Pre-cleaning structure of washing machine and washing machine

A pre-cleaning, washing machine technology, applied in the field of washing machines, can solve the problems of washing water cannot be excluded, no manual drainage structure is provided, etc., and achieve the effects of avoiding the failure of drainage, facilitating realization, and increasing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

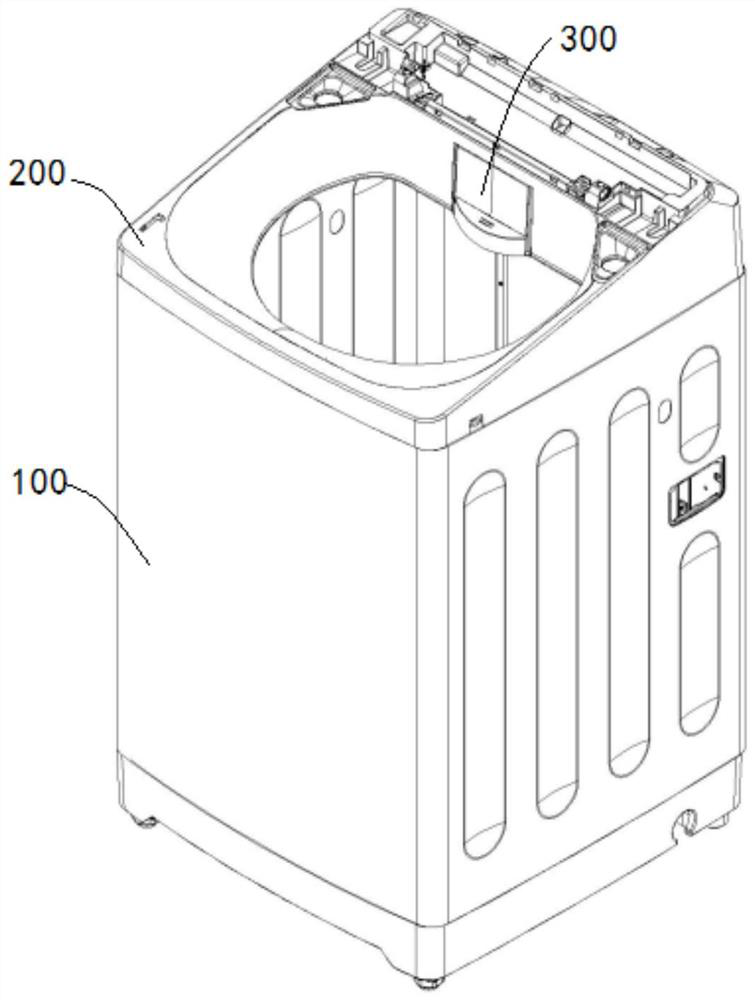

[0053] see Figure 1-Figure 16 , is an embodiment of the washing machine pre-cleaning structure proposed by the present invention. The washing machine includes a box body 100, a control panel base 200 arranged on the box body 100, and a pre-cleaning structure 300 is arranged on the control panel base 200; the pre-cleaning structure 300 is set in the washing machine, after pre-cleaning the neckline, cuffs and other local parts of the clothes, the clothes can be directly put into the washing tub for regular washing, without redundant operations, and the operation is simple and convenient. The pre-cleaning structure 300 is provided with an ultrasonic transducer 40 to realize partial pre-cleaning of the clothes.

[0054] Before washing, the user can make a preliminary judgment on the degree of dirt on the part of the clothes to be washed, and if it is believed that the washing effect can be achieved through normal washing, it is not necessary to go through the ultrasonic cleaning ...

