Rapid winding auxiliary equipment for intelligent manufacturing of power cables

A power cable and intelligent manufacturing technology, applied in the field of intelligent manufacturing power cable fast winding auxiliary equipment, can solve the problems of uneven and tidy cables, lack of lateral movement, slow winding frame speed, etc., and achieves convenient operation and structure. Simple and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

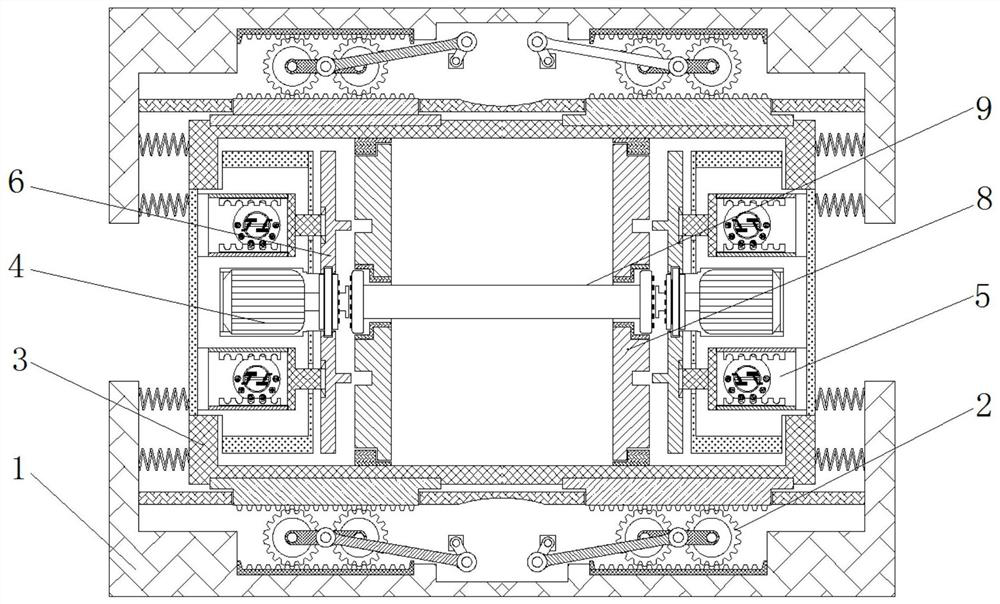

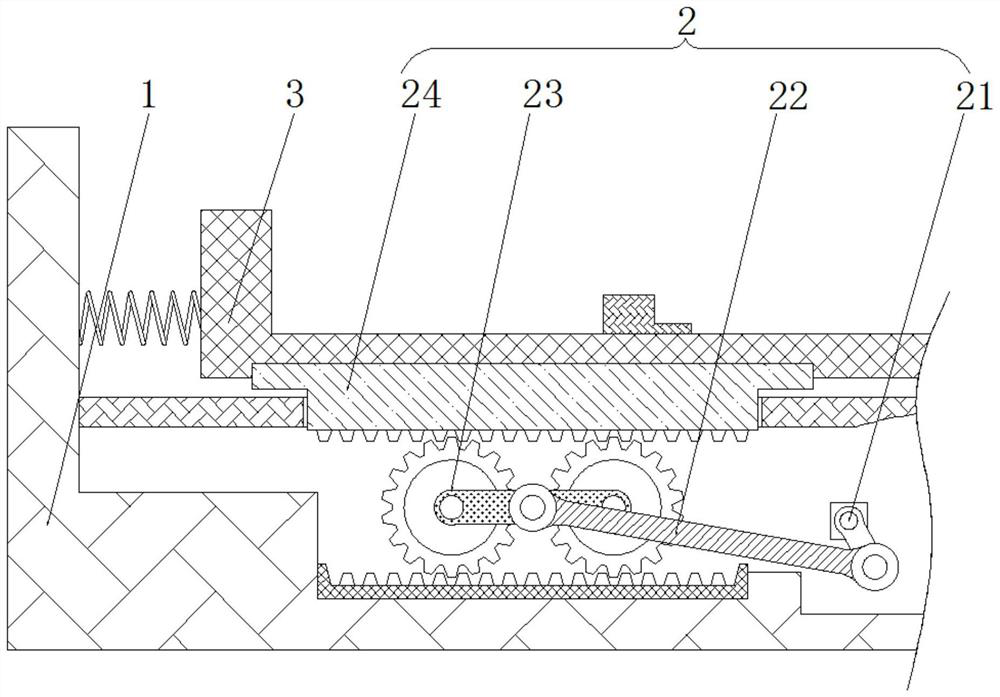

[0028] see Figure 1-3 , an auxiliary equipment for quick winding of intelligent manufacturing power cables, including a mounting frame 1, a sliding mechanism 2 is movably connected above the mounting frame 1, and the sliding mechanism 2 includes a Z-shaped crankshaft 21, and a diagonal is movably connected to the outside of the Z-shaped crankshaft 21. Pull rod 22, the outer section of the diagonal tie rod 22 is movably connected with a driven gear 23, the driven gear 23 is composed of two gears, the gear shafts of the two gears are movably connected through the connecting plate, and the outer end of the diagonal tie rod 22 is hinged on the connecting plate Above, the outer side of the driven gear 23 is movably connected with a tooth plate 24, the tooth plate 24 is provided with two sets of upper and lower groups, and the lower tooth plate 24 is fixedly connected with the mounting frame 1, and the upper tooth plate 24 is movably connected with the bearing plate 3, and The outs...

