Suspension combination assembly type super high-rise building cantilever structure and construction method

A combined assembly, super high-rise technology, applied in the direction of building structure, building, housing structure support, etc., can solve the problems of rollover danger, rollover and other problems, and achieve the effect of easy movement and increased practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

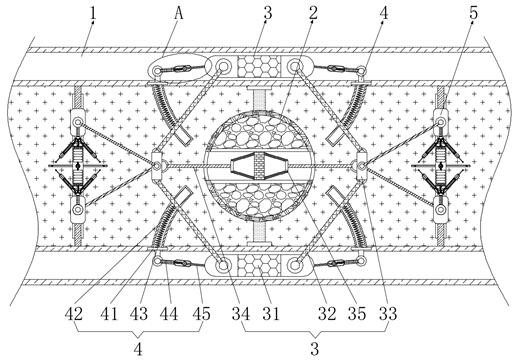

[0036] see figure 1 , 5, a cantilevered structure of a suspended combined assembled super high-rise building, comprising a frame body 1, the interior of the frame body 1 is slidingly connected with a counterweight 2, and the upper and lower sides of the frame body 1 are movably connected with a safety mechanism 3, and the safety mechanism 3 includes Driven block 31, connecting rod 32, carrying block 33, push rod 34, spring plate 35, the left and right sides of driven block 31 are connected with connecting rod 32, and the other end of connecting rod 32 is connected with carrying block 33, carries One end of the block 33 close to the counterweight 2 is fixedly equipped with a spring plate 35, the inside of the counterweight 2 is provided with a groove, the spring plate 35 is slidably connected to the inside of the groove, and the movement of the spring plate 35 drives the counterweight 2. To move, the left and right sides of the safety mechanism 3 are movably connected with a t...

Embodiment 2

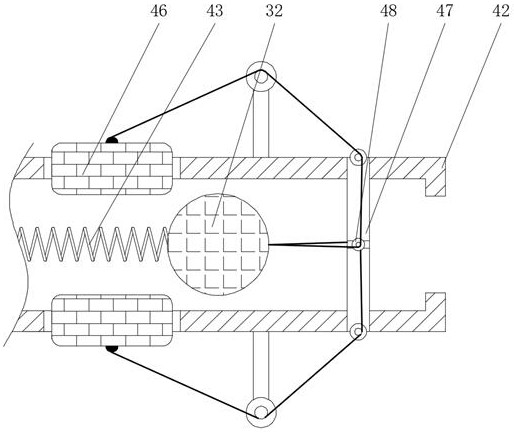

[0038] see figure 1 , 2 , 4, a kind of cantilever structure of the super high-rise building of suspension combined assembly type, comprises frame body 1, and the inside of frame body 1 is slidingly connected with counterweight 2, and the upper and lower sides of frame body 1 is movably connected with safety mechanism 3, and safety mechanism The left and right sides of 3 are movably connected with a trigger mechanism 4, and the trigger mechanism 4 includes a support plate 41, an arc groove 42, a buffer spring 43, a fixed sleeve 44, a buffer rod 45, a baffle plate 46, a pole 47, and a winding group 48, One end of the support plate 41 close to the center of the frame body 1 is fixedly equipped with an arc-shaped groove 42, and the inside of the arc-shaped groove 42 at the top of the support plate 41 is elastically connected with a buffer spring 43, and the end of the support plate 41 away from the arc-shaped groove 42 is rotatably connected with a fixed sleeve 44, the inside of ...

Embodiment 3

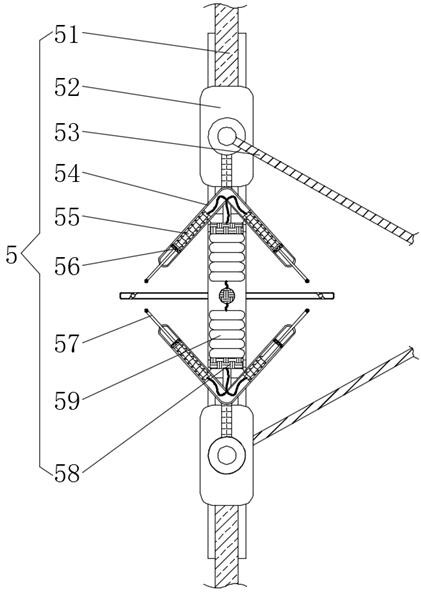

[0040] see figure 1 , 3 , 6, a kind of cantilever structure of super high-rise building of suspension combined assembly type, comprises frame body 1, and the inside of frame body 1 is slidingly connected with counterweight 2, and the upper and lower sides of frame body 1 is movably connected with safety mechanism 3, and safety mechanism The left and right sides of 3 are movably connected with a trigger mechanism 4, and the left and right sides of the counterweight 2 inside the frame body 1 are fixedly connected with a stabilizing mechanism 5, and the stabilizing mechanism 5 includes a fixed rod 51, a slider 52, a connecting rod 53, and a curved groove 54 , electromagnet 55, magnetic block 56, positioning pin 57, contact 58, resistance strip 59, the upper and lower sides of fixed rod 51 are slidably connected with slider 52, and the end of slider 52 close to counterweight 2 is connected with connecting rod in rotation 53, a curved groove 54 is fixedly installed at one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com