Embodiment 2

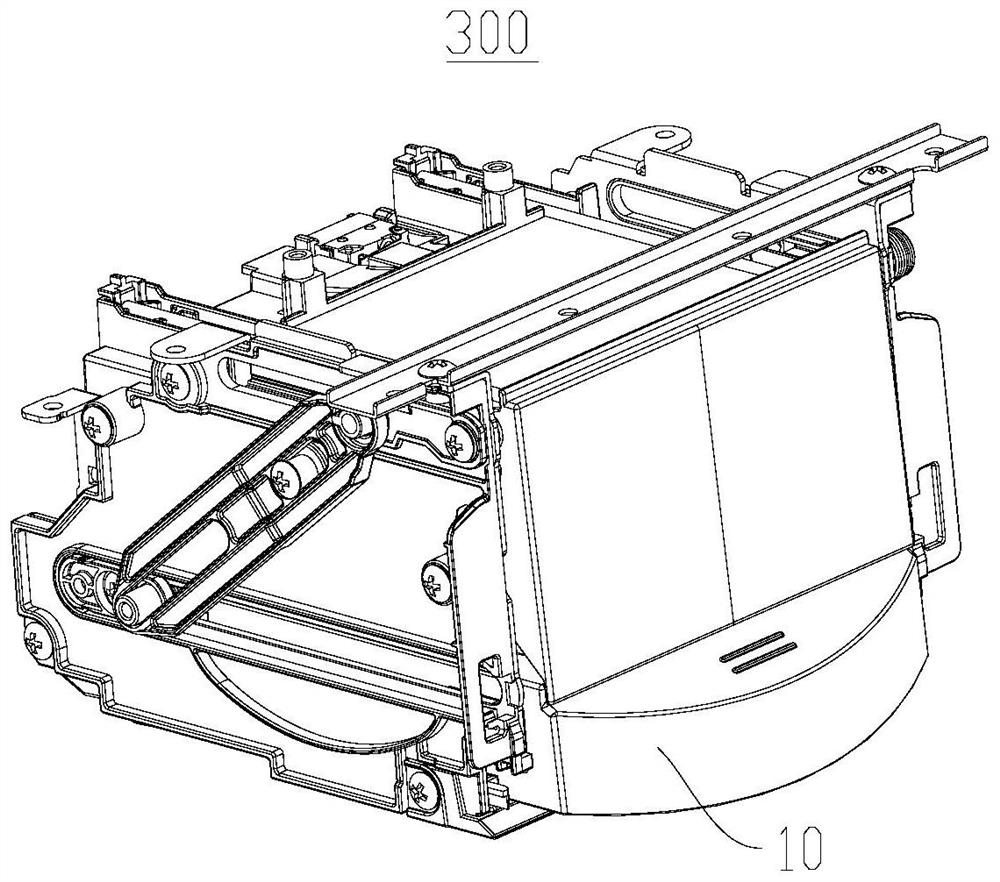

[0059] see Figure 1-Figure 16 , a washing machine pre-cleaning structure 300 includes: a water tray 10 and a drainage control frame 20, the water tray 10 is used to hold the washing water for pre-cleaning, the drainage control frame 20 is slidably arranged on the water tray 10, and the drainage control frame 20 It is used to control the drainage of the water tray 10; the water tray 10 is provided with a drain outlet 11, and the drainage control frame 20 is provided with a plug 21 that can open and close the drain outlet 11.

[0060] In this embodiment, the water tray 10 can be pushed and pulled, and can be pushed into the control panel seat 200 when not in use, so as not to interfere with the normal washing of the washing machine. The drainage control frame 20 slides relative to the water tray 10 in the push-pull direction of the water tray 10, that is, the sliding direction of the drainage control frame 20 on the water tray 10 is consistent with the push-pull direction of th...

Embodiment 3

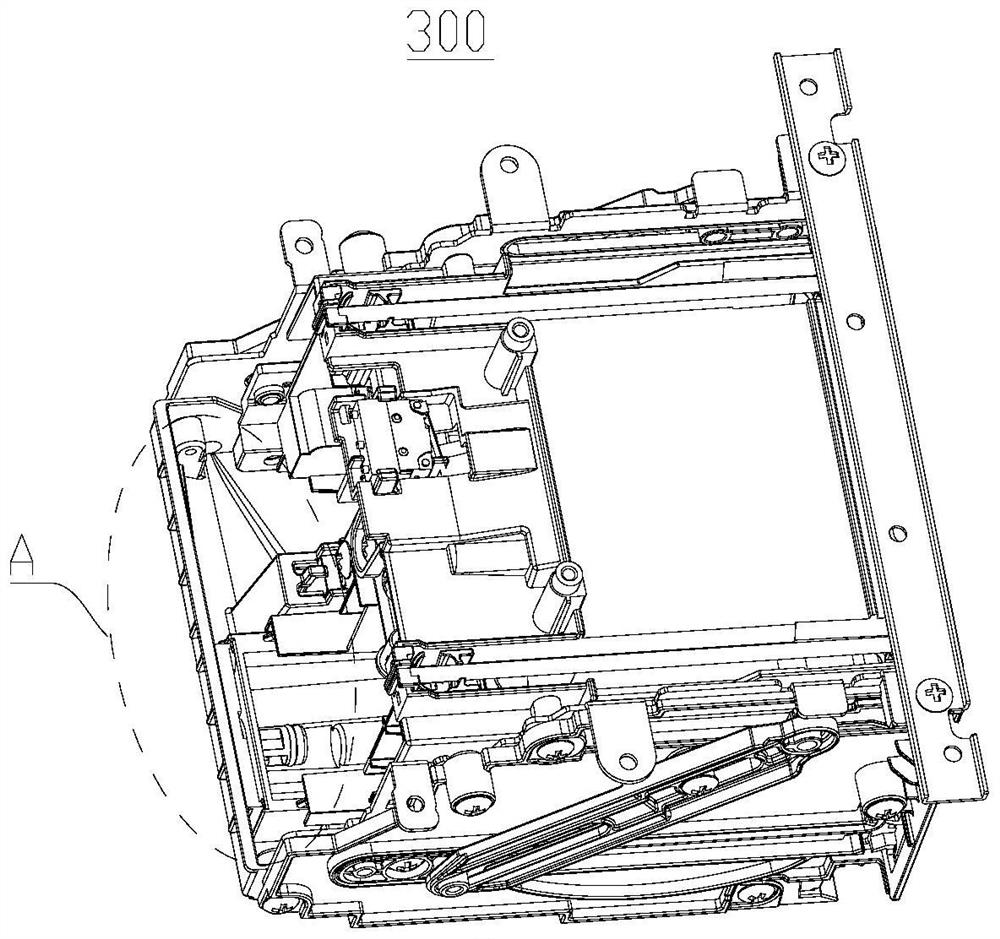

[0073] see figure 1 , a washing machine pre-cleaning structure 300 includes: a water tray 10 and a drainage control frame 20, the water tray 10 is used to hold the washing water for pre-cleaning, the drainage control frame 20 is slidably arranged on the water tray 10, and the drainage control frame 20 It is used to control the drainage of the water tray 10; the water tray 10 is provided with a drain outlet 11, and the drainage control frame 20 is provided with a plug 21 that can open and close the drain outlet 11.

[0074] A method for manually controlling the sliding of the drain control frame 20 is described. A push port 15 is provided on the water tray 10, and a push plate 25 located inside the push port 15 is provided on the drain control frame 20. One end of the push plate 25 is connected to the drain control The frame 20 is connected, that is, the push plate 25 is provided as a cantilever; In the state where the plug 21 seals the drain port 11, push the push plate 25 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com