Embodiment 2

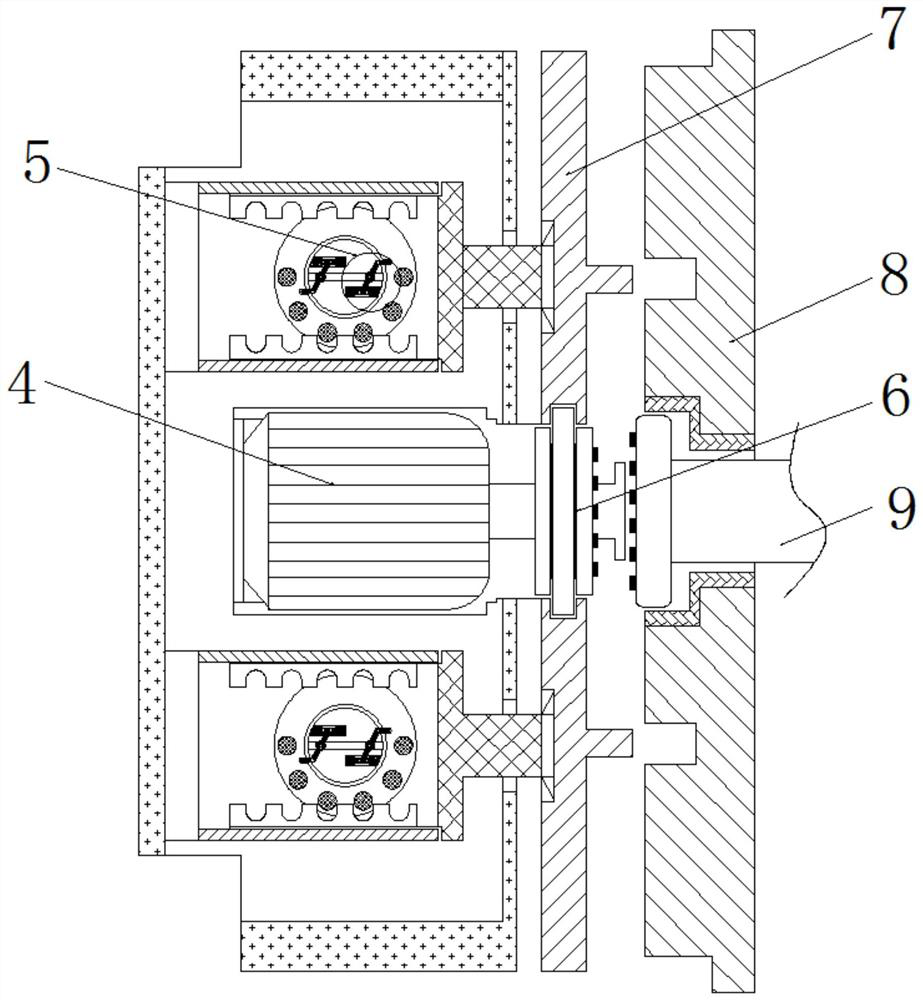

[0030] see figure 1 , Figure 3-5 , an auxiliary equipment for fast winding of intelligent manufacturing power cables, including a mounting frame 1, a sliding mechanism 2 is movably connected above the mounting frame 1, a bearing plate 3 is movably connected above the sliding mechanism 2, and a bearing plate 3 is movably connected above There is a winding motor 4, and the outer side of the winding motor 4 is movably connected with a propulsion mechanism 5, wherein the mounting frame 1 is composed of an inner bracket and an outer bracket, wherein the sliding mechanism 2 is movably connected to the inner side of the outer bracket, and the winding motor 4 and the propulsion mechanism 5 It is flexibly connected to the inside of the inner bracket, and a buffer spring is arranged between the inner bracket and the outer bracket. Projection, propulsion mechanism 5 comprises moving frame 51, and the inboard of moving frame 51 is movably connected with driving wheel 52, and the inner s...

Embodiment 3

[0032] see Figure 1-5, an auxiliary equipment for quick winding of intelligent manufacturing power cables, including a mounting frame 1, a sliding mechanism 2 is movably connected above the mounting frame 1, and the sliding mechanism 2 includes a Z-shaped crankshaft 21, and a diagonal is movably connected to the outside of the Z-shaped crankshaft 21. Pull rod 22, the outer section of the diagonal tie rod 22 is movably connected with a driven gear 23, the driven gear 23 is composed of two gears, the gear shafts of the two gears are movably connected through the connecting plate, and the outer end of the diagonal tie rod 22 is hinged on the connecting plate Above, the outer side of the driven gear 23 is movably connected with a tooth plate 24, the tooth plate 24 is provided with two sets of upper and lower groups, and the lower tooth plate 24 is fixedly connected with the mounting frame 1, and the upper tooth plate 24 is movably connected with the bearing plate 3, and The outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com