Self-climbing safety operation platform for pouring construction of pier column and construction method thereof

A safe operation and self-climbing technology, applied in the field of bridge construction, can solve the problems of wasting manpower, heavy construction work, and use, and achieve the effects of avoiding waste, reducing work difficulty, and reducing physical burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

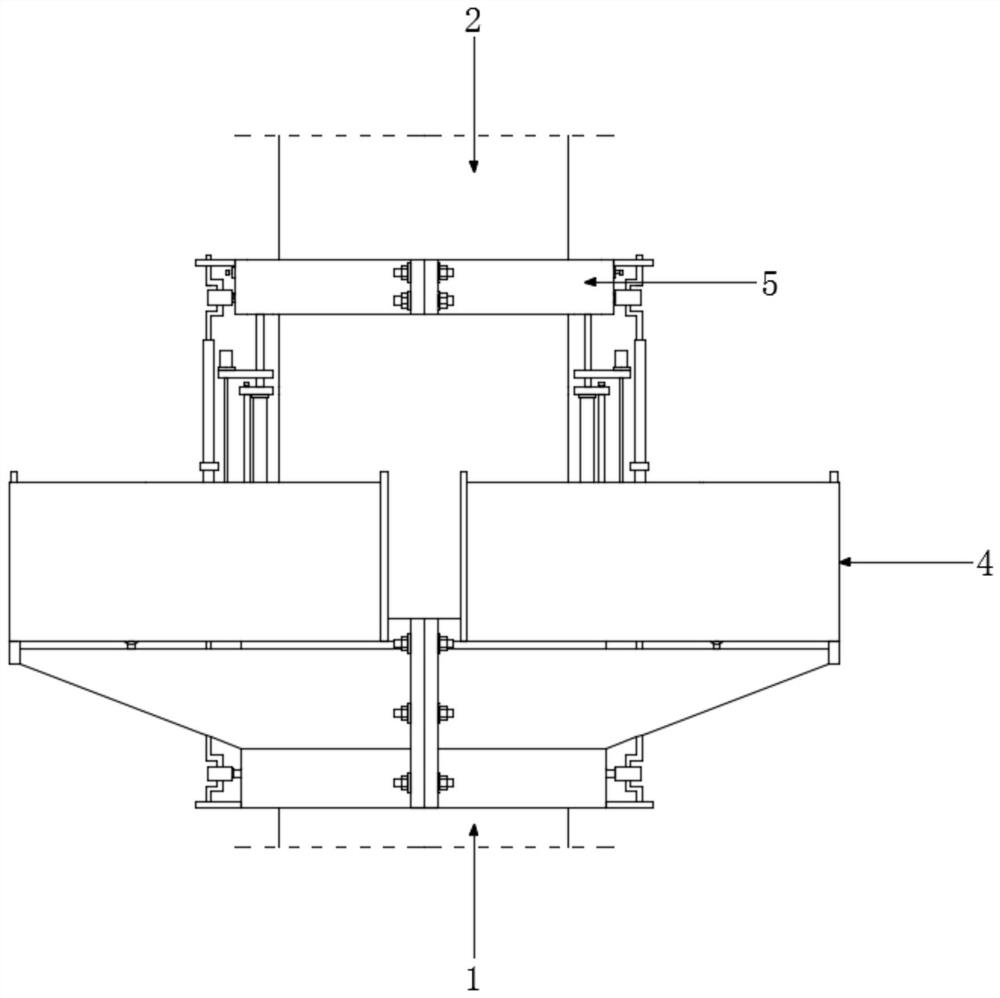

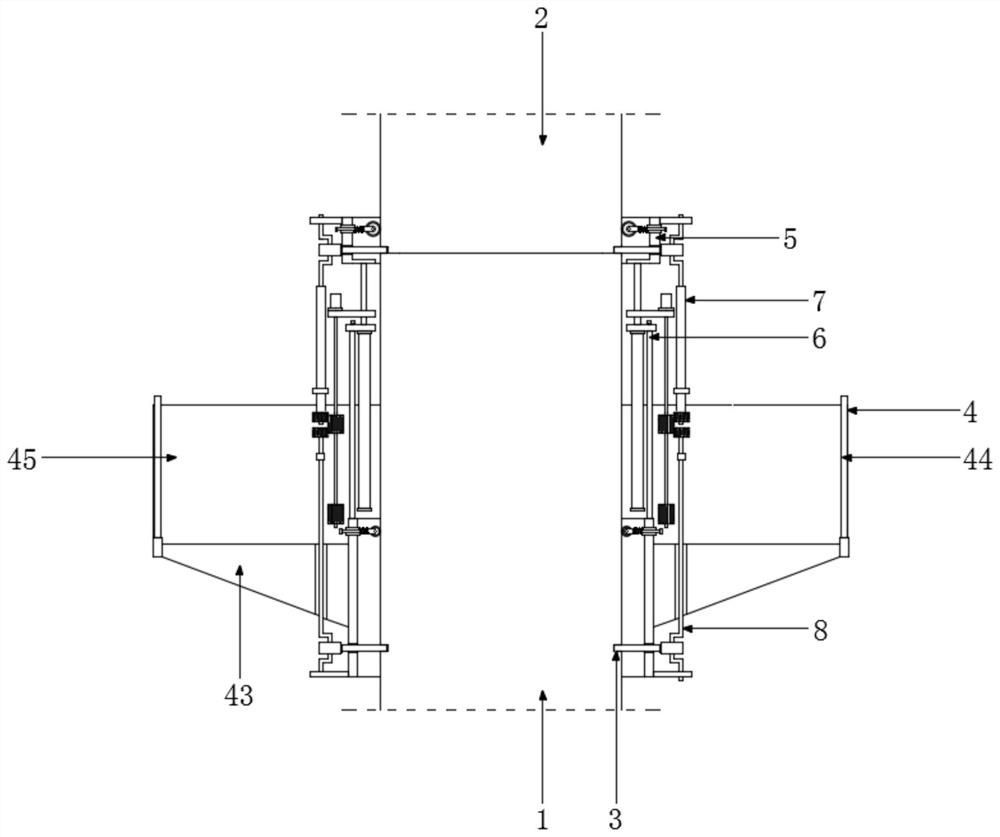

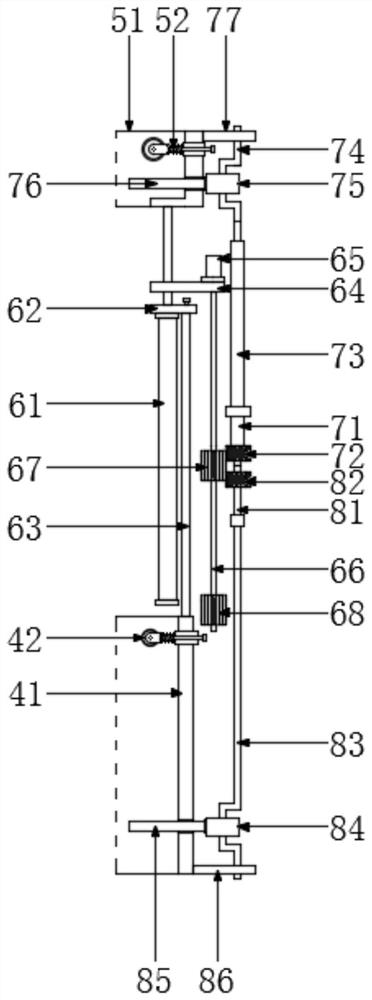

[0035] The present invention provides such Figure 1-5 A self-climbing safe operation platform for pier column pouring construction is shown, including a first pier column pouring section 1 and a second pier column pouring section 2, and the second pier column pouring section 2 is fixedly arranged on the first pier column pouring section. The top of section 1, the middle part of the outer side of the first pier column pouring section 1 and the outer bottom of the second pier column pouring section 2 are circularly opened with multiple pouring holes 3, and the outer side of the first pier column pouring section 1 is socketed with a workbench assembly 4 , a suspension assembly 5 is socketed on the outer side of the bonding surface of the first pier column pouring section 1 and the second pier column pouring section 2 .

[0036] At the same time, both sides of the first pier column pouring section 1 are provided with a lifting drive mechanism 6, an upper locking mechanism 7 and a...

Embodiment 2

[0052] Different from the above-mentioned embodiments, during the pouring process of the pier columns, technicians found that the first arc-shaped mounting plate 41 and the second arc-shaped mounting plate 51 are prone to shake when they are raised and lowered, and it is easy to operate on the top of the platform 43 In order to avoid the occurrence of the above situation:

[0053] Parts A and B also include a first elastic support mechanism 42, which is fixed on the top inside the first arc-shaped mounting plate 41, and parts C and D also include a second elastic support mechanism 52, the second elastic The support mechanism 52 is fixedly arranged on the inner top of the second arc-shaped mounting plate 51, and the first elastic support mechanism 42 and the second elastic support mechanism 52 both include a sliding sleeve 521, a sliding rod 522, a moving wheel 523 and a spring 524. The sliding sleeve 521 in the elastic support mechanism 42 is fixedly nested on the first arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com