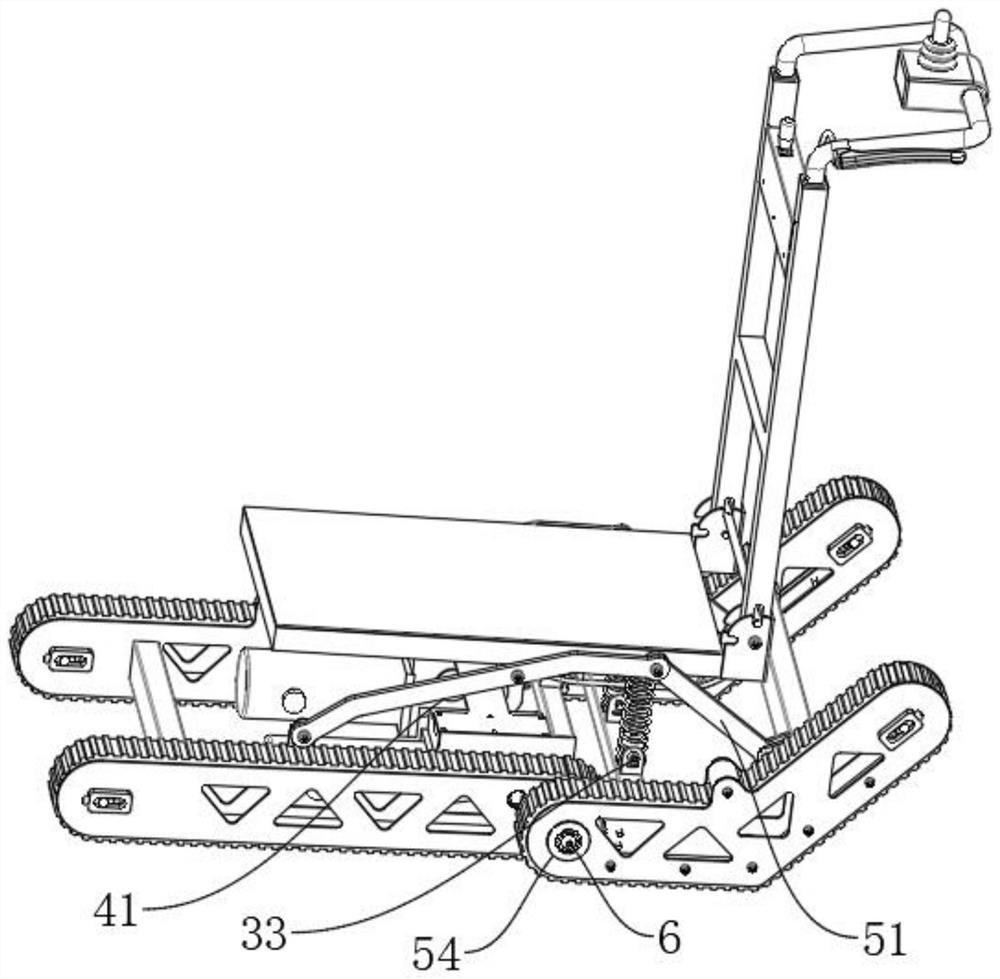

[0066] Such as Figure 1-12 As shown, this embodiment proposes a crawler-type loading chassis, including the height-adjustable vehicle frame described in Embodiment 1, wherein the two sides of the loading platform 3 are respectively hinged with front rotating rods 51 and rear rotating rods 41. The track assembly and the rear track assembly, the front track assembly includes a front track segment 52 and a rear track segment 53, a first angle is formed between the rear track segment 53 and the front track segment 52, and the first angle is an obtuse angle.

[0067] It also includes: a rotating shaft 6, the rotating shaft 6 is arranged at the rear end of the front crawler assembly or close to the rear end, and at the same time the rotating shaft 6 is arranged at the front end of the rear crawler assembly or near the front section;

[0068] Telescopic mechanism 31, the front crawler assembly and / or the rear crawler assembly are hinged to the loading platform 3 through the telescop...

Embodiment 3

[0094] Such as Figure 1-12 As shown, this embodiment proposes a horizontal stair climbing machine, including the above-mentioned crawler-type load-carrying chassis, and the front track wheels and the rear track wheels are respectively connected with independent driving mechanisms or the same driving mechanism drives the front track wheels and rear track wheels turn.

[0095] When using an independent drive mechanism, the drive mechanism drives the front crawler belt 5 and the rear crawler belt 4 to rotate respectively.

[0096] When the same driving mechanism is used, the driving mechanism is a driving motor 43, and there are two driving motors 43, which are fixedly connected with two rear crawler brackets 44 respectively.

[0097] Rotating shaft 6 fixed cover is provided with rear crawler wheel 42 and front crawler wheel 54, and rotating shaft 6 runs through rear crawler support 44 and front crawler support 56, and rear crawler support 44 and front crawler support 56 